Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.

Standard Lithium

5,322 followers

12h •

Proud to share the HIGHEST-EVER lithium brine grade reported in North America from our East Texas expansion program: 806 mg/L! Our results also include significant potash and bromine concentrations, all from areas where we have rights to all minerals contained in the brine.

Learn more>>> https://lnkd.in/gcmNmrYN

Image below is ETX New Well #3 - the source of 806 mg/L and 739 mg/L results

Standard Lithium’s East Texas Drilling Program Delivers New Highest Confirmed Grade Lithium Brine in North America

EL DORADO, Ark., Oct. 10, 2023 (GLOBE NEWSWIRE) -- Standard Lithium Ltd. (“Standard Lithium” or the “Company”) (TSXV:SLI) (NYSE American:SLI) (FRA:S5L), a leading near-commercial lithium company, today announced it has drilled and sampled, to the best of its knowledge, a new highest confirmed lithium grade brine in North America, with a grade of 663 mg/L lithium. The results reflect lithium sample analyses from a newly drilled well from the Company’s significant expansion work in the East Texas Smackover region.

Dr. Andy Robinson, President and COO of Standard Lithium commented, “We continue to be very excited by the quality and scale of the lithium brine assets we’re adding in East Texas. The lithium sample analysis from a newly-drilled well delivered, to the best of our knowledge, a new highest-grade lithium brine concentration in North America and confirmed that we are securing the highest-grade lithium brine resource outside of Chile and Argentina. We continue to expand our footprint in the East Texas Smackover and de-risk the opportunity with additional drilling, sampling and definition work.”

“East Texas is a significant addition to our two more advanced projects in Arkansas, the Phase 1A and South West Arkansas Projects,” added Dr. Robinson. “We expect our East Texas landholdings to form a substantially larger and higher-grade lithium brine project for future production. Standard Lithium will continue to progress its portfolio of projects to help meet U.S. demand for lithium over the next decade.”

Standard Lithium Files Definitive Feasibility Study for its First Commercial Lithium Extraction Plant – Phase 1A

EL DORADO, Ark., Oct. 18, 2023 (GLOBE NEWSWIRE) -- Standard Lithium Ltd. (“Standard Lithium” or the “Company”) (TSXV:SLI) (NYSE American:SLI) (FRA:S5L), a leading near-commercial lithium company, today announced that the Definitive Feasibility Study (the “Report”) for its first commercial lithium project (“Phase 1A”) proposed to be located at the LANXESS South Plant has been filed.

With expected first production in 2026, Phase 1A is anticipated to be the first US-based lithium production project built in six decades, and the first commercial direct lithium extraction facility in North America with potential to double current United States lithium production from current levels.

Phase 1A will process lithium-rich brine currently flowing through existing infrastructure and represents production of only five percent of the total Measured and Indicated Resource of 2.8 Mt lithium carbonate equivalent (“LCE”)¹. The Definitive Feasibility Study demonstrates strong economics, assuming initial annual production of 5,700 tonnes, and an average annual production of 5,400 tonnes of battery-quality lithium carbonate over a 25-year operating life based on Proven and Probable Reserves of 208 Kt LCE at an average concentration of 217 mg/L. Phase 1A represents a modest 60-times scale up from the operational Demonstration Plant, which over a three-and-a-half-year period of effective and efficient lithium extraction, has used the same brine that will feed the proposed commercial plant. The Company expects to make a final investment decision for Phase 1A in the first half of 2024.

About to take a starter position, any input from board ( either way) appreciated:)

Well it looks like I was figuring it would go .10 cents lower but evidently I was wrong.

That December 29th chart low WAS the tax-loss selling buy of perhaps I dunno - a decade.

It's currently testing its' up 50% ! 2 month uptrend !tho .....

Is totally potentially vulerable now. That was just absurd.

This January / February has been hard to buy into ANY EV metal plays for me.

I get wrapped up watching Bitcoin for fun. It's overly entertaining.

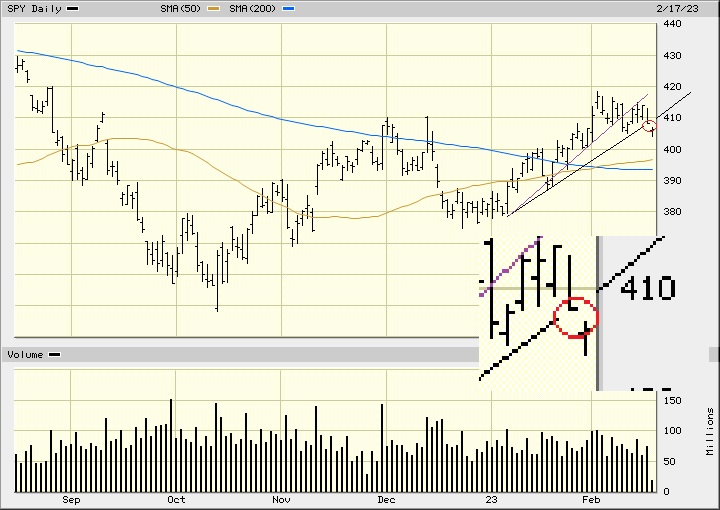

I've monitored the S&P doing this here (it's NOW at 399) ;

Between interest rate decisions, surprise holiday weekends, earnings volatility, etc., etc. it's......like -

it's tempting to get someone else to do it

.

It's like monitoring all of this stuff is just nuts - iT'S LIKE DRIVING a submarine

For eg. : So why is the IHub chart symbol all messed up here ?

Who wants to navigate that ?

Get it changed from London to of course its' Toronto listing.

.

Nice pull back up.

Thanks for your input (or should I say "output").....Whichever, thanks for your efforts.

Yet, so just WHAT is "the problem" for, there sure seems to BE one ?

What the heck could I be "missing" ?

Or, perhaps it's just caught in a "technical selloff" down to the (soon-to-be revisted historical) $3.75 level ?

Where I should have a horizontal line drawn / included.

Thanks again tho......as I may TRY to re-view it......

Unfortunately my (lazy) "prediliction" is to simply......just "go by the chart(s)" !

ha 1

.

.

.

Sorry it took so long for me to find it. Been some time since I went through SLI fillings.

Page 10

On April 23, 2018 the Company entered into an exploration and option agreement (“EOA”), with TETRA

Technologies, Inc. (“TETRA”), to secure access to additional operating and permitted land consisting of

approximately 12,100 acres in Bristol Dry Lake, and up to 11,840 acres in the adjacent Cadiz Dry Lake, Mojave

Desert, California. The EOA with TETRA allows for the exclusive right to negotiate and conduct exploration

activities and to enter into a mineral lease to allow exploration and production activities for lithium extraction

on property held under longstanding mining claims and permits by TETRA.

https://d1io3yog0oux5.cloudfront.net/_b58c4235cb1a7516a5c96430e7c23fcb/standardlithium/db/385/2045/file/SLI+Financial+Statements+Q1-23+September+30+2022+FINAL+%28003%29.pdf

Mojave Project

45,000+ acre project, covers majority of the playa; overlies basin estimated to be >1,000 m deep.

Two active, permitted, brine processing companies that have operated for decades producing industrial minerals from brines at Bristol Dry Lake.

Agreements signed with both permitted operators provide immediate access to raw brine, evaporation ponds, decades of operational expertise & existing mining permits.

Existing infrastructure, paved road and rail at site, abundant electricity & water, skilled workforce, close to Port of Long Beach (deep-water seaport).

Access to private land; substantially reducing permitting risk for process plant siting and operation.

https://www.standardlithium.com/projects/bristol-lake

ARKANSAS’ BRINE PRODUCTION BUSINESS

HOW YOU MAKE SOMETHING FROM LESS THAN NOTHING

By Thomas A. Daily1

https://iogcc.ok.gov/sites/g/files/gmc836/f/documents/2021/brine_paper.pdf

FACT SHEET for the UNDERGROUND INJECTION CONTROL PROGRAM

in ARKANSAS

TYPES of INJECTION WELLS:

https://www.adeq.state.ar.us/water/permits/nodischarge/pdfs/uic_fact_sheet.pdf

Optimized Process Designs LLC (OPD) provides clients with detailed engineering packages in all disciplines, single-point procurement for all equipment and materials, fabrication and direct-hired construction services at project locations throughout the United States.

https://www.opdepc.com/

highfeather, I need to correct that post, that you commented on..

SLI is already doing work at that facility. Which means in Arkansas, it would be an amendment to existing permit, all States are different. I read many States last night.

This project contemplates processing the brine that is currently being handled by Lanxess at its South Facility, where the Company’s continuously operating pre-commercial Direct Lithium Extraction (DLE) Demonstration Plant is located.

Recent Clients

Bottom of page.

https://chemionex.com/

Perhaps investigate Critical Elements ? - They just got their Quebec permit.

https://investorshub.advfn.com/boards/read_msg.aspx?message_id=159605611

I'm not too crazy about Quebec developers but that's a whole nuther story.

https://www.cecorp.ca/en/investors/news-releases/

I probably low balled that number.

How did you determine that it will take 3-5 years for permits to be issued? Seems excessive.

Thanks for posting the announcement on the new plant. How did you determine that it will take 3-5 years for permits to be issued? Seems excessive.

Standard Lithium Signs Key Agreement to Advance Design of First Commercial Lithium Plant

December 06, 2022 6:00am EST

(Watch how many years it takes to get their permit. It well take 3 to 5-years)

I'll be getting dividens from SYAXF before SLI even starts production.

Design and Site Work Underway for Company’s First Commercial Lithium Plant

EL DORADO, Ark., Dec. 06, 2022 (GLOBE NEWSWIRE) -- Standard Lithium Ltd. (“Standard Lithium” or the “Company”) (TSXV: SLI) (NYSE American: SLI) (FRA: S5L), a leading near-commercial lithium company, is pleased to announce it has completed all necessary agreements with LANXESS Corporation to secure access to the proposed commercial lithium plant site (the “Site Access Agreement”) and conduct all required fieldwork to support the Definitive Feasibility Study (DFS) underway. Standard Lithium is also pleased to report that subsequent to signing the Site Access Agreement, the Company has commenced the site work necessary for the design of its first commercial lithium plant.

https://www.standardlithium.com/investors/news-events/press-releases/detail/129/standard-lithium-signs-key-agreement-to-advance-design-of

You're reading it correctly, Koch owned and operated. Looks like sli is finally making some headway!

About The ODP Corporation

The ODP Corporation (NASDAQ:ODP) is a leading provider of products and services through an integrated business-to-business (B2B) distribution platform and omnichannel presence, which includes world-class supply chain and distribution operations, dedicated sales professionals, a B2B digital procurement solution, online presence and a network of Office Depot and OfficeMax retail stores. Through its operating companies Office Depot, LLC; ODP Business Solutions, LLC; Veyer, LLC; and Varis, LLC, The ODP Corporation empowers every business, professional, and consumer to achieve more every day. For more information, visit theodpcorp.com.

I'll have to give my brain time to process what I am reading.

ODP Business Solutions

1,040 followers

1h • Edited • 1 hour ago

Following

Thank you USEPA for recognizing The ODP Corporation as a 2022 Safer Choice Partner of the Year! We are committed to designing, manufacturing, and using products with safer chemicals. #EPASaferChoice

https://bwnews.pr/3EnvTgx

https://www.linkedin.com/feed/update/urn:li:activity:6996494220937031680/

Am I reading this correctly?

Have you every seen that name or company?

awarded the contract to OPD LLC,

Yah go energy source! I'm a little let down SLI didn't release their continued demo data, it's rounding the corner of the "if it needs more adjusting" data. Good to see the Hydroxide Pilot though

I have not owned SLI for 3 to 4-years.

I get email updated every week.

ENERGYSOURCE MINERALS LLC, has started many private sister companies, and seems to be getting all the brine contracts in the USA.

From PEMIF, SLI, Compass minerals, and many more that I do not know about.

IBATF, has not announed any deals after 6-months of testing.

ENERGYSOURCE MINERALS LLC, is the one to watch.

https://www.esminerals.com/news

Sold that pump Friday. Enjoy

Standard Lithium

3,220 followers

1d • Edited • 1 day ago

We have successfully commissioned a first-of-its-kind direct LiCl to LiOH pilot plant. This aerial drone shot gives you an updated bird’s eye view of the facilities operating at our Lanxess South project. bit.ly/3DfZtT5 #lithium #engineering

Read comments.

https://www.linkedin.com/feed/update/urn:li:activity:6991737175578927104/

Standard Lithium Successfully Commissions First Direct Hydroxide Conversion Pilot Plant

https://investorshub.advfn.com/boards/read_msg.aspx?message_id=170299538

Similar Investments

We are noticing a considerable growth in lithium investment and lithium extraction development as we continue to electrify transportation and improve electric batteries.

For example, the US government set plans to invest $2.9 billion in the lithium battery supply chain in the US, which includes the development of domestic lithium production and extraction. In addition,

Standard Lithium, which specializes in lithium extraction testing, has received $100 million as an investment from Koch Industries Inc. and partnered with LANXESS Corporation to develop the first commercial lithium project in Arkansas. The lithium extraction process Standard Lithium uses is called LiSTR, which is similar to ILiAD in the benefits both have compared to previous lithium extraction methods.

https://solarpowerinvestor.com/iliad-lithium-extraction-platform-officially-partners-with-schlumberger-and-neolith-energy-a-game-changer-for-the-lithium-industry/

Are you seing what I am seeing?

SAN DIEGO, Aug. 16, 2021 /PRNewswire/ -- With one of the world's most experienced teams in brine processing at the helm, EnergySource Minerals (ES Minerals) is launching an entire new benchmark in sustainable lithium extraction and production.

This week, ES Minerals readies their first global deployment of their ILiAD platform, which offers clean, low-risk, small-footprint, near-market sources of lithium. The first extraction unit is being sent to South America and is set for arrival and deployment in Q4 2021.

https://www.prnewswire.com/news-releases/es-minerals-readies-iliad-platform-for-deployment-to-south-america-establishes-new-standard-for-sustainably-sourced-lithium-technology-for-the-ev-industry-301355339.html

Standard Lithium Signs Letter of Intent With Koch Minerals & Trading for Lithium Off-Take and Key Raw Material Procurement January 25, 2022

https://www.standardlithium.com/investors/news-events/press-releases/detail/110/standard-lithium-signs-letter-of-intent-with-koch-minerals

Make a post here at link below.

https://investorshub.advfn.com/LITHIUM-STOCKS-AND-CHARTS-38501

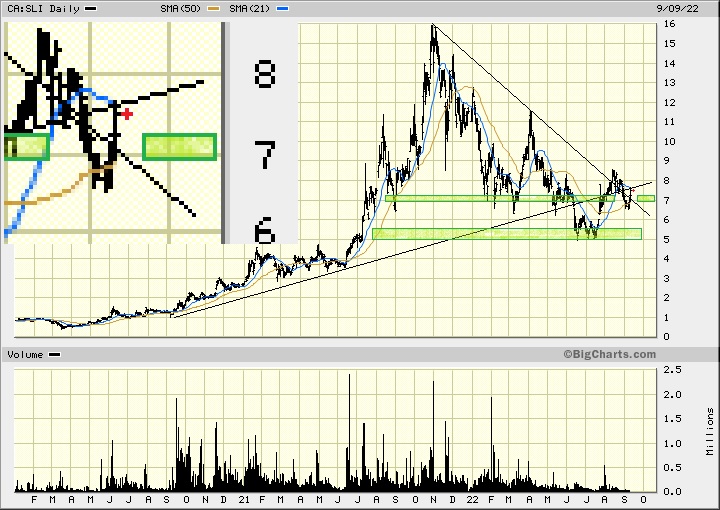

Up 6.2 to 5.82 - Nice call !

The upper green band here should have been drawn higher.

It would then match the AMEX above.

.Wild-looking long term view

https://bigcharts.marketwatch.com/advchart/frames/frames.asp?show=&insttype=&symb=sli&x=0&y=0&time=100&startdate=2%2F4%2F2006&enddate=5%2F19%2F2023&freq=1&compidx=aaaaa%3A0&comptemptext=&comp=none&ma=0&maval=9&uf=0&lf=1&lf2=0&lf3=0&type=2&style=320&size=3&timeFrameToggle=false&compareToToggle=false&indicatorsToggle=false&chartStyleToggle=false&state=11

Anyways, just kicking tires....

1/2 a good wknd there

Standard Lithium Ltd., Vancouver, Canada, (TSXV: SLL) (OTCQX: STLHF) (FRA: S5L), an innovative technology and lithium project development company, has successfully completed the conversion of its Arkansas-produced lithium chloride into 99.985% pure lithium carbonate using OEM technology. The work was completed by Veolia Water Technologies, at their facility in Plainfield, Illinois, United States, and demonstrates that the lithium chloride intermediate product produced by Standard Lithium’s industrial scale LiSTR Direct Lithium Extraction (“DLE”) plant in Arkansas can be converted into better-than battery quality lithium carbonate using established OEM carbonation technology.

Dual Track Program for Lithium Carbonate Conversion

As part of a continuous process of derisking the Arkansas Lithium Project, Standard Lithium opted to evaluate two different processes to convert the LiCl solution made by the Arkansas DLE plant into a battery-quality material. The first was using the Company’s own patent-pending SiFT technology as previously reported. The second, as reported here, was via conventional technology, widely used within the industry and performed by Veolia. Concentrated lithium chloride solution produced by Standard Lithium was sent to Veolia and was then converted to lithium carbonate using a conventional flowsheet. This involves additional concentration; chemical softening/purification; initial conversion to solid lithium carbonate; redissolution to a bicarbonate solution and final crystallisation, washing and drying of battery quality lithium carbonate. The material produced was of exceptionally high purity, as shown in Table 1 below where the composition is compared to typical specifications for battery-grade lithium carbonate compiled from a variety of commercial sources and producers’ specifications

https://batteryindustry.tech/standard-lithium-successfully-produces-99-985-purity-battery-quality-lithium-carbonate/

Indeed they started the downward trend fir SLI, but alas that trend is very close to turning back up again, these new lows are bargain prices and don’t be surprised if you see a 49% increase followed by a 20% increase very soon. This is real low hanging fruit and we are getting into this one asap Monday

Lock load time again so let’s make money

Lcbm125

Sli ~ most people won’t even see this huge spike coming soon real soon and when it dies it’s going to take off like you never could imagine. Be warned, it’s time to get in NOW and enjoy these next new highs that SLI s going to hit

Nice message and you are 100% correct and “right in the money”

Watch out fir some huge, I mean huge gains coming SLI way soon, really sooon

These b*stards know how to get in and buy low after spreading g negative lying press. But bigger better dats just around the corner ~ I mean close corner so lock b load guys

Episode 129: "Live from El Dorado" with Standard Lithium & Benchmark Mineral Intelligence

https://anchor.fm/globallithium/episodes/Episode-129-Live-from-El-Dorado-with-Standard-Lithium--Benchmark-Mineral-Intelligence-e1ea49f

https://seekingalpha.com/article/4484526-standard-lithium-short-report-a-big-ol-nothing-burger

Standard Lithium: Short Report A Big Ol' Nothing Burger

Feb. 04, 2022 3:07 PM ET

Standard Lithium Ltd. (SLI)ALB, BLILF, CYDVF, DJIFF, LISMF, LLKKF, LTHHF, LTHM, PEMIF8 Comments11 Likes

Summary

A short seller report was released full of speculation, misdirection, and general obmissions.

This might present an opportunity for long term lithium / electric car investors.

We go though the short seller report and point out flaws in the argument.

Arkansas

omersukrugoksu/iStock via Getty Images

As a writer you have to respect good writing. The writers at Hindenburg Research (an infamous short seller firm) are quite talented. Part of a good short piece is throwing a ton of spaghetti at the wall. In some cases short sellers do good work; in other cases (when the tips cease to flow) they pen hit pieces.

In this article we will review how much Hindenburg got right and how much it got wrong concerning Standard Lithium (SLI). Was the $100 million investment (at $7.42) by Koch simply blissful ignorance? Let's explore some of Hindenburg's claims.

Paint a Picture

Realize a writer can write in several tones. We see the tone of general doom and gloom all over this report and why not? They are short after all. A good writer can paint a picture that might not reflect reality accurately, i.e., spinning reality in a twisted manner by omitting facts. So let's focus and examine the twists and omissions in the article.

Nothing Burgers

The first gray tone in which Hindenburg tries to paint is stock promotion. (Another term for this is marketing.) This obviously carries a negative tone with investors, but in the mining industry stock marketing is the norm and is fine if disclosed by the promoter. Now of course marketing comes in various flavors: Paid interviews, research reports, and trade shows can all be considered marketing. Obviously, the first two are the ones to be cautious about. As long as the promoters disclose they are paid to write Bob Ross-like "happy little trees" pieces all is kosher, but the reader must be astute to recognize that any negative information will be ignored or glossed over in these paid reports. That is the danger in reports (be it a bullish or bearish report). Take them with a grain of salt. It is really not that much different from a short seller writing a misguided hit piece full of half truths and then admitting "Well, it is only my opinion, but I get paid if I bash it." In both cases your internal "Danger, Danger... Danger" needs to surface. The take away on marketing is to read, mull it over, and then do your own diligent research.

Breaking Down the Hindenburg Groups Misdirection

Any questionable article is going to try to direct your mind down a singular path hoping you concur with their conclusions. It is a bit more organic if you put 2+2 together in your mind rather than the author having to tell you the answer is 4. Let's look at some pathing the author is attempting.

1. Stock promotion aka Marketing. This is a reoccurring theme in the Hindenburg article and it is an easy win. Saying the word "promotion" comes with negative connotations. Yet (as previously stated) promotion is normal in the mining industry. Pull up ANY mining company and you will see some degree of promotion. Now how much promotion is too much is a topic of debate. Too much promotion and yes the stock price rockets up; but if the underlying company is not sound it then comes back to earth. Too little promotion and the company never gets the attention it needs and the share price does not rise. This limits the company's ability to tap the markets for capital in order to grow. The prudent thing to do is to examine peers and ask yourself "Is marketing out of line compared to peers?"

Breath in Your Fear - DLE

Now that Hindenburg has pushed the company as having spent some money on marketing, next up they attack the technology being used by calling DLE (Direct Lithium Extraction) into question.

Now on this one I got quite the kick out of the tone employed. DLE is everywhere in the industry. Many companies are using or testing DLE. One must also realize though that a part of the industry may not want DLE to be successful as they are extracting lithium via Brine (salt water) evaporation pools or they are crushing rocks to extract lithium.

Clay and DLE is the new kid on the block and some vested interests do not want the new kid stepping on their turf. The report tries to paint a glass half empty picture by saying the company received only one of three patents for its DLE tech and then continues on to say that DLE is old tech. Well, yes, it is but like engines in cars. Car engines are rather old (1807 in fact) but that does not mean you will not see new patents for engines. Another way of looking at this was Standard was successful in obtaining one patent for DLE, but frankly this point is a nothing burger presented by Hindenburg. Many companies are using DLE and I do not see any patent wars breaking out as, simply put, DLE is too common.

But Wait There's More!

To quote the late great Billy Mays "But wait there's more!" concerning DLE. Riddle me this. If DLE in general was so unsuccessful why would Bill Gates, Jeff Bezos invest in DLE technology via Liliac Solutions? Why are many players in the industry looking to DLE? Companies such as:

Cypress Development (OTCQB:CYDVF) in Nevada has teamed up with none other than the famous Craig Brown of Chemionex (whom Hindenburg noted but failed to research.) If Craig Brown were so inexperienced and the process did not work it's a small wonder that Cypress Development went with it and paid Craig Brown $350,000 CAN dollars and 1 million shares in Cypress (Currently $1.44 USD).

Pure Energy (OTCQB:PEMIF) - Has teamed up with Schlumberger for DLE in Clayton Valley Nevada. Note: Everyone in Clayton Valley, except Albemarle (ALB) has gone the DLE route to my knowledge due to extreme lack of water and ALB is eying the tech (more on this later).

HeliosX Lithium (OTCQB:DJIFF) - Formerly known as Dajin Lithium. They have teamed up with Liliac solutions for one of its Nevada properties.

Lake Resources (OTCQB:LLKKF) - Has teamed up with Liliac.

Vulcan Energy in Europe is going down the DLE route. Livent (LTHM) is using DLE and producing revenue. Lithium South (OTCQB:LISMF) is exploring DLE technology and the list goes on and on.

Additional information about DLE and companies using it can be found via Matt Bolshen's article on the subject. It has some informative graphics in it. Moving on.

Cherry Picking Quotes

I also find it interesting when an author cherry picks a quote from a big name but provides no context nor the full picture. Case in point when Hindenburg quotes Eric Norris but skews the full picture by omitting quotes that go against the picture they are trying to paint. Hindenburg paints DLE in a negative light via:

"It's more capital intensive and actually consumes a lot more water and energy" - Eric Norris, President of Lithium Division, Albemarle Corporation

Yet in the same article we see Eric Norris of Albemarle talking about Arkansas DLE in a somewhat positive light via:

"Norris, Albemarle’s president for Lithium, said the company continues to look at its Magnolia-area chemical plants “as being a spot where we could process lithium in DLEs. There is potential technology for that.”

(Source: Magnoliareport.com via the Hindenburg Report)

You the reader are not being presented with the entire truth but simply one misdirected angle. So now it is time to paint my own picture for you and show you that the big boys are indeed looking at DLE.

Albemarle and DLE Tech

Let's see if Albemarle is playing coy with us. Looking at the September 2021 Investor Day presentation, we see that 35% of sales are from bromine. Keep this in mind as we go to the next slide.

Bromine, Hidenburg short seller attack, Lithium, Standard Lithium

Overview of ALB Revenue (Albemarle)

(Source: Albemarle)

Now realize that only two locations produce bromine for Albemarle (one of which is right next door to where Standard Lithium is operating). Looking at slide #26 of the ALB presentation, we can guess that the Arkansas location brings in 25% of bromine 2021 estimated capacity, if we assign them 175 kT of capacity.

Bromine, Smackover, Lithium Smackover, Bromine extraction, Arkansas

Bromine Capacity (Albemarle)

(Source: Albemarle Slide #26)

Do you think ALB is going to ignore the capability to tap that market much like Standard Lithium is currently endeavoring to do? I think not. Now let's do a bit of guesswork. Given all the locations ALB has world wide, it does not hurt them to expand tried and true processes (like lithium rock extraction or brine), while DLE technology is proven and matures. It hurts them nothing to watch Standard Lithium to see if the technology works, and (if so) mimic it for their bromine operation.

Now realize that ALB has some DLE plans even though they might not advertise it constantly. We can theorize this via "Albemarle to double capacity at Silver Peak lithium brine operation". Note the use of the word "clay" in the below snippet. Clay = DLE in many cases. Per the article:

"Albemarle Corp has confirmed it will expand capacity at its lithium production facility in Silver Peak, Nevada, USA, and begin a program to evaluate clays and other available Nevada resources for commercial production of lithium.

Beginning in 2021, the company plans to invest $30-$50 million to double the current production at the Nevada site by 2025, making full use of its brine water rights. Additionally, the company plans to commence exploration of clay and evaluate technology that could accelerate the viability of lithium production from clay resources in the region this year."

Our good friend Eric Norris, Albemarle President, (whom Hindenburg cherry picked earlier) pops up via:

Eric Norris, Albemarle President, Lithium, said: “As a leader in the lithium industry, our priority is to optimize our world-class resources and production. This includes Silver Peak, a site uniquely positioned as the only lithium-producing resource in the United States.

“This investment in domestic capacity shows that we are committed to looking at the many ways in which Silver Peak can provide domestic support for the growing electric vehicle market.”

When I read "many ways" I translate that as clay to support domestic lithium, and if it is clay that means DLE technology. The majority of lithium clay resource I've seen uses some form or mutation of DLE tech, but wait Hindenburg said DLE is pie in the sky right... right? (Insert Anakin meme). Moving on.

Next Fear Point - Costs

The next avenue of attack is hitting the Standard Lithium project via unnamed "sources". Why not name them so we can see the credentials? Oh well. The conjecture of the unnamed "sources" is costs will be "stunningly expensive". Let's see how expensive the costs will actually be via 3rd party verified NI 43-101 Preliminary Economic Assessment Technical Report. This is a document you will often see via Canadian based mining companies. Consider it a required standard. Can it be off a bit? Sure. Remember, it is preliminary (after all), but typically they are somewhat close to reality (give or take) since it is created by 3rd parties and they have to certify the report. In this case, Worley created the 43-101. You can download the 43-101 and read it yourself rather than go out and party on a Saturday night.

Per the 43-101, we can see

All-in operating costs, including all direct and indirect costs, reagent, sustaining capital, insurance and mine-closure costs of US$4,319 per tonne of lithium carbonate (4)"[4] Includes all operating expenditures, including sustaining capital and allowance for mine closure.

So the estimate is $4,319 costs per ton and selling prices of lithium were modeled at $13,550. Obviously these modeled prices are a bit low now days. Granted, it is a bit hard to nail down what average selling prices are with long term agreements in place by various large lithium sellers (ALB, SQM, etc.) and such, but take the below chart. Subtract a large imaginary number and you are still much higher than the $13,550 SLI was projecting back in the day as prices are approaching $60,000. Again, this does not always mean a company will get $60,000 a ton but you can see that $13,550 is on the low side of the equation.

Lithium, lithium prices, white gold,

Lithium Prices 2017 - Feb 2022 (Daily Metal Price)

(Source: Daily Metal Price)

If you take anything away from this article it should be this: Always sit down and read the entire 43-101. You will not initially understand all of it but the more of them you read the more you will learn. The 43-101 is chock full of valuable data and plans. It is THE blueprint for a project. If you are not reading them then you are at a severe disadvantage in this game of financial Mortal Kombat.

More Nothing Burger Than Nothing

So far, we have covered bogus marketing claims of Hindenburg, then the negligent DLE side of the equation along with unconfirmed cost fears. The next stage of attack is to try to tie the CEO Robert Mintak to various companies and shady actions. Oddly they fail to mention Mr. Mintak was recognized as CEO of the top mining companies on the TSXV50 in both 2016 & 2018.

Here is the thing to note while reading this: Did the CEO commit these actions and then somehow get listed on the New York stock exchange and then somehow magically Koch never bothered to look into management while plopping down $100 million, technical support, and an LOI offtake agreement? Seems unlikely, but what the heck. Let's see what Hindenburg says as it paints a picture to profit at the expense of other investors.

Space Balls

Anyone remember the comedy "Space Balls"? Reading over the Hindenburg report I feel like I'm watching Space Balls via some of the far fetched connections they are grasping at.

Dark Helmet: I am your father’s brother’s nephew’s cousin’s former roommate. Lone Star: So what does that make us? Dark Helmet: Absolutely nothing.

(Source: Space Balls)

Point #1 - Hindenburg says CEO Mintak worked for an IR firm back in 2005 and now (gasp) his former coworker Jeremy Poirier in 2022, at a totally different company (Bearing Lithium), is being investigated by the B.C. Securities Commission for failure to disclose promotional material.

It should be noted that Hindenburg once again displays its apparent lack of knowledge by calling Bearing Lithium (OTCQB:BLILF) "another failed lithium project". I suppose they do not realize that Bearing owns 17.14% of the Maricunga lithium project. The rest of the project is owned by Lithium Power International (OTCPK:LTHHF) at 55.55% and Minera Salar Blanceo at 31.31% (but enough digressions). To wrap up every single error on Hindenburg's part would require a small treatise.

Point #2 - Hindenburg paints:

"Many of Mintak’s ventures, often involving Jeremy Poirier, saw meteoric rises in share price on the back of paid stock promotion, only to collapse just as quickly during major sell-offs. As we will demonstrate, several also came under regulatory scrutiny."

I would not personally call a gold company that Mr. Mintak is a director at a "Mintak Venture" and I do not see any promotion going on at the surface. If we did, we would see a meteoric rise in share price and a collapse. This chart does not meet that definition for ticker GIDMF. All we see is a small penny stock that has drifted down and one might surmise that is why the CEO stepped down.

stock chart, GIDMF, gold, white gold,

Golden Independence Mining Corp (Yahoo Finance)

(Source: Yahoo Finance)

Frankly, the Hindenburg nothing burgers go on and on. I could continue to break this down but frankly it is a waste of my time and your time to continue down this nothing burger hole concerning the CEO.

Land Deals

While Hindenburg goes down a land rabbit hole the real question here is simply this: Does Standard Lithium hold rights to the land claims in Arkansas and to a lesser importance in California? The answer is yes.

Reverse Merger

Why Hindenburg even included this one is a mystery. This one is easy. Shell companies that have a ticker symbol have value. This is Finance 101. Much easier to do a reverse merger than start afresh. Now it is time to shift the article back to reality and look at what the company is actually doing.

Financials Misconstrued

It is not hard to misconstrue financial statements. Now I will not venture if this was a deliberate act or not on the part of Hindenburg. I will leave that to the readers to decide. However per Standard Lithium we can see they made a rather obvious goof up when looking at the math. Per Standard Lithium:

It is claimed in the report that only approximately CDN $ 1.7 mm has been spent on research and development. This figure is incorrect and does not include either the CDN $ 29,409,930 spent on the various pilot and demonstration plants that has been capitalized, or the CDN $ 6,932,598 spent on operating expenses at our pilot and demonstration plant, both of which constitute our ongoing R&D program, and are disclosed as of September 30, 2021 in the Company’s most recent financial statement and the end of year statement as at June 30, 2021.

(Source: Standard Lithium)

$100 Million Dollars Invested by Koch

Now let's get to the good part. I'm talking about the part where you can tell Hindenburg just threw in the towel and almost quipped "missed red flags and failed in its due diligence in its haste to deploy capital." and yet they do not tell us what red flags they missed or what due diligence they failed to carry out. The translation is they do not know and are unable to counter this point.

$100 million was injected into the company via Koch via a direct investment at $7.42 USD a share. Does anyone honestly think a company is going to invest one hundred million dollars without having a thorough understanding of every nut and bolt at a company?

Now the first response the short sellers will offer is to look at project X that Koch put money into and it went down. Yes, this happens to any investor or investing firm. I've had my fair share of companies that I entered too early and lost money (SSD hard drives come to mind ten years ago or GPGPU on graphics cards back in 2006). Point is, I'll bet that the boys at Koch kicked the tires quite a bit before investing $100 million and this does not look like their first foray into the lithium sector.

Koch invests $100 million in Li-Cycle

Koch forms a 50/50 partnership for a battery company w/ FREYR.

Koch invests in charging solutions.

And Koch stands by the due diligence and Standard Lithium via:

Koch responded with this statement: “As with all of our investments, Koch has conducted extensive due diligence and found Standard Lithium’s technology a promising bright spot on the path towards lithium production here in the U.S. We remain excited to continue fostering innovation and growing the battery value chain across the Koch enterprise.”

(Source: Marketwatch.com)

Conclusion & Musings

Short sellers have a role in the market and that is to shed light upon the darkness. Short sellers can uncover financial games and trickery. However one must question the motivations of some short sellers at times when presented with facts. This is one such case in my opinion. Could I be incorrect? Absolutely and that is why you need to trust but verify. Do your own research, read those 43-101 reports and question them too. This way you are educated and when Mr. Market goes loco you will have the knowledge to either roll the dice on options (be it long or short) or even step out for the day. My takeaway is yesterdays sell off is an unjustified reaction to a bogus nothing burger. With time the stock should recover as investors realize this. Hence Mr. Market might be presenting us with an opportunity if our assessment is correct.

This article was written by

Austin Craig profile picture

Austin Craig

6.21K Followers

Disclosure: I/we have a beneficial long position in the shares of SLI, LAC, CYDVF, DJIFF, LITOF either through stock ownership, options, or other derivatives. I wrote this article myself, and it expresses my own opinions. I am not receiving compensation for it (other than from Seeking Alpha). I have no business relationship with any company whose stock is mentioned in this article.

Additional disclosure: We have also bought July $7.50 calls in SLI.

We have sold $7.50 and $5 April puts.

We own LPI (lithium power international on the ASX).

We own Lithium South (LISMF)

We own Dajin on the Canadian exchange under HeliosX (ticker HX).

We own long calls in LAC and have sold covered calls as well.

8 Comments

Like This Article

Save

Share

Print

Comment

Recommended For You

Comments (11)

Sort byNewest

J

Jpsychc

Today, 3:42 PM

Comments (1)

|

Why do you claim they “received” one of 3 patents when they have zero approved. Two rejected and 1 is not reviewed yet.

Like

Austin Craig profile picture

Austin Craig

Today, 3:45 PM

Contributor

Premium

Marketplace

Comments (8.1K)

|

@Jpsychc It is pending but yes, I should alter that as it could be put in a better way. Minor revision pending. Good catch.

patents.google.com/...

Like

N

nottheboss1

Today, 3:34 PM

Marketplace

Comments (432)

|

Thanks, again, Austin. I didn’t need to wait on your article. Your “lol” comment yesterday was enough for me, and it came in time for me to take action.

Like

Austin Craig profile picture

Austin Craig

Today, 3:55 PM

Contributor

Premium

Marketplace

Comments (8.1K)

|

@nottheboss1 You might be surprised how many people flipped the script on that comment. LOL

Like

N

nottheboss1

Today, 3:58 PM

Marketplace

Comments (432)

|

@Austin Craig - Maybe, they’re like me, and the only thing they wanted to know is “what does Austin think?”

Like

S

Splinter007

Today, 3:30 PM

Premium

Comments (16)

|

Mic Drop

Like

S

ShortySk8n

Today, 3:19 PM

Premium

Comments (187)

|

I haven't even read this article yet. Thank you so much.

OK, Now that I've read your article. I'm even more thankful. But confused about one thing. These two statements /quotes from your article seem to contradict each other?

1) Note: Everyone in Clayton Valley, except Albemarle (ALB) has gone the DLE route to my knowledge due to extreme lack of water.

2)Hindenburg paints DLE in a negative light via:

"It's more capital intensive and actually consumes a lot more water and energy" - Eric Norris, President of Lithium Division, Albemarle Corporation.

The first says everyone but ALB is using DLE because of the lack of water in Clayton NV. The second says DLE uses more water. So which is it?

Like

Austin Craig profile picture

Austin Craig

Today, 3:56 PM

Contributor

Premium

Marketplace

Comments (8.1K)

|

@ShortySk8n I'm sure to get a few things wrong. Spellling errors, minor article flow problems, pretty much any article an author is going to screw something up.

This was a rather quick article due to popular demand. Typically I like to spend about 2 weeks crafting something.

Today, 3:18 PM

Premium

Comments (73)

|

Austin, Thank you for putting out a report on refuting the Short sellers claims…Great read

Today, 3:17 PM

Comments (165)

|

And , of course , you see it’s up 16% today. Way to shed some light on the dark side of short selling!

Like

R

Rmc7744

Today, 3:16 PM

Comments (165)

SLI is crashing severely today. This is apparently because of a report from Hindenburg Research that made scathing allegations against the management of Standard Lithium. You never really know who to believe. Sometimes the authors of highly derogatory information have huge financial interests themselves which may be motivating them to issue such reports. So you really have to dig to find out what the truth really is and never take anything for granted.

Premarket seems happy, up 10%

KEY REVERSAL WEEK ALERT! Bottom at 5.50 is in and will not be seen again imo

|

Followers

|

42

|

Posters

|

|

|

Posts (Today)

|

0

|

Posts (Total)

|

573

|

|

Created

|

06/29/17

|

Type

|

Free

|

| Moderators | |||

Standard Lithium chose south Arkansas as a key development target due to its very large resource potential, with a well-studied and documented brine deposit. Combine this with a pro-business environment, a region with more than five decades for commercial brine production, the associated infrastructure; pipelines, well fields, low-cost power, road, rail and a highly skilled work force. This makes Standard Lithium’s south Arkansas project the perfect location for a modern lithium chemical company.

The Company’s flagship 150,000 acre, 3.14 Million Tonne Lithium Carbonate Equivalent (“LCE”) resource Joint Venture** “Lanxess Project” is located minutes away from the city of El Dorado, Arkansas.

El Dorado is headquarters of the Arkansas Oil and Gas Commission as well as Murphy Oil, Murphy USA, Deltic Timber Corporation and a Delek US oil refinery. The city has a nationally-recognized downtown arts district, the Murphy Arts District (MAD); a community college, South Arkansas Community College (South Ark); and a multi-cultural arts center, South Arkansas Arts Center (SAAC). El Dorado is the population, cultural and business center of south-central Arkansas.

El Dorado is located approximately 120 miles (190 km) from the state capital of Little Rock. The city was the heart of the 1920s Arkansas oil boom. During World War II, it became a center for the U.S. chemical industry, which still plays a key part in the local economy, as do oil and timber.

The region is home to North America’s largest brine production and processing facilities.

When oil was discovered in south Arkansas in 1921, oil field brines were considered a worthless by-product of oil producers who had problems disposing of the brine. Then, chemists from the Arkansas Geological Commission (now the Arkansas Geological Survey) discovered that the Smackover Formation brines had high bromine content—seventy times greater than that of ocean water. Bromine production followed oil production in Union County in 1957 and has continued ever since. Bromine production in Union and Columbia counties contributes significantly to the local and state economy and employs over 1,000 people. Great Lakes Chemical Corporation built the world’s largest bromine plant in south Arkansas in 1961. Great Lakes Chemical Corporation merged with Crompton Corporation in 2005 to create Chemtura Corporation. Chemtura Corporation was acquired by global specialty chemical company Lanxess AG in 2017. Lanxess operates three brine processing plants in south Arkansas.

TETRA Technologies operates a processing plant in the area, Albemarle Corporation (formerly Ethyl Corporation) operates two bromine processing plants in Magnolia (Columbia County) Arkansas.

Lanxess operations in south Arkansas cover 150,000 acres that includes10,000 brine leases. Lanxess extracts brine from their wells located throughout the area, and the brine is transported through a network of 250 miles of pipelines to three plants where the brine is processed for bromine recovery with the tail brine then re-injected to the aquifer. The three bromine extraction plants currently employ approximately 500 people, have been in production for nearly five decades, and produce roughly 5.3 billion gallons of brine annually.

A Preliminary Economic Assessment prepared by Advisian, a consulting arm of Worley Parsons, released June 18, 2019 considers the production of battery-quality lithium carbonate through a phased build-out to a total 20,900 tonnes per annum (tpa) from the contemplated joint venture with Lanxess AG at their three-operating bromine-processing plants.

Notes:

All model outputs are expressed on a 100% project ownership basis**

[1] Total production, using existing brine supply rates at the completion of Phase 3

[2] Plant operation commences upon completion of Phase 1

[3] Includes 25% contingency of both direct and indirect capital costs

[4] Includes all operating expenditures, including sustaining capital and allowance for mine closure

[5] Selling prices ranging between US$10,840-16,260/tonne were modeled as part of sensitivity analysis

** 70/30 JV in favor of Lanxess AG with an option for Standard Lithium to achieve 40% subject to attaining certain milestones

*** See news release Nov 12, 2018 - Subject to proof of concept & positive feasibility study

Top: Map of Lanxess Project South Central Arkansas, Bottom: Lanxess Southern Brine Plant

Top: Map of Lanxess Project South Central Arkansas, Bottom: Lanxess Southern Brine PlantStandard Lithium has an option agreement with NYSE listed TETRA Technologies Inc. to acquire the rights to conduct exploration, production and lithium extraction activities on 27,262 acres of brine leases located approximately 40km west of the Lanxess project. This is in an area where the Smackover Formation is known to be highly productive. The TETRA Project lithium brine Inferred Resource, as reported, is contained within the Upper and Middle facies of the Smackover Formation, a Late Jurassic oolitic limestone aquifer system that underlies the entire property. This brine resource is in an area where there is localized oil and gas production, and brine is produced as a waste byproduct of hydrocarbon extraction. The data used to estimate and model the resource was gathered from active and abandoned oil and gas production wells on or adjacent to the property.

The resource underlies a total of 807 separate brine leases and eight brine mineral deeds which form a patchwork across Columbia and

Lafayette Counties in southwestern Arkansas. The property consists of 11,033 net hectares (27,262 net acres) leased by TETRA, and the resource estimate was only modeled for that footprint.

Standard Lithium has agreements with regional independent oil and gas producers with open, unused Smackover Formation wells in and immediately adjacent to the new lease area to gather new, high-quality lithium brine samples from the key brine production zones.

Notes:

[1] Mineral resources are not mineral reserves and do not have demonstrated economic viability. There is no guarantee that all or any part of the mineral resource will be converted into a mineral reserve.

[2] Numbers may not add up due to rounding.

[3] The resource estimate was completed and reported using a cut-off of 50 mg/L lithium.

[4] The resource estimate was developed and classified in accordance with guidelines established by the Canadian Institute of Mining and Metallurgy. The associated Technical Report was completed in accordance with the Canadian Securities Administration’s National Instrument 43-101 and all associated documents and amendments. As per these guidelines, the resource was estimated in terms of metallic (or elemental) lithium.

[5] In order to describe the resource in terms of ‘industry standard’ lithium carbonate equivalent, a conversion factor of 5.323 was used to convert elemental lithium to LCE

In the conventional process for lithium extraction from brine, the lithium-rich salt water is pumped to the surface and deposited into a series of massive ponds that occupy many thousands of acres where passive solar evaporation occurs. This process can take anywhere from eight months to greater than a year. After the water has evaporated, and other minerals have been precipitated out through the addition of chemical reagents, the remaining lithium enriched solution is transferred to a plant where additional unwanted elements are removed from the solution. It is then chemically treated to create the final product of lithium carbonate, or further processed to lithium hydroxide. This entire process involves pumping millions of gallons of brine per day to the surface in some if the driest and most fragile eco-systems, the process is also very inefficient with lithium recoveries of roughly 50%, leaving much of the precious material unharvested. The removal of massive volumes of brine can also impact nearby freshwater aquifers exacerbating existing water shortages, and the evaporation process leaves huge salt tailings piles.

A new, modern approach to how we extract and process critical minerals like lithium is overdue.

For the company’s south Arkansas projects, Standard Lithium has developed a proprietary process called “LiSTR” that uses a solid ceramic adsorbent material with a crystal lattice that is capable of selectively pulling lithium ions from the “tail brine” or waste brine after it has gone through the bromine-extraction step. The ceramic adsorbent materials are mounted in stirred-tank reactors that contain the tail brine. In the second step, the adsorbent releases the lithium for recovery.

The Li-extraction process (diagram) takes advantage of the fact that the brine leaves the bromine process heated to approximately 70°C. This means that no additional energy is required, and the reaction kinetics for the adsorption are suitable. The process can reduce the time required for Li extraction from months (with the evaporation ponds) to hours and is capable of producing a high-purity LiCl solution for further processing in the battery industry. The Li-extraction operating as a “mini-pilot” project has run continuously for a number of weeks utilizing raw tail brine from the project and a larger modular industrial scale Demonstration Plant is expected to be deployed at Lanxess’ southern processing plant in the fourth quarter 2019.

Top: Simplified Flowsheet, Bottom: LiSTR Demonstration Plant at Zeton fabrication facility May 2019

Top: Simplified Flowsheet, Bottom: LiSTR Demonstration Plant at Zeton fabrication facility May 2019

The Smackover Formation is an extensive porous and permeable limestone aquifer that hosts huge volumes of mineral-rich brines, as well as hydrocarbons. The Smackover Formation brines are one of the largest source of bromine in the world, but the brine also contains significantly elevated levels of lithium – typically ranging from 150 to 500 mg/L. Several dozen wells pump out brine and send it via pipeline networks to process plants. Once minerals have been extracted the waste brine (tail brine) is re-injected back into the Smackover Formation aquifer.

Average annual brine production between 2010 and 2016 is estimated at 42.6 million m3 (9.4 Billion US Gallons) from Arkansas Oil and Gas Commission data. Presently, bromine is recovered from brines in Columbia and Union Counties mainly by Lanxess and Albemarle Corporation.

Core samples from Smackover Formation visually demonstrates well defined high porosity. High Porosity is present throughout the project area. The Smackover Formation can produce large volumes of brine and allows for large volumes to be reinjected.

Highly porous aquifer stores & moves brine easily

Highly porous aquifer stores & moves brine easilySouthern Arkansas is a business-friendly jurisdiction with a decades long history of operating chemical, oil & gas, forestry, and manufacturing industries. The region’s hydrogeology is well-documented, the large existing commercial brine production brings a significant infrastructure investment along with access to low-cost power, water, and a skilled workforce.

Standard Lithium is in a unique position to leverage the existing brine production to fast-track the projects commercial development with the aim of building the first new U.S. lithium project in over five decades.

| Volume | |

| Day Range: | |

| Bid Price | |

| Ask Price | |

| Last Trade Time: |