Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.

Greetings, Great new tech happenings. I wonder if Frankie and Harry will post on face that they have a LOU from ETS concerning the Mark-V engine soon to be coupled to the Joule Hive generating 3275 degrees F. I recall the video of Harry proving the engine worked. in the alley with a pitcher of deionized water pouring by hand into a funnel with a clear tube into the mark-5 and the piston went around. I bet that video and frankie's deep understanding would surely convince those MIT prof.'s now outside the U and in ETS a new start-up. OLD tech=firebricks. LOL who knew 1 world 1 engine. Joule Hive. peace. PS. and no I'm not paid by BIG oil, or utilities, or Briggs & Stratton. or anyone. in fact i'm unemployed. Have been for 15 years now. gettin' old. ha ha GLTA.

Greetings Ya' All, I just popped in for a good laugh, and as always I was NOT disappointed. Frankie and blame Obama....what a riot. After all the LIES over 17 years and over $60 Million wasted. harry is still " Just gettin' started". lol. I recall he was interviewed and claimed to have a " Family of market ready " Products". that was so many years past. WHE is now everywhere. LOL. and that LSR. lol. Never finished that giant custom yauht over at schoell marine. so many hot projects in the fire...they musta burnt up after Obama hired agents to spy and post here. maybe I could be 1. Where's my check Obama?? LOL. Google luck to all here at biggest scam site everville. regards kids.

Hi Bobby. This is Tom, I have no idea why IH changed my name. Hope you've been doing well. Honestly, the Liquid Piston engine doesn't excite me. For all the talk about superiority over a Wankel, it has the same weakness that has doomed Wankels over the years -- the seals. A lot of time and money has been put into rotary engine seals over the years and the solutions still don't compare to piston rings in typical engines. The rotor is also fairly complex to manufacture, and it needs very precise tolerances to function properly. It's a lot easier to hone a cylinder than to produce complicated housings and rotors to the same tolerances. Then, I am bothered by the entire issue of lubrication. It isn't as though we have oil jets or splash lubrication up the cylinder bores playing on the walls. That oil spray also cools off the piston to prevent burnout. They claim that they can lubricate the seals without excess oil consumption, but we are talking about a line seal versus the restriction provided by a piston in a cylinder. Oil in the combustion chamber is going to make it very, very hard to meet emission regulations. Then there's the issue of thermal management, the surface area to volume ratio looks relatively unfavorable...I'd expect the engine will lose overall efficiency due to this. Finally, like so many other 'clever' mechanical arrangments, the force is hardly tangential to the rotor -- you get far better mechanical advantage with a crankshaft and connecting rod. I'd guess that you need to spin this thing at really high rpm to generate the same power as a piston engine -- which introduces friction problems that reduce life expectancy and fuel efficiency.

Hey Buddy!

Check out the news on QSAM from 2/7/24. What are you thoughts on it? Did Chris Nelson do right by the shareholders??

-Chuck

Proof they are totally delusional.. They really think the government paid people to post negative comments.. people questioned the engineering and physics behind the "Schoell cycle" and because they couldn't actually prove it worked with a prototype that outputs the claims they made, their cognitive dissonance makes them believe it was a government conspiracy out to get them.

The facts remain the same: No Cyclone engine ever ran for a period of longer than 1 second outputting the HP/TQ that Cyclone claimed it would make.

17 years in and they haven't got past the proof of concept phase, let alone anywhere near having a product that would be produced in a production setting.

As a FB user mentioned "Physics wins in the end".. yes it does.. it proved the Cyclone engine is a failure!

-Chuck

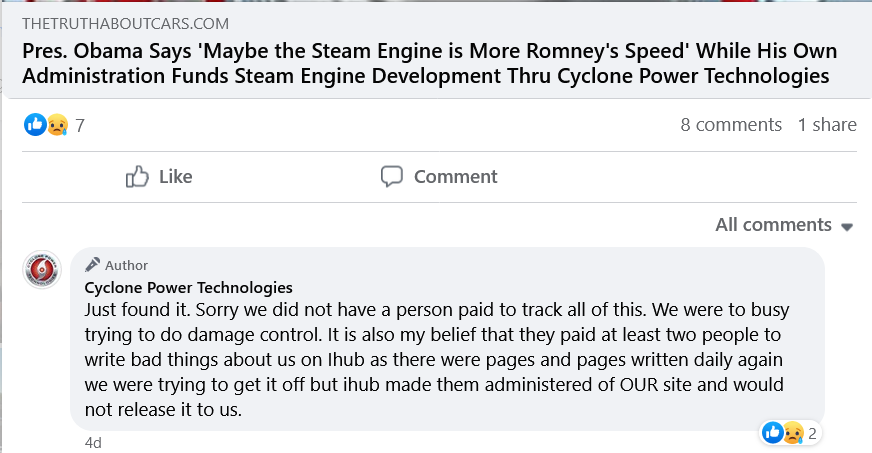

New year and Frankie's even nuttier. From Facebook:

Yep, it's all Obama's fault. Remember the jokes from 10 years ago? "It rained today. I blame Obama." Cyclone, after squandering at least $25 million of investors' money on their "market-ready" steam engines and not being able to even run a go-kart around a parking lot, is now blaming Obama.

(And Frankie -- before you start claiming that $25 million was paper derivative losses, remember that those were an additional $30 million.)

Even though that genset for the Army was delivered years behind schedule and didn't work any better than any of their other engines (e.g., if it was so great, why didn't Cyclone ever build another copy to show people one of their engines actually producing any power?), and the Army declined to award them a new, bigger contract to produce more useless junk, it was all Obama's fault.

And all their other announcements of all those other Mark 2 through Mark 10 engines going into production soon and it never happening? Yep, Obama's fault. Every last one of them. Even before Obama was elected.

By the way, here's a link to the article from February 2013 about their land speed car #2 ambitions: https://archive.org/details/Racecar_Engineering_2013_02/page/n19/mode/1up Here are some quotes:

"drive the car up to 200 mph in the first quarter of 2013"

"The plan is to hit 200 mph, before prepping the car for a 250 mph run at Bonneville salt flats in the summer, "

"The new engine will then be fitted with a target of 400 mph"

"and intends to extend that to 400 mph by the end of 2013."

'It just takes time to get it there, The LSR is to prove that we have a viable product. People have to see it, We have generators running, but to see something like this has excitement to it. We also have a boat we are going to run to show the viability of the product. It is amazing to us, we have been at it for a few years, and every time we show it people haven't heard about it. We have grown making generators and products for other applications;

Greetings, this is for the engine smart guys here ( I'm not qualified) but for Buddy, Tom. and Chuck....I was reading this and thought of you'all. enjoy and PEACE....n case engine aficionados think they’ve already seen this one before – look again.

LiquidPiston is turning therotary, the previous attempt at a smaller, lighter, more fuel efficient engine, inside-out. Instead of a triangular rotor in a “peanut” shaped housing, LiquidPiston’s engines have a peanut-shaped rotor with tri-lobed housing for better fuel-air mixing and combustion. 🤨

Hi Chuck. Thanks for keeping the Con watch fires burning. And the new location for cypw. LOL. I'll bet ol' doofus is still telling prospective Marks " I'm just gettin' started". LOL. Cons use the same lines over and over." One world one imaginary magic water engine"! Well I heard frankie and doofus modified an old row boat and frankie is gonna finally go for that Heavily advertised WSR. The tens of MILLIONS of other people's money spent on the other 3 engineless boats were all part of harri'z Master Plan for the whole WORLD. well thanks ya'all was fun. PEACE

Hello board!!??Like to pop in twice a year. See whats new. LOL Nuttin'

Current Picture (May 2023)

It's pretty sad when you have to dismantle the non-working prototype display to make a sign for your almost defunct company.

Some of you might recognize it.... previously it was attached to a fake engine made of wood installed in a truck frame.

I wonder how the people who's names are listed on that trailer feel about how their donations towards the Land Speed Record were used.

Everything you need to know about Cyclone is shown in this picture..

The loading dock visually describes the current company status..... UNDER WATER

Comical how they keep using "One Engine", but in 16+ years of taking investors money.... they HAVE NOT PRODUCED ONE SINGLE ENGINE

4 months after their latest open house that only drew 1 single investor... no news...

That was supposed to be the rebirth... hahahahahahaha seems more like another nail in the coffin.. this scam is DEAD

I see Tom, Chuck, and Buddy are still helping with reality here. I will just add I've been following CYPW cyclone harry and fruge for 16 years. SSDD. Cons liars and cheats. Period. I'm a retired stock trader HFT. I'm a literal expert in stock investing. This has always been a scam. Harry Schoell on radio interview proclaimed " Cyclone has a family of Market ready Products". We are setting up our global distribution, and will be at market in 6 months. That was in 2004. PERIOD! The posters I mentioned know far more than I about engines and tech. As I said I've made a living in investing in stocks. My HFT designation is from IRS not me. My last working year I personally traded volume of $71 Million USD. I don't clown around when it comes to investing. Harry and fruge are crooks. Cons. Scam artists. 16 years and this is exactly the same CON. these creeps are so crooked during the GEM deal the SEC had to block harry and fruge from diluting all shares and assets in Cayman Islands financings. CDC's selling DEBT. that is the Cyclone business model. period. regards. Bobby

HA HA HA......I can't believe it. This scam is like Jamie Lee Curtis horror series. Never die scam. LOL I sure hope james jones and ides of april he he is still a pumper. LOL. What a joke. TEXAS. ha ha.

The biggest problem with all this, and there are a huge number of problems, is that they haven't taken their dire circumstances as a sign that they should 'fess up to the fact that the original design was always problematic and that something drastic is necessary to get things on track. (Spider bearings, lack of control system, far too little condenser surface area, water lubrication, and so on, and so on, and so on...)

Cyclone is still standing pat with the old "You've seen it run in videos" line -- which is exactly the problem. The only thing that we have seen is a shaft turning, and often not that impressively. The car is still stationary. The boat is still dormant. We have yet to see a pump throwing a huge stream of water, a generator powering up a set of spotlights or any other evidence that the machine can perform large amounts of useful work. Heck, they moved from Florida to Texas, so having the thing run an A/C unit would be good -- although maybe a bit hard to verify on video.

If insanity is doing the same thing and expecting different results, then Cyclone is looking for insane investors.

Besides, does anyone think that you can trust a company that can't even put the right address on its website? It goes without saying that the devil is in the details -- if a mere website change is out of grasp, is it realistic to expect that they can engineer a power plant, assemble, test and place it into production?

That was the single sucker who showed up for the open house....

Nothing to see but 10+ year old non-working models...

That is not an R&D or production facility.. I wouldn't even call it a hobby shop! It's a storage facility... Are they going to assembly and test engines on those plastic folding tables??

Who was it that said "Delusions-R-US"???? He was right on the money with this one...

-Chuck

And the scam begins again...

On Facebook:

Cyclone Power Technologies

October 13 ·

Cyclone is pleased to announce the Reboot of Cyclone Power Technologies, Inc. with an Open House at our new facility and an on-line virtual tour on Cyclone Power’s Facebook page.

Our founder, Harry Schoell, and two of our long time investors bought the building together for the sole purpose of completing the research, development, and demonstration of the latest refinements and applications of Cyclone Power’s Advanced Rankine Cycle Engine. Numerous Cyclone systems, including the re-designed Land Speed Record (LSR) steam car and the Water Speed Record (WSR) steam boat will be on display. Harry and others will discuss recent engine advances along with renewed efforts and plans to go after the LSR and WSR. Even though we are still moving in, we are anxious to welcome Cyclone’s supporters to our new home. As the company progresses, Cyclone’s intentions are to request and update filing with the SEC to recognize all of our investors and to become totally compliant and re-listed.

The Open House will begin at 4:00 PM central standard time, immediately followed by the on-line virtual tour on Cyclone’s Facebook page to be aired at 7:00 PM on October 19, 2022. We are located at 100 Tex Pack Street, Longview, TX 75604. We need to know how many will attend, so an RSVP in advance is required, either by email to Mark@cyclonepower.com or phone at 903-261-3142.

Property Deed History

Deed Date Description Grantor Grantee

8/25/2022; WARRANTY DEED VENDORS LIEN; JLF HOLDING LLC; CYCLONE PROPERTIES LLC

1/18/2022 ; WARRANTY DEED; JONES BROTHERS INVESTMENTS; JLF HOLDING LLC

CYCLONE REAL PROPERTIES LLC

Filing Information

Document Number

L22000336251

FEI/EIN Number

NONE

Date Filed

07/29/2022

Effective Date

07/24/2022

State

FL

Status

ACTIVE

Principal Address

851 COUNTRY PLACE

LONGVIEW, TX 75605

Mailing Address

851 COUNTRY PLACE

LONGVIEW, TX 75605

Registered Agent Name & Address

FRUGE, FRANKIE A

801 PINE DRIVE

#12

POMPANO BEACH, FL 33060

Authorized Person(s) Detail Name & Address

Title MGR

SCHOELL, HARRY L

851 COUNTRY PLACE

LONGVIEW, TX 33060

Title MBR

WHITE, DON

1212 S. MUSKOGEE AVE

RUSSELLVILLE, AR 72801

Title MBR

KILLORN, RAY

108 WEST PINE STREET

UNION GAP, WA 98903

Hello board. I know this is long gone, but I vaguely remember 1 of the wizbang financings to this scam by Bimini Capital Management Inc. Vero Beach fl. Can any of you smart folks verify that for me? Doin some other co. DD. TIA

Hello board. Good to see such fine minds at work. I wish the best for all here, except the cyclone crooks. So much damage done by the con that we all know and now agree upon. I won't comment on what I don't know. Stock investing.....I'm an expert.

This has been a stock selling scam from the very beginning. I know this and can prove it. So little enforcement is a sad sad state of investing. So much waste in scams. I don't bother posting here anymore obviously. But consider how many 10's of thousands of these ponzi stock selling schemes. CEO's are allowed to rob shareholders without fear. Harry Schoell is a proven LIAR AND FRAUD. as is Frankie Fruge and Chris Nelson. I know......we all know. So in closing I wish healing and better understanding of how this crime was conducted. FIRE CONGRESS.

Hi Tom,

Thanks for responding. Clearly you know a lot about steam engines. I hope you'll give me a little leeway for not describing *everything* about the engine here in a public post. The 200:1 ratio I spoke of is simply the ratio of the volumes at BDC/TDC. I'm sorry if I seemed to imply that the I'd be trying to obtain a 200:1 expansion ration of the working charge.

If we apply the combined gas laws the pressures & temperatures are so far off the chart as to be ridiculous.

Again the valve plenums are essentially sealed, and so the net forces on the valve cones should be proportional to the port areas only, with the gas-bearing area being many times the area of the ports.

The whole point of the valve plenum is to create infinitely variable valve timing of both angle & duration. Sure It's not going to be efficient at 90 degrees of admittance and 2:1 expansion, but I would expect it to make power like a hydraulic motor under those conditions. Somewhere inbetween there is an optimum. Fortunately the valve is under ECU (computer) control, so anything from full power forward to 100% reverse is simply a matter of computation. There are no mechanical considerations like conventional steam-chest a sliding valve or even the linkages of the 'Silent-Knight' rotating & nutating valve have to deal with. It's pure rotary motion.

I do get what you mean by comparing indexing to decking a bank of using gang-drills to punch 30 odd holes in one stroke. But it'll be a while before mass production bottlenecks are the long pole in the tent.

Why no master rod? Because as you were quick to recognize it a two-stroke and I'm planning on an even number of cylinders. And the master introduces variations in the piston speed depending on the cylinder number. In order to compensate for that the valves would be required to vary the phase angle of the cutoff & duration six times per revolution. That would require a colossal data table of empirical coefficients to correct. Besides the four-bar has an excellent reputation for reliability in stationary engines. The master rod's greatest advantage was in its weight savings according to P&W's testimony.

And in case I neglected to mention it, the 'block' and the cylinders are separate parts. The block is little more than a 12 sided nut with cross-drilled holes. Most of my designs start with a stubby section of DOM tubing, which gets faced off to length in a lathe. The length tolerance is the axial tolerance of the shaft in its bearings, again it can be quite loose and not cause any more trouble than requiring a washer or shim. Then that simple symmetrical nipple has the 12 flats machined onto its OD, and gets 12 kisses from the boring bar, and a chamfer. For the purposes of the prototype, a CNC machine with a rotary indexer in good working order is more than tight enough tolerance wise. The thermal expansion of the engine core will be many times the tolerance of the machining requirements.

FWIW I'd've claimed the _static_ volumetric ration was >200:1 but I left a big thick clearance between the piston & the head at TDC because I want to *measure* what the actual clearance diminishes to as the parts warm up. It all depends on how much the connecting rods stretch at high speeds. I might be able to get the squish area of the head down to 0.015" (4/0.015 = 266:1), but as I pointed out that's a heavily diminishing return.

I can understand why you would be concerned about extreme tolerances. Cyclone made a couple of fundamental choices that only make sense if one can maintain incredible precision matches. The spider & the super critical injector valves. Both of those choices required one thing to push against another thing. If only he had used 'unobtanium' it might have held together.

So just like I used to advise my junior programmers "Don't write clever code. White clear code. Someone else will be maintaining it." I took that advice to heart when I designed the engine. Yes, the 4-bar is a bit more complex than the master rod, but no one gets past "Mec.Eng.-101" without understand it. And by analogy my valve is as simple as a "4-5 siren" compared to a set of diesel injectors for Cyclone.

I had planned to build this a long time ago. I even bought a CNC machine shop to accomplish the task, but then I lost the use of my arm, then the recession hit, and after that I had to sell the shop. But I did put my kids through college, and handled the other things. Now I'm in Florida and I want to jump on (well, ease into anyway) that saddle again.

Thanks for your time. I do appreciate your comments. It's getting me to think about the multitude of details again. Helps to to limber up my muscle memory (if you will).

Best,

--Paul

Paul,

I’ve worked with gas bearings. They are excellent for applications with small radial loads and high rpm, which this valve system doesn’t appear to resemble. High pressure admission steam pressing down on your conical valve will collapse any reasonable gas film. Moreover, for operational reasons, we definitely do not want any gas film involved. High pressure steam engines suffer from severe blowby – steam leaking past the piston. You state that your expansion ratio is to be 200 to 1 (we’ll go into that later) which means your acceptable leakage is essentially zero. So, while blowby is a problem in any high pressure steam engine, it’s fatal in yours.

Lots and lots of people have tried rotary valves and, so far, none of have been commercially successful; and none of them were striking for the sort of performance that you claim. Maybe you could make it work if you aren’t running high pressures and temperatures but there’s not a lot of reason to build a commercial steam engine working at low steam conditions since internal combustion already possesses an inherent efficiency advantage over the more efficient high pressure and temperature and pressure engines. Anyhow, Dutcher industries built the most efficient piston steam engine ever encountered and they had significant blowby in the high-pressure cylinder. After doubling the piston rings, they found that they had improved things … a little bit. (And after spending a lot of money on their project, they never did match a typical gasoline engine, let alone a diesel). Their engine still had unacceptable amounts of blowby. And that’s with rings rubbing the cylinder wall, imagine how much steam will leak by if you are intentionally leaving even a small gap.

I’ll accept the 4-link motion but wonder why one wouldn’t use a typical master rod, which is much simpler and has fewer wear points, and is cheaper due to lower parts cost. All those tens of thousands of Pratt & Whitney, Wright, BMW, Nakajima, Bristol, Armstrong-Siddeley, Lycoming, Continental and other engines argue that the current method is highly effective. I’ve been involved with a number of engineering development programs over the years and have found that it pays to minimize the number of new features. That’s what killed Cyclone, they put a lot of ‘bright ideas’ into one basket and never could get the whole thing working.

I’m sorry, 12 cylinders are more costly to manufacture. With an inline engine, we can deck all the cylinders in one pass whereas you require 12 passes by indexing the part each time. The same applies for other operations which can normally be performed in gangs, such as boring, honing and drilling. As you increase the number of operations, the cycle time rises, as does the cost. Manufacturers strive to minimize these times. In any case, you need to manufacture extra pistons, linkages, bearings, screws, pins, and so on. And if you think tolerances aren’t all that important, then you haven’t seen all the CMM machines in an engine plant or its suppliers. Efficiency and durability are far more important today and you need to be holding tolerances measured in a handful of microns.

A Z06 Corvette can generate 670 horsepower on 8 cylinders, and some production 4-cylinder engines can make 300, or better. So, we can assume that 75 hp/cylinder is roughly an upper end for current engines, with roughly 35 on the lower end. These are all 4 stroke engines, whereas a single-acting steam engine is effectively a 2 stroke. Therefore, a 12-cylinder steamer should make as much power as a comparable 24-cylinder ICE having the same mean effective pressure. Twenty-four cylinders is an extremely rare configuration only used when large amounts of power are needed. I noticed that the industry trend is to reduce cylinder count for the number of horsepower, for good reasons. In any case, above about 500 HP, steam turbines become competitive with, and then surpass, piston steam engines. Everything else being even, turbines are simply a better deal for a number of reasons if you are trying to compete with engines producing the same power as a 24-cylinder motor.

If you are looking at a small engine putting out something like 100 horses, then the 12 cylinder is problematic due to the square-cube law. For a given displacement, the surface area goes up rapidly as you increase the number of cylinders and make the cylinders smaller. A 12-cylinder engine has 44 percent more cylinder wall surface than a 4-cylinder engine having the same displacement and the same ratio of bore to stroke. That 44 percent represents added friction and heat loss through the cylinder wall. Heat loss is a bad thing in a steam engine. Something similar happens to the connecting rod bearings. Oh yeah, I forgot, rotary cylinders have more external surface area than inline cylinders, which means you have more surface through which heat can leave the engine (a bad thing).

As for the 200 to 1 expansion ratio, that’s utterly impossible. You are using rotary valves having ports into the cylinder head, which is functionally similar to a slide or piston valve. These ports have height, width, and depth – especially depth; in other words, they contribute to clearance volume. Your rotary valve and cylinder head surfaces must be perfectly conical otherwise they will either leak or bind up. In order to resist bending due to the high pressure and temperature steam sitting inside the cylinder, these ports are going to be fairly deep, so that you have sufficient strength to prevent distortion. For a 200 to 1 expansion, your total volume at steam cutoff has to be ½ of 1 percent of the volume at bottom dead center. The volume in your ports will need to be larger. Just obtaining a 0.5 percent clearance is problematic enough if we ignore the ports, assuming thermal differential expansion as the engine operates and flexing in the lower end components at high output.

There’s another reason that a 200 to 1 expansion volume won’t work; you totally forgot about FMEP (Friction Mean Effective Pressure); this is the mean effective pressure in the cylinder needed to overcome all engine friction and auxiliary loads. At 200 to 1, your mean effective pressure will be much less than 1/200th of the admission pressure. This is because the steam pressure will drop by much more than a factor of 200 during expansion. The average steam pressure during the stroke won’t be enough to overcome the friction of your cylinders (half of which are pushing steam out the cylinder head, which is another force you need to overcome) not to mention the friction on all those bearings. The, of course, you need to drive the feed water pump, burner blower, condensate pump, oil pump, alternator, valve friction, and so on. You are far from the first person to realize that extreme expansion offers high efficiency – but this is theoretical efficiency and not what you will see in the real world.

Even if we ignore all the above, the 200 to 1 STILL won’t work due to ‘port blocking phenomenon’. Steam doesn’t accelerate instantly, nothing accelerates instantaneously. Since it takes a small amount of time to get up to speed, the steam experiences an extreme pressure drop. This is no big deal in an engine with longer cutoff since the following steam makes up most of the deficit. Unfortunately, you are making sure that there is no following steam. There are two consequences to this, the first being that your mean effective pressure is much lower than boiler pressure would indicate, and your power is going to drop dramatically (and you were already having problems with FMEP).

Furthermore, if we yet once again ignore all the above, there’s the matter of temperature drop during expansion. You can only expand steam just so far before it begins to condense. Such condensing is one reason the steam pressure drops in the cylinder more rapidly than the expansion ratio, water is far denser than steam and every volume of steam turning into just a drop of water produces just that much less pressure against the cylinder wall. This is the sort of thing that gets out of hand because steam is a relatively poor thermal conductor while water is pretty good; as water hits the cylinder wall it draws off heat which is then pushed out the exhaust. The incoming steam has to give up energy to reheat the cylinder, which is heat that no longer drives the engine. Turbines having very extreme expansion use reheaters between stages to prevent condensation; Abner Doble also found this necessary and his engine had nothing vaguely close to the expansion you state.

Regards,

Tom

Hi Buddy,

I remember when I first saw their demonstration on the History Channel, and I instantly knew that their 'spider' was problematic at best, and nightmarish at worst. I tried to contact them, but never got a reply.

I seem to remember the steam automobile club on Yahoo Groups (2011?), but there was too much attention being paid to the 'style' over the substance.

Anyway...

I believe the radial has many advantages over an inline design for steam. Most importantly is that my design boasts a static expansion ratio of nearly 200:1 or more conveniently a volumetric efficiency of 99.5%. What that allows me to do that no engine before has done is to control all four corners of the Rankine Cycle diagram to a greater degree than any other engine before.

It is my *expectation* that such extreme expansions will allow me to tap into some of that latent heat of vaporization that conventional steam engines can only dump into the condenser. If I'm correct, operating the stroke well into the condensing region, normally prohibited due to liquid impingement causing wear of the rotating parts, that could translate into an enormous boost in the adiabatic efficiency of the engine.

That's why I want to build two cores, one to run clean & dry, and one to run hard and ultimately to destruction. It's the only way I know for certain to show proof of concept. I certainly don't need a boat hull or any other expensive toys to accomplish my goals!

So back to the original question. Does anyone know who the original Cyclone 'customer' was? Does anyone believe that they are still interested in the 'concept' of new 'clean power' engine? Or is it more likely that the waters are still too bloody for me to even try?

Thnaks for replying, and again, sorry for the long response time.

Hi Tom,

All valid points. I'll answer them one by one, but my design is so different from Cyclone's that it's apples & oranges.

First & foremost the engine is fully encased not merely shrouded, so for all intents & purposes it looks more like the "Jupiter II" from "Lost In Space" than the beautiful machines of Pratt & Whitney featured in all those WWII aircraft.

No fragile & clunky spider bearing is used or needed, rather than have *ONE* master rod handle all of the side-to-side loads, I have utilized *two* masters & a four-bar-linkage, and/or a synchronizing gear to accomplish that requirement. All piston motions are identical, as are all piston speeds, and nothing bangs into anything else at the limit of travel. With six cylinders on power at all points in the rotation, the result is smooth torque & speed.

The block is exceedingly simple to make. The 12 sides are 30 degrees apart, and the 12 cylinders slide into the holes. They don't even have to be oriented. Plus there are no fasteners holding the cylinders in place. The shell of the engine handles that. It's like poka-yoke on steroids. Every part of the engine has rotational or reflective symmetry.

My original design was a three cylinder with variable valve rate, perfect for speed control under varying boiler outputs. Since I was trying to spin a varying load at constant speed, I reworked the design for 'programmable torque' while maintaining the ability to maintain speed with only a phase error in the shaft position.

Valve 'lubrication' is accomplished by the film of vapor suspended between the moving & stationary faces (gas bearing). And since the whole valve assembly is a plenum, it's essentially immune to binding via imbalance. While there is some force, it's comparable to poppet valve forces, but it's spread out over 100 times the area of a poppet valve seat. Did I mention that the valve speed is proportional to the number of cylinders? So for an 1800 RPM output the valve turns at a leisurely 150 RPM, and for a 1200RPM (three phase 60 HZ generator load) the valves spin at a lazy 100 RPM.

And finally, while the mass flow in the cylinder is counter-flow, the intake & exhaust are handled by separate heads with a long and narrow thermal pathway connecting them.

These are all excellent points. So let me say thank you for raising them and allowing me to address them in public. There are many more features in my engine that address a number of other challenges inherent in internal combustion engines.

My business partner had experience with motorcycle racing, and high performance automobiles. His role was to be the public face of the company, and schmooze the investors. Mine was (and is) the dark sub-basement of engineering. Since his death, I've realized that it's way past time for me to step out into the light if this thing is ever going to launch.

P.S. Sorry for the long delay, I thought the BBS would notify me upon a response to my OP.

Tom makes many good points.

Here is some empirical evidence. The Cyclone waste heat engine (WHE) went through a long development with many promised delivery dates. It was also a 6 cylinder radial with the Schoell "spider bearing". Their customer for the engine required 200 hours of continuous running under load before they would pay for the prototype.

In early 2013, Cyclone hired an engineering group at Ohio State University to fix the design and get the engine to that 200 hour threshold.

From the press release (emphasis added):

POMPANO BEACH, FL, November 5, 2013. Cyclone Power Technologies Inc. (OTCQB: CYPW), developer of the all-fuel clean-tech Cyclone Engine, announced today that it has completed the build of its next generation Waste Heat Engine, in conjunction with The Ohio State University’s prestigious Center for Automotive Research (OSU CAR). The model engine, called the WHE-DR, is currently in testing and is expected to be ready to transition into limited production by the end of this year.

The WHE-DR boasts several important advancements over the previous engine model, meant to decrease manufacturing costs and increase operational durability without loss of performance. For instance, the new engine replaces six cylinders with three slightly larger bore cylinders, and utilizes more robust and less complicated admittance and exhaust valving systems, and simplified rod bearing connections. Overall, the WHE-DR has approximately 60% fewer parts than the earlier version. Initial testing has demonstrated significantly smoother and quieter operation, which is expected to result in the successful completion of durability tests over the next two months.

Dr. James H. Durand, Director of Testing, Engineering & Software Development Services at OSU CAR, stated: “We have made great progress in a short period of time, and are very pleased with the resulting engine design of the WHE-DR. We believe this is an engine that will ultimately achieve the reliability and durability expectations of Cyclone and its customers. We feel confident that together with Cyclone’s team we will complete our project goals in the short term.”

“We are very proud of our improved engine. This is a technological and business milestone that must not be understated, as we are fast approaching our transition into phase one manufacturing with our team that we have been preparing in Ohio. For small-scale waste-to-power applications, we believe this product has enormous market potential,” stated Harry Schoell, Chairman and CTO of Cyclone.

Paul, I looked at patent 8,997,627. Some comments follow, unfortunately not as positive as I would hope.

The use of 12 cylinders seems pretty counterproductive. This makes the engine highly complicated, expensive, and difficult to build. Scaling piston bore and stroke by a factor of 1.73 would give you the same displacement using only 4 cylinders. As a benefit, the crankcase would comprise a much smaller portion of the engine's size.

The engine will not work as shown. Basically, you have copied Harry Schoell's "spider bearing" but without the bumpers. I see twelve articulating connecting rods and no master rod; this means the piston motions are all unconstrained and that the engine can thrash about violently -- and unpredictably -- rather than in a smooth motion. For an example of a correct master rod assembly you can refer to Master Rod

The next problem lies with the rotary valves, this is an old idea and well known in the art of steam engines. Rotary valves tend to suffer from a few problems. The first of these is that thermal expansion leads to temperature differentials inside an engine and this causes the various components to experience thermal expansion at different rates. Since the mating parts are expanded at different rates, they have a tendency to either bind up or become loose -- either causing the engine to stop running or leak steam.

Another problem with many rotary valves is that they are not balanced. By that, I mean that the pressure is not the same on each side and the steam either forces the valve open so that it leaks or presses it down so strongly that it rubs so hard that the parts wear down.

Related to the sentence above, rubbing parts need to be lubricated. This allows oil to flow into the cylinder and out the exhaust to the boiler. At high temperatures, the oil will decompose in the boiler and clog the tubes. Failure to lubricate will cause the valves to wear rapidly. Valve lubrication is not a good idea in highly superheated engines. Poppet valves tend to avoid these issues.

Another problem is that rubbing surfaces tend to leak unless you have a good seal at the port. I am not sure I see a provision for such.

The successful rotary valve steam engines, of which I am aware, operated at modest pressure, temperature, and rpm. This was fine back in the day when efficiency wasn't that important. As it is, I think a piston valve design would be superior to rotary valves and even these tend to leak and wear. It's hard to beat poppet valves, which is why we see them in almost all car engines.

Lubricating valves in engines having using highly superheated steam tends to cause the oil to decompose in the engine, leading to a loss of lubrication and valve failure. Heck, steam cleaners remove oil from concrete, and highly superheated steam is far more aggressive than a steam cleaner, merely keeping an oil film in place is difficult.

Your engine is also a counterflow. This tends to reduce efficiency a bit because the expanded steam (which is cooler than the admission steam) passing through the cylinder head tends to cool the head. The cooler head, in turn, cools off hot incoming steam. The cooler incoming steam produces less work in the cylinder and we experience a bit of an efficiency loss.

I'm sorry that I can't be more positive. I can provide you with references to patent literature to describe more promising designs.

Tom

Hi Paul,

Honestly, the use of a radial engine is one of the things about Cyclone that turned me off. Radial engines came to prominence with their use in aircraft. The valuable feature was that all the cylinders stuck out and could be easily air-cooled because there were no other cylinders in front of them to block the airflow. Another reason that radial engines were easily air-cooled is that all those individual cylinders caused the engine to have a very high surface-to-volume ratio.

The problem with all this is that we DO NOT want to cool off steam engine cylinders. Quite the opposite, in fact, it is preferable if they are insulated. The temperatures inside a steam engine cylinder are far lower than in an internal combustion engine, every degree of temperature lost results in lower efficiency.

Of course, Cyclone mounted their engine so that the shaft is vertical....heaven only knows why. Outside of lawn mowers and outboard motors, we hardly ever see vertically mounted engines. Mounting a radial horizontallyis problematic, however. Crankcase lubrication drops down into the lower cylinders when the engine is idle and causes a number of problems.

There's also a balance issue with radial engines. Cyclone attempted to address this with their so-called spider bearing. Of course, this resulted in making the manufacture of connecting rods more difficult. Worse yet, it involved thousands of destructive impacts per minute. Since the motion was now unconstrained, the piston movements became unpredictable. And, ironically, they interrupted the sinusoidal motion of the pistons with a sharp discontinuity that generated many times greater unbalance forces than they were trying to fix. The correct solution is that adopted by US manufacturers during WW2 -- stay with the master rod and slighly differ strokes and rod lengths to for different pistons so as to minimize unbalance. This won't cancel all the unbalance but will reduce it greatly.

Then we get to manufacturing. Radial engines are more difficult and costly to make. For instance, a 7 cylinder radial block has to be indexed every 51.429 degrees to bore the recess for the cylinder and to face off the top of the block. By contrast, an inline engine needs no indexing whatsoever for the same operation -- merely move the block linearly from cylinder bore to cylinder bore. Likewise, we are going to see additional costs manufacturing a number of bolt on cylinders versus manufacturing the whole thing en bloc. Just the extra part handling and assembly will run up the bill.

Truthfully, the only advantage that I can see in building a radial is that you can get away with a crankshaft possessing just one crankpin. This certainly reduces cost and effort in that department. However, a V-4 engine only has two pins. It will take two indexings to work on the cylinders, so that's a bit of a hassle, but still much better than a radial.

Is this the right place to inquire?

I'm assuming that anyone reading here might be interested in what Cyclone was selling, even if it was vaporware.

I've made an overture to Cyclone Power to see if they are still doing anything with their 'idea' of harnessing energy with a radial engine.

I have a better(and patented) design for a radial engine that doesn't suffer from the obvious shortcomings of the Cyclone design.

I'm looking for potential investors who are sold on the 'concept' and not completely jaded by the failure of CYPW.

I'm not looking to raise millions. I'm not going to promote a long list of 'sexy' applications that would 'require' me to have a pleasure boat.

I want to build *TWO* engines. Plus one assembly stand and one test stand. No frills, no bloat (or boat), just a pure engineering effort. Noting more, nothing less. That said, I believe the results will speak for themselves. Not dozens of hours in 15 years but 6-8 hours per day when hooked up to a solar collector, hundreds of pound-feet of torque when hooked up to a boiler, millions of revolution per day when demonstrating the capabilities of its ECU.

I cannot offer anyone who might be interested a glossy brochure, I have no slick elevator pitch. My spreadsheets for material costs are out of date since COVID. But I'm willing to talk to serious people and assuming they are technically savvy or have an trusted engineer ready to verify my claims, I am confident that I can answer any questions and assuage any doubts they might have.

FWIW: (source Wikipedia)

Oath

Before joining, members must take an oath to abide by a code of ethics called the "Obligation of an Engineer":

I am an Engineer. In my profession, I take deep pride. To it, I owe solemn obligations.

As an engineer, I pledge to practice integrity and fair dealing, tolerance and respect, and to uphold devotion to the standards and dignity of my profession. I will always be conscious that my skill carries with it the obligation to serve humanity by making the best use of the Earth's precious wealth.

As an engineer, I shall participate in none but honest enterprises. When needed, my skill and knowledge shall be given, without reservation, for the public good. In the performance of duty, and in fidelity to my profession, I shall give my utmost.

—?"Obligation of an Engineer"[1][2]

Their "Ethics" statement prohibited message board posting, as I recall. That was a non-starter from the word "go". Of course, ethics have never been a huge component of their business model given all the claimed achievements that were subsequently shown to have been false.

"I would appreciate if you would stop calling me Frankie, my name is Mike Santana.... " from this post.

Here are some accounts that posted to this board over the years. See if you can spot any similarities:

Molten Salt https://investorshub.advfn.com/boards/profile.aspx?user=587210

DinoFett https://investorshub.advfn.com/boards/profile.aspx?user=682604

msantana84 https://investorshub.advfn.com/boards/profile.aspx?user=586214

Dinblono https://investorshub.advfn.com/boards/profile.aspx?user=359345

"Molten Salt" was the most obvious. That one popped up during the final Cyclone scam, the solar electricity system. That was the one with the 1500 hp engines sold to a retirement home. Solar heat was to be stored by melting salt.

I had also found someone was deleting all the negative information in the Wikipedia article on the Cyclone Mark 5 engine in 2015, and an IP lookup showed it was done from a computer at Cyclone. Details at https://en.wikipedia.org/wiki/Talk:Cyclone_Mark_V_Engine, about half way down the page.

Quite the pattern of fraudulent misrepresentation.

Pity these two won't spend their remaining years doing hard time. On the other hand, at least that will save the taxpayers some money for their care.

When the brags themselves are pathetic, you realize just how bad the situation is.

They used to brag about having "over 1000 hours" of accumulated engine running time. Let's suppose that for once they were honest and didn't exaggerate that number. Over 15 years that's just over one hour of engine running time per week. There were approaching a dozen engine models announced, and no doubt each was rebuilt many times after it self-destructed shortly after each startup.

And then we have all the videos posted that show engines running poorly, for an average of a minute, with no load being applied.

A quick search turned up this discussion board post from "Brownie" who was something like chief "engineer" at Cyclone:

BROWNIE , 07-28-2010 03:20 PM

Registered

Harry Schoell and Brownie of Cyclone Power Technologies are building a boat and engine to set a modern day ‘World Steam Powered Water Speed Record’. The 21’ DDC hull will have one of the new 100 HP Mark Five radial Cyclone engines. The engine, termed “a heat regenerative, self contained, water lubricated, 6 cylinder, environmentally friendly, high efficiency, multi-fuel steam engine” is a modern day offshoot of the technologies of a hundred years ago.

The boat will be driven by Cyclone executive, Frankie Fruge, and named for her. The craft will be called “GG Mom”, for Great Grand Mom, and will be pit-crewed by three generations of her female offspring.

The existing record is 45 mph, set in 1903 by C.W. Flint. Frankie expects to go about 60 mph, which will break the steam boat record. It also will be the fastest boat on algae fuel, waste oil, or any one (or more) of a variety of non-imported biofuels. The date for the attempt will be announced soon, as will the date for the recovery of the Steam Land Speed Record, using the same engine type. A group of British racers recently broke the record set by a Stanley Steamer in 1906. They reached about 150 mph with a large streamliner on the salt flats. An identical Cyclone engine to GG Mom’s will power Chuk Williams streamliner.

The problem with all this talk of funding and putting engines into production is that either the Cyclone people don't understand what it takes to actually do this, or they do and are ignoring it in order to pull in bucks.

These people are talking nickels and dimes in comparison to what is needed. You don't build and test A engine. You build a whole bunch of exactly identical engines and then test them in dynamometers under all different sorts of operating conditions. One dynamometer isn't going to cut it if you want to put in the requisite number of hours in a reasonable amount of time -- it's going to take a number of machines. From what I recall, the total number of hours Cyclone has spent dyno testing all their engines isn't a lot different than what a legit manufacturer might spend testing some individual engines in their program. And this testing would occur in a period measured in weeks, not in a decade.

This outfit never had an engine designed to rational engineering principles (spider bearing, indeed!). They never had any sort of logical test program and nothing like a reasonable business model.

So, now that the company is ostensibly broke, they announce that they are going to pull a product out of their hat along with a factory to manufacture it. Funny that they can now do everything with nothing but before couldn't manage the money in a professional manner...

Grifters gonna grift.

The latest from Frankie on FB:

Uh-huh. She intentionally ignored about three years of notices from the SEC before the stock was delisted. The statements from the SEC in the delisting paperwork said there were no responses ever from Cyclone. And it wasn't a case that Cyclone couldn't afford the stamp - they could have used email.

Frankie Fruge, whose official Cyclone bio as President says she is a former auditor at Ernst & Ernst, was unable to put together a balance sheet and P/L statement each quarter for a company with no revenue? Not likely.

Fruge and Schoell were done swindling shareholders so they intentionally let the stock be delisted so their remaining thousands of victims would be completely wiped out.

They didn't need money to file those legally-required quarterly and annual reports. Those are all filed electronically. Not even postage cost was required.

"Products in production". Yeah, right. They still haven't publicly demonstrated one of their "engines" powering anything. Not Frankie's expensive custom speedboat pulling away from a dock under its own power, or even a go-kart moving one person in a parking lot. The expensive race car they had custom built that was going to break all those land speed records back in 2012 still hasn't moved one inch under the power of a Cyclone engine.

Yet the same old lie they've been telling since 2004 - products will soon be in production. Just give them some more money. Yep, remember the "family of market-ready products" they claimed to have since at least 2007, and the $25-30 million in investors' cash they've burned through (plus the $30-35 million in derivative losses also suffered by investors). 15 years later and not only no "market-ready" products any closer to being marketed, but no explanation whatsoever of why not nor of where all that cash disappeared to.

NO due to cost to bring company current. Even if they could do that 17years history proves zero to the holders of these worthless shares. sorry.

Hey thanks Chuck! I wasn't sure, I just knew the trading symbol was x'd out like cypw's....Chris Nelson...remember when he became in charge of the LSR con. ha ha ha...QSAM...well i must. ha ha GL

QPWR is still very much around.. its now QSAM because once again they changed their business model. They are now trying to get into the big pharma game.. even took like $250k in forgivable PPP loans to pay the executives.

I have been trying to educate them on the QSAM board but just as the pumpers did here, they try to silence me.

-Chuck

Is there a chance someone will buy shell and make new company?

CHRIS NELSON SCAM ATTORNEY RAN OFF WITH CYPW TECH...AND NOW QPWR IS DE-LISTED. ANOTHER SCAM BITES THE DUST.

I know for a fact we will all miss former moderator supreme friend to all BUDDY WAS HIS NAME and it was fitting.

I know my long history of posting here qualifies me.

i FEEL QUALIFIED TO BE MODERATOR as i have been here forever.

YAHOO HAS TAKEN CYPW OFF THE CHARTS. OH BOO HOO SCAM IS DEAD!

THIS SCAM BY FRANKIE AND SCHMUCK FAKE INVENTOR NOW FINALLY DEAD!

Note disappearance of Timing Pennies and buddies. Pumped and dumped this turkey!

THIS SCAM HAS HAD WORTHLESS SHARES FOR YEARS. NOW THE SEC DE-LIST!

FIRE THE SEC ! NO PROTECTION FOR INVESTORS SO WHY BOTHER PAYING THE SEC.

Awaiting announcements that this is a good thing....it wouldn't even be the most ridiculous thing posted on this site.

CYPW registration revoked:

https://www.sec.gov/litigation/opinions/2021/34-92235.pdf

Oh, there's something going on behind the scenes, alright.

Harry and Frankie are busy toasting themselves at how successfully they've cheated more than 5000 investors plus their much smaller number of customers.

Stock price has dropped back to $0.0001, so Frankie probably figured out how to print more stock again after some new bag holders bit.

They still haven't replied to any of the SEC orders: https://www.sec.gov/litigation/apdocuments/ap-3-19846.xml Any time now the SEC is going to order a permanent trading stop on CYPW.

Maybe the two old crooks will sell the shell, or maybe they figure they'll hold onto it until they can swindle a new generation of suckers.

BEHIND THE SCENES -- NOT FILING LEGALLY REQUIRED REPORTS?

|

Followers

|

234

|

Posters

|

|

|

Posts (Today)

|

0

|

Posts (Total)

|

28183

|

|

Created

|

11/29/06

|

Type

|

Free

|

| Moderators | |||

| Volume | |

| Day Range: | |

| Bid Price | |

| Ask Price | |

| Last Trade Time: |