Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.

>>> Organovo Announces Pre-Release Availability of 3D Liver Contract Services

http://finance.yahoo.com/news/organovo-announces-pre-release-availability-120500881.html

SAN DIEGO, April 28, 2014 /PRNewswire/ -- Organovo Holdings, Inc. (NYSE MKT: ONVO) ("Organovo"), a three-dimensional biology company focused on delivering breakthrough 3D bioprinting technology, today announced that it has initiated contracting for toxicity testing using its 3D Human Liver Tissue for selected clients prior to full release.

Organovo's Chairman and Chief Executive Officer, Keith Murphy, commented "Organovo has received interest in advance of our planned launch from top 15 pharma company customers, small to midsize pharma companies, biotechnology companies, and private venture capital backed pharmaceutical development firms. The compelling data already generated on the performance of the 3D Human Liver Tissue has driven this interest, we believe, and I'm pleased that our team was able in a short time to accomplish all of the hard work that allowed us to begin signing contracts. We'll be able to deliver results for proprietary compounds and other needs, while completing the work for fuller product and service launch on our original timeline."

Organovo is making 3D Human Liver Tissue technology available to clients who have specific testing needs in their preclinical drug discovery programs. The company has begun signing research service contracts and is in discussions with additional customers for near-term needs, in a limited initial release of this service. Customers with needs in a research setting that align with the preliminary offering will be able to engage in the coming months, with fuller testing services including metabolic function to be offered over time. All testing will be performed at Organovo's facility by the Company's laboratory services tissue experts.

The Company believes that its 3D Human Liver tissue model represents a new and novel approach to the drug discovery and development process, providing significant added value to preclinical assessment studies. The long lasting viability and function of the tissue allows for extended study durations in vitro, enabling the assessment of the effects of low dose or repeated dosing regimens across a spectrum of biochemical, molecular, and histologic end points.

For more information or to discuss specific study requirements, clients can contact us at sales@organovo.com.

About Organovo Holdings, Inc.

Organovo designs and creates functional, three-dimensional human tissues for medical research and therapeutic applications. The Company is collaborating with pharmaceutical and academic partners to develop human biological disease models in three dimensions. These 3D human tissues have the potential to accelerate the drug discovery process, enabling treatments to be developed faster and at lower cost. In addition to numerous scientific publications, the Company's technology has been featured in The Wall Street Journal, Time Magazine, The Economist, and numerous others. Organovo is changing the shape of medical research and practice. Learn more at www.organovo.com.

<<<

Modern Meadow -- >>> Can Artificial Meat Save The World?

Traditional chicken, beef, and pork production devours resources and creates waste. Meat-free meat might be the solution.

By Tom Foster

11.18.2013

Popular Science

http://www.popsci.com/article/science/can-artificial-meat-save-world?nopaging=1

The Meat Lab Brian Klutch

On an ordinary spring morning in Columbia, Missouri, Ethan Brown stands in the middle of an ordinary kitchen tearing apart a chicken fajita strip. “Look at this,” he says. “It’s amazing!” Around him, a handful of stout Midwestern food-factory workers lean in and nod approvingly. “I’m just so proud of it.”

The meat Brown is pulling apart looks normal enough: beige flesh that separates into long strands. It would not be out of place in a chicken salad or Caesar wrap. Bob Prusha, a colleague of Brown’s, stands over a stove sautéing a batch for us to eat. But the meat Brown is fiddling with and Prusha is frying is far from ordinary. It’s actually not meat at all.

Brown is the CEO of Beyond Meat, a four-year-old company that manufactures a meat substitute made mainly from soy and pea proteins and amaranth. Mock meat is not a new idea. Grocery stores are full of plant-based substitutes—the Boca and Gardenburgers of the world, not to mention Asian staples like tofu and seitan. What sets Beyond Meat apart is how startlingly meat-like its product is. The “chicken” strips have the distinct fibrous structure of poultry, and they deliver a similar nutritional profile. Each serving has about the same amount of protein as an equivalent portion of chicken, but with zero cholesterol or saturated and trans fats.

To Brown, there is little difference between his product and the real thing. Factory-farmed chickens aren’t really treated as animals, he says; they’re machines that transform vegetable inputs into chicken breasts. Beyond Meat simply uses a more efficient production system. Where one pound of cooked boneless chicken requires 7.5 pounds of dry feed and 30 liters of water, the same amount of Beyond Meat requires only 1.1 pound of ingredients and two liters of water.

The ability to efficiently create meat, or something sufficiently meat-like, will become progressively more important in coming years because humanity may be reaching a point when there’s not enough animal protein to go around. The United Nations expects the global population to grow from the current 7.2 billion to 9.6 billion by 2050. Also, as countries such as China and India continue to develop, their populations are adopting more Western diets. Worldwide the amount of meat eaten per person nearly doubled from 1961 to 2007, and the UN projects it will double again by 2050.

In other words, the planet needs to rethink how it gets its meat. Brown is addressing the issue by supplying a near-perfect meat analogue, but he is not alone in reinventing animal products. Just across town, Modern Meadow uses 3-D printers and tissue engineering to grow meat in a lab. The company already has a refrigerator full of lab-grown beef and pork; in fact, the company’s co-founder, Gabor Forgacs, fried and ate a piece of engineered pork onstage at a 2011 TED talk. Another scientist, Mark Post at Maastricht University in the Netherlands, is also using tissue engineering to produce meat in a lab. In August, he served an entire lab-grown burger to two diners on a London stage as a curious but skeptical crowd looked on.

Chicken-Free Strips It took more than two decades to create a vegetable-based meat analogue with a consistency and texture similar to chicken; Whole Foods began selling the packaged Beyond Meat product in spring. Courtesy Beyond Meat Revolutions tend to appear revolutionary only from a distance, and as Brown walks me to the production floor, I’m struck by how similar the Beyond Meat factory looks to any other. Nondescript metal machinery churns away. Ingredients sit in plastic bulk-foods bins. We put on hairnets and white coats and walk over to a small blue conveyor belt, where Brown’s chicken strips emerge from the machinery cooked and in oddly rectilinear form. They are not yet seasoned, he says, but they are ready to eat. At the end of the conveyor belt, the still-steaming strips fall unceremoniously into a steel bucket, where they land with a dull thud.

Staring at the bucketful of precooked strips, it’s hard to imagine a future in which meat is, by necessity, not meat. Or in which meat is grown in a manufacturing facility instead of a field or feedlot. But that future is fast approaching, and here in the heart of Big Ag country, both Beyond Meat and Modern Meadow are confronting it head on.

Each year, Americans eat more than 200 pounds of meat per person, and mid-Missouri is as good a place as any to see what it takes to satisfy that appetite. Columbia sits dead center in the state, so approaching on I-70 from either direction means driving about two hours past huge tracts of farmland—soy, corn, and wheat fields and herds of grazing cattle. Giant truck stops glow on the horizon, and mile-long trains tug boxcars loaded with grain to places as far away as Mexico and California.

Beyond Meat Factory in Columbia, Missouri, food scientists transform a mix of soy and pea proteins and amaranth into “chicken” strips. Courtesy Beyond Meat

It’s rich country that for nearly 150 years has fed the nation and the world. Yet most of the crops grown around Columbia will never land on dining-room tables but rather in giant feedlot troughs. That’s not unusual. About 80 percent of the world’s farmland is used to support the meat and poultry industries, and much of that goes to growing animal feed. An efficient use of resources this is not. For example, a single pound of cooked beef, a family meal’s worth of hamburgers, requires 298 square feet of land, 27 pounds of feed, and 211 gallons of water.

Supplying meat not only devours resources but also creates waste. That same pound of hamburger requires more than 4,000 Btus of fossil-fuel energy to get to the dinner table; something has to power the tractors, feedlots, slaughterhouses, and trucks. That process, along with the methane the cows belch throughout their lives, contributes as much as 51 percent of all greenhouse gas produced in the world.

To understand how humans developed such a reliance on meat, it’s useful to start at the beginning. Several million years ago, hominids had large guts and smaller brains. That began to reverse around two million years ago: Brains got bigger as guts got smaller. The primary reason for the change, according to a seminal 1995 study by evolutionary anthropologist Leslie Aiello, then of the University College London, is that our ancestors started eating meat, a compact, high-energy source of calories. With meat, hominids did not need to maintain a large, energy-intense digestive system. Instead, they could divert energy elsewhere, namely to power big energy-hungry brains. And with those brains, they changed the world.

As time progressed, meat became culturally important too. Hunting fostered cooperation; cooking and eating the kill brought communities together over shared rituals—as it still does in backyard barbecues. Neal Barnard, a nutrition author and physician at George Washington University, argues that today the cultural appeal of meat trumps any physiological benefits. “We have known for a long time that people who don’t eat meat are thinner and healthier and live longer than people who do,” he says. Nutritionally, meat is a good source of protein, iron, and vitamin B12, but Barnard says those nutrients are easily available from other sources that aren’t also heavy in saturated fats. “For the millennia of our sojourn on Earth, we have been getting more than enough protein from entirely plant-based sources. The cow gets its protein that way and simply rearranges it into muscle. People say, ‘Gee if I don’t eat muscle, where will I get protein?’ You get it from the same place the cow got it.”

To Barnard, the simple conclusion is that everyone should stick to eating plants—and he’s right that it would be a far more efficient use of all that cropland. And yet to most people, meat tastes good. Studies suggest that eating meat activates the brain’s pleasure center in much the same way chocolate does. Even many vegetarians say bacon smells great when it’s cooking. For whatever reason, most people simply love to eat meat—myself included. And that makes

re-creating it, whether from vegetables or cells in a lab, exceedingly difficult.

* * *

In the mid-1980s, a food scientist named Fu-hung Hsieh moved to Columbia, Missouri, to start a food-engineering program at the University of Missouri. Hsieh was coming to academia from a successful career in the processed-foods industry, at Quaker Oats, and he convinced the university to buy him a commercial-grade extrusion machine, nearly unheard of in an academic setting.

Modern Meadow Modern Meadow grows beef and pork cells in heated incubator Courtesy Modern Meadow

An extruder is one of the processed-food industry’s most important and versatile pieces of equipment, the invention responsible for Froot Loops and Cheetos and premade cookie dough. Dry and wet ingredients are poured into a hopper on one end of the machine and a rotating auger pushes them through a long barrel, where they are subjected to varying levels of heat and pressure. At the barrel’s end, the ingredients pass through a die that forms them into whatever shape and texture the machine has been programmed to produce. The mixture emerges at the far end as a continuous ribbon of food, which is sliced into the desired portions.

On one level, an extruder is a simple piece of technology—something like a giant sausage maker—but producing the desired result can be devilishly complicated. “Some people say extrusion cooking is an art form,” says Harold Huff, a meat-loving Missouri native who works with Hsieh as a senior research specialist. Around 1989, Hsieh and Huff took an interest in using the extruder to make the first realistic meat analogue. “We didn’t worry about flavor or anything else,” Hsieh tells me. “We wanted it to tear apart like chicken—it was all just about initial appearance.” They knew there wasn’t a single physical or chemical adjustment that would bring about a solution. They just had to experiment. “You have to have the right ingredients, the right temperature, the right hardware,” Huff says. “You try things, make observations, and make adjustments” for years, even decades. And so it went, until Ethan Brown came calling in 2009.

Brown, a vegan environmentalist, had been working for a fuel-cell company and had become frustrated by his colleagues’ ignorance of meat’s role in climate change. “We would go to conferences and sit there wringing our hands over all these [energy] issues, and then we’d go to dinner and people would order huge steaks,” he says. “I was like, ‘This is stupid, I want to go work on that problem.’?” To the ridicule of old friends, who joked that he was moving to the country to start a tofu factory, he started poring over journal articles and casting around for meat analogues to market—which is how he heard about Hsieh’s work.

Brown licensed the veggie chicken and began fine-tuning it with the scientists for mass consumption. “If we used too much soy, it was too firm, and if we reduced it too much, it became soft, like tofu,” Brown remembers. “It took us two years to figure that out, and it’s still not perfect.”

Lab grown meat Karoly Jakab of Modern Meadow pulls a tray of lab-grown meat from a refrigerator Courtesy Modern Meadow

As Brown and Hsieh refined the product, it began to gain notice. Bill Gates, who has adopted the meat-production crisis as one of his signature issues, published a report about the issue on his blog, The Gates Notes, in which he endorsed Beyond Meat as an important innovation. “I couldn’t tell the difference between Beyond Meat and real chicken,” he wrote. Perhaps more impressive, New York Times food correspondent and best-selling cookbook author Mark Bittman tried Beyond Meat in a blind taste test last year (at the behest of Brown, who served Bittman a burrito) and said that it “fooled me badly.” Twitter co-founder Biz Stone invested in the company last year, not long after the powerful Silicon Valley venture-capital firm Kleiner Perkins Caufield & Byers bought a stake.

“We are going to be meat. We’ll just be slaughtering plants instead of animals.”“One of the partners at Kleiner asked me to meet with Ethan and give them feedback, because they knew I was a vegan. I said yes, really as a favor,” Stone says. “I went into it thinking it’s going to be a boutiquey thing, for well-to-do vegans. Instead, I was introduced to this big-science approach. Ethan was talking about competing in the multibillion-dollar meat business. We are going to be meat, he said, we are just going to be slaughtering plants instead of animals. And here are all the ways it matters, in terms of global health, resource scarcity, number of people in the world. I was like, ‘Oh, my god. They are thinking completely differently.’”

The day I visit, the factory in Columbia is humming because the company is preparing its first shipment of packaged product to Whole Foods, which agreed to sell it nationwide after a successful trial in some California stores. On the production floor, the extruder is roaring away, pumping out strips ready for seasoning, flash-freezing, or quick grilling. A digital readout shows the configuration of the die that gives Beyond Meat its chicken-like structure. It is the company’s secret sauce, the result of all those years of research, and Brown darts over to block my view of the readout as we approach. It’s the one thing that’s not entirely transparent about the operation.

Brown has set up a taste test: three plates of Beyond Meat in three preseasoned flavors. I pop one of the Southwest-flavored strips into my mouth, and it tastes, well, a bit like soy in the form of chicken, sprinkled with chipotle dust. That’s also how it chews—very chicken-like but somehow just shy of chicken. After all the buildup, I’m a little disappointed. But I also have the distinct impression that I’m eating something more like meat than veggies. And I’m eating it unadorned, as opposed to in Bittman’s burrito.

Over the course of the next month, I replace boneless chicken breasts with the lightly seasoned strips in various meals: an omelet with spinach and feta, a plate of fajitas, a wok-ful of fried rice. I’m never once fooled that it’s chicken. For me, chicken is the whole sensory package—crisp skin, the roasting pan, the juices—and when I want one, I make one. But when I want lean, chewy protein as a flavor medium in some other dish, I find I don’t care whether it comes from an animal or vegetable. But what if it comes from neither?

* * *

On the other side of Columbia, at a biotech start-up incubator on the edge of the University of Missouri campus, the scientists at Modern Meadow are working on a very different solution to the meat-production crisis. When I visit, a 3-D printer about the size of an HP desktop unit streams a line of yellowish goo onto a petri dish. Back and forth, the machine creates a series of narrow rows a hair’s breadth apart. After covering a few inches of the dish, the printer switches direction and lays new rows atop the first ones in a crosshatch pattern. There’s no noise but an electric whir, no smell, nothing to suggest that the goo is an embryonic form of meat that will turn into a little sausage. Once the printer finishes its run, the result looks something like a large Band-Aid.

To reach this stage, about 700 million beef cells spent two weeks growing in a cell-growth medium in a wardrobe-size incubator. The cells were then spun free in a centrifuge, and the resulting slurry, which is the consistency of honey, was transferred to a large syringe that acts as the business end of the printer.

The printed cells will now go back into an incubator for a few more days, during which time they will start to develop an extracellular matrix, a naturally occurring scaffold of collagens that gives cells structural support. The result is actual muscle tissue.

The technology in front of me is the work of Gabor Forgacs, a Hungarian-born theoretical physicist who turned to developmental biology mid-career. In 2005, he led a team that developed a process to print multicellular aggregates rather than individual cells. His printer produces physiologically viable tubes of cells that can adhere to create large complex structures.

Modern Meadows Co-Founders Gabor and Andras Forgacs, the father and son co-founders of Modern Meadow Courtesy Modern Meadows

In 2007, Gabor and his son, Andras, helped found a company called Organovo that uses Gabor’s technology to print human tissue for medical applications (pharmaceutical testing, for instance) and aims one day to print functioning human organs for transplants. Gabor was the science mind behind the company, and Andras worked in various roles on the business side.

“Fairly early on, people asked us, ‘Hey, could you make meat?’?” Andras remembers. “And we were pretty dismissive of the idea”—it was simply too far from Organovo’s mission. But by 2011, Organovo had brought on a new management team and laid plans to go public (which it did in early 2012). Gabor began brainstorming new projects with his two closest scientific collaborators—Françoise Marga and Karoly Jakab. Andras, meanwhile, had moved to Shanghai to work in venture capital. He saw how diets in China were changing and how much of the meat came from places as far away as Latin America and Australia.

“If we can make living tissues, then we can certainly make food-grade ones.”That confluence of factors made bio-fabricated meat appear more attractive. Even better, Gabor suspected meat would be simpler to produce than functioning human parts. “If we can make living tissues, then certainly we can make food-grade tissues, which don’t have to be as exacting,” he says. “We do not have to worry about immune compatibility, for instance.”

In late 2011, Andras returned to the U.S., and the team landed a USDA Small Business Innovation Research grant shortly thereafter. It then received a grant from Breakout Labs, an arm of Peter Thiel’s foundation. (Thiel is a co-founder of PayPal and a tech investor and futurist.) With help from the grant, Andras set up a business office at Singularity University on the campus of NASA’s Silicon Valley research park, and Gabor set up his scientific headquarters in Columbia. Modern Meadow was born.

As ghoulish as growing lab meat sounds, the concept has a long history, and not just in science fiction. In 1931, Winston Churchill wrote, “Fifty years hence, we shall escape the absurdity of growing a whole chicken in order to eat the breast or wing, by growing these parts separately under a suitable medium.” He was wrong about the date, but the same sentiment drives the meat-alternatives community today. If you consider the conditions under which meat is produced—how the animals are treated and how much waste is involved—factory farming, not tissue culture, seems the ghoulish option. By comparison, lab meat looks both humane and sensible; a study for the EU predicted that, if produced on a large scale, lab-grown meat would use 99.7 percent less land and 94 percent less water than factory farming, and it would contribute 98.8 percent fewer greenhouse gases.

Over the past few decades, a handful of scientists have pursued lab-grown meat, most notably Mark Post in the Netherlands. Post created the burger for his London taste test using a different tissue-engineering process that involves growing cells around a cylindrical scaffold. According to Isha Datar, the director of New Harvest, a nonprofit research and advocacy group that focuses on meat alternatives, Post’s process may actually be “more amenable to mass production, theoretically” than Modern Meadow’s 3-D printing. On the other hand, Datar points to the head start Modern Meadow has: “It’s an actual business. The other groups are all academic, and you never know if they have the power to get out of the lab.”

By August, Modern Meadow was experimenting with other bio-assembly techniques that could quickly lay down large cell arrays. And Mark Post revealed his own high-profile Silicon Valley backer: Google co-founder Sergey Brin, whose track record bringing improbable products to market isn’t bad.

But being first to market doesn’t matter if the meat coming out of the labs isn’t appetizing. Post’s burger got tepid reviews from his two tasters. And Modern Meadow’s current product is hardly even recognizable as meat; it lacks blood and fat, which are responsible for most of actual meat’s color, flavor, and juicy texture. Karoly Jakab shows me a couple of the samples he’s storing in the lab refrigerator: They look like tiny beige-gray sausages—fully grown, rolled-up versions of the Band-Aid I saw coming out the printer—about the size of an infant’s pinkie finger.

Lab-Grown Burger In August, Mark Post of Maastricht University in the Netherlands served a lab-grown hamburger to two diners. One said it “wasn’t unpleasant.” REUTERS/David Parry/poo

To make the meat more appealing, Modern Meadow has enlisted the Chicago chef Homaro Cantu, whose restaurant, Moto, has become an icon of molecular gastronomy. For Modern Meadow, he’ll be working on what Andras calls “last-mile issues” like texture, flavor, appearance, and mouthfeel by, for instance, suggesting how much fat to add and what kind. And sometime in the next couple of years, Andras says, with Cantu’s help, Modern Meadow plans to start conducting invitation-only tasting sessions, where friends of the company will sign waivers and sample dishes.

There will be plenty of technical hurdles just to get to that point, but putting lab-grown meat in the hands of the masses could be even trickier because there is no regulatory precedent. Meat falls under the USDA’s jurisdiction, but Andras expects the FDA to be involved too. “They have the sophistication and understanding of how tissue engineering works in medicine,” he says. Approval could take at least 10 years.

In the meantime, Modern Meadow needs to make money, so the team is focusing heavily on growing leather, which turns out to be easier than meat and won’t face as many regulatory hurdles. Gabor hands me a pepperoni-size disc of dark-brown leather, indistinguishable from the stuff used in one of my favorite pairs of shoes. It even smells like leather. It is leather. Much as the company is partnering with chef Cantu on perfecting the meat, it’s in talks with fashion brands and automakers to create products with the lab-grown leather.

* * *

Ethan Brown folds his lanky frame into one of the metal chairs at the Main Squeeze, an organic juice café in downtown Columbia, and begins talking about how he’ll define success for Beyond Meat in the near term. “I want to be in the meat aisle,” he says. “You go to the grocery store, and they sell meat in one section and vegetable-based proteins in another section. Why are they penalizing the non-meat?” He points to the rise of soy milk and its eventual inclusion in the dairy aisle—which helped to drive a 500 percent increase in sales since 1997—as his model.

Ethan Brown Ethan Brown of Beyond Meat Jennifer Smith/Beyond Meat

“Our earliest adopters are the vegans and locavore types who prefer tofu and beans and quinoa,” he says. “But the sweet spot for us is folks who are simply cutting down on their meat consumption. They still eat at Taco Bell, but they know they shouldn’t do it that much.”

There’s an uncanny valley of food. Until engineered meat is perfect, it will be creepy.

Appealing to those people with a near-perfect imitation of meat makes sense on one level. But there’s also a risk, Andras Forgacs says. In the world of animation and robotics, there’s a concept called the “uncanny valley,” which states that if a simulated human too closely resembles the real thing, it will repel people. “There’s also an uncanny valley of food,” Andras says. “Until it becomes perfect, it’s going to be creepy.”

I’ve seen the uncanny valley response up close, when I’ve tried to serve my wife Beyond Meat. She has no problem eating processed meats that bear no resemblance to the animal they come from: hot dogs, say, or on the high end, goose liver pâté. And she’ll eat other soy proteins, such as tofu, that don’t pretend to be meat. But she won’t touch Beyond Meat. To her, it imitates the real thing just a little too closely.

Modern Meadow may simply back away from the uncanny valley, rather than try to cross it. “I have an analogy that goes back to Organovo,” Gabor says. “We will never be able to print a heart exactly as it appears in nature—but we don’t have to. What we need is to create an organ that functions as well as your heart, or better, from your own cells so that it works in your body. That we can do. And the same goes for meat. What we are going to put into your mouth is not what you’d get when you slaughter a cow. But from all other points of view—nutritional value, taste—it will be just like the real thing. You recognize it as meat, but it’s a different kind of meat.” Like a hot dog or goose liver pâté.

And if fake meat doesn’t have to perfectly mimic real meat, it can be made even better than the real thing. The teams at Beyond Meat and Modern Meadow envision super meats enhanced with things like omega-3 fatty acids and extra vitamins. “You could eat a Beyond Meat Philly cheesesteak that lowers your cholesterol and gives you sexual prowess,” Brown says. He is only half joking.

However they move forward, neither company envisions its product entirely replacing meat, nor do they see themselves as being in competition with each other. Isha Datar of New Harvest predicts a portfolio of approaches that would address the meat-production crisis: lab-grown meat and plant-based meats, yes, but also sustainably raised livestock and less meat-intensive diets. A 2012 study at the University of Exeter in the U.K. calculated the degree to which diets must change in order to feed the world in 2050 and stave off catastrophic climate change. The researchers found that average global meat consumption would have to decrease from 16.6 percent of average daily calorie intake to 15 percent. That may not sound like much, but it translates to roughly halving the amount of meat in Western diets—a major change, but conceivable with high-quality meat alternatives.

One theme cuts through all those visions of the future: Educated consumers who have the benefit of total transparency into the meat-production process. Brown has considered installing cameras on the Beyond Meat production floor and streaming the video online so people can see for themselves how harmless the process is. The contrast to the secretive policies of industrial slaughterhouses would be stark.

Andras Forgacs Courtesy Modern Meadow

Andras Forgacs imagines something even more dramatic. He pictures Modern Meadow’s production facilities as regional petting zoos. “You’d need to replenish the cell source periodically so all we’d really need is a few animals from which we could take occasional biopsies. They’d be like mascots. Other than getting poked every month or so, they would lead these perfectly charmed lives.” People could come meet the animals as they grazed and then make their way into a facility to watch a giant 3-D printer stream the cells onto trays, where they would grow into pork chops and steaks.

“Would you rather visit a slaughterhouse and see a cow get killed, skinned, and disemboweled right before you go eat a steak dinner, or would you rather visit a petting zoo and a facility that looks a little Willy Wonka–ish and then go eat the meat right afterward?”

It’s a dream, but Andras insists it’s not outlandish. “Bio-fabrication already exists, and it’s inevitable that in the coming decades there will be applications beyond medicine—consumer applications, like food.” The question is whether the world will be ready for them.

Tom Foster’s last piece for Popular Science, about the Leap Motion interface, appeared in the August issue. This article originally appeared in the November 2013 issue of Popular Science.

<<<

Modern Meadow - Making Leather and Meat Better

Modern Meadow applies the latest advances in tissue engineering to develop novel biomaterials to address some of our most pressing global challenges. We develop cultured leather and meat products which require no animal slaughter and much lower inputs of land, water, energy and chemicals.

Website -

http://modernmeadow.com/

Organovo -- >>> Backround info on Organovo founders Andras Forgacs and Gabor Forgacs, from the Modern Meadow website -

>>> Modern Meadow was founded in 2011 by some of the leading tissue engineers and co-inventors of bioprinting. Since its inception, the company has attracted a world class team, advisors and investors who share the aim of leveraging advances in tissue engineering to solve global resource challenges.

http://modernmeadow.com/team/management/

Andras Forgacs, Co-founder and Chief Executive

Andras is an entrepreneur and venture investor in technology and life science. He co-founded Modern Meadow in 2011. Previously, he had also co-founded Organovo, a leader in tissue engineering which pioneered the use of 3D bio-printing to create human tissue for a range of medical applications. Organovo’s bio-printer was named one of the top inventions of 2010 by Time Magazine and the company was recognized by MIT Technology Review on its TR50 list of most innovative companies for 2012.

Andras also served as Managing Director with Richmond Global, an international technology-focused venture fund. Previously, Andras was a consultant in the New York office of McKinsey & Company focused on biopharma and private equity. Earlier, he was a founding member of Citigroup’s corporate and investment banking e-commerce group where he led a team that developed award winning financial technology products and advised large cap corporate clients on a range of corporate finance challenges.

He is also co-founder and Chairman Emeritus of the international non-profit Resolution Project. Andras is a Kauffman Fellow with the Center for Venture Education and a Term Member with the Council on Foreign Relations. Andras holds an MBA from the Wharton School of Business and a Bachelor of Arts with honors from Harvard University.

Gabor Forgacs, Co-founder and Chief Scientific Officer

Dr. Gabor Forgacs is a theoretical physicist turned bioengineer turned innovator and entrepreneur. He is the George H. Vineyard Professor of Biological Physics at the University of Missouri-Columbia, the Executive and Scientific Director of the Shipley Center for Innovation at Clarkson University and scientific founder of Organovo, Inc. and Modern Meadow, Inc.

He was trained as a theoretical physicist at the Roland Eotvos University, Budapest, Hungary and the Landau Institute of Theoretical Physics, Moscow, USSR. He also has a degree in biology. His research interests span from topics in theoretical physics to physical mechanisms in early embryonic development.

He is the co-author of the celebrated text in the field, “Biological Physics of the Developing Embryo” (Cambridge University Press, 2005) that discusses the fundamental morphogenetic mechanisms evident in early development. These mechanisms are being applied to building living structures of prescribed shape and functionality using bioprinting, a novel tissue engineering technology he pioneered. He is the author of over 160 peer-reviewed scientific articles and 5 books.

He has been recognized by numerous awards and citations. In particular, he was named as one of the “100 most innovative people in business in 2010” by FastCompany.

Francoise Marga, Co-founder and Senior Scientist

Dr. Francoise Marga is a co-founder and a Senior Scientist at Modern Meadow. She joined Dr. Forgacs’ laboratory in 2003 and played a crucial role in the development of the bioprinting technology and its two medical applications: the vascular graft and the nerve graft.

She is co-inventor on several related patents, either licensed to Organovo or key to the foundation of Modern Meadow. She was the lead investigator for both companies in their first awarded SBIR grants.

Francoise is a food biochemist by training. Before joining Dr. Forgacs’s laboratory, she worked on the biochemical and biophysical characterization of biopolymers. She holds a PhD from the University of Technology Compiegne (UTC) in France. She came to Canada as postdoctoral fellow and worked at Armand-Frappier Institute in Laval, Quebec on polysaccharide-degrading enzymes. She then moved to Lafayette, LA and worked on cuticle composition in relation with its elastic properties. She came to Columbia as a research associate in the Department of Biological Sciences prior to joining the Forgacs Lab. She is the co-author on several seminal publications on the bioprinting technology.

Karoly Jakab, Co-founder and Senior Scientist

Dr. Karoly Jakab is a co-founder of Modern Meadow. He worked with Dr. Forgacs for over a decade on several biophysics research projects and developed extensive expertise in the biomechanics of cells and tissues.

Karoly’s contribution was instrumental in developing the first generation bioprinters used to create living 3D tissues for regenerative medicine. He co-authored key publications related to bioprinting in the field of biological physics, tissue engineering and biotechnology. Beside his contribution to the basic science in tissue and cell biomechanics, he is also co-inventor on core bioprinting patents currently licensed in the industry of bioprinting.

A physicist by training with strong engineering skills, he designed and built several prototype research instruments and devices, many of them crucial elements in the company’s current manufacturing process.

Karoly holds a Ph.D. in biological physics, his training includes two postdoctoral fellowships in developmental biology (University of Virginia) and vascular tissue engineering (University of Missouri), respectively.

Sarah Sclarsic, Director of Business

Sarah Sclarsic is an entrepreneur with a background in biotechnology. She co-founded Getaround, an innovative peer-to-peer carsharing company. At Getaround Sarah guided operations and business development, crafting novel business relationships within the transportation and insurance industries. She previously worked in venture capital as an investment analyst with Canaan Partners, focusing on early-stage technology companies.

Sarah holds a BA in Bioethics and Public Policy from Harvard University, where she also performed research in a molecular and cellular biology lab. After college she worked in sub-Saharan Africa helping the Clinton Foundation scale up treatment of HIV/AIDS. Sarah is a graduate of Singularity University, a technology studies program based at NASA Ames, and has advised early-stage startups on business strategy, product, and business development.

Hemanth Varadaraju, Process Engineering

Hemanthram Varadaraju manages process engineering for Modern Meadow. Prior to Modern Meadow, he worked for Lonza (Walkersville, MD) as a process engineer to scale-up cell therapy manufacturing processes. He has a broad experience in de-risking operations involved in stem cell manufacturing processes from upstream to downstream. Apart from process development, he has expertise in process modeling to evaluate cost of goods, debottlenecking and optimizing workflow. Earlier, Hemanth was an intern at Monsanto and contributed for process development engineering.

Hemanth holds a Masters in chemical engineering from South Dakota School of Mines and Technology and his graduate research includes applications of nanofiber membranes as an adsorptive medium for bioseparations.

Ryan Kaesser, Research Associate

Ryan Kaesser is a graduate from the University of Missouri – Columbia with a Bachelor of Science in Biological Sciences. During his studies he interned and performed laboratory research on autoimmune disorders. In 2009, he joined the Forgacs Lab. While there he worked with the current Modern Meadow team helping to develop the technology that would lead to the launching of the company. Ryan joined Modern Meadow in June 2012.

<<<

Organovo related videos -

Sharon Presnell, Ph.D., Chief Technology Officer & EVP of Research & Development

Organovo -- >>> Can Autodesk and Organovo Bring Tissue Engineering to a Hospital Near You?

By Maxx Chatsko

April 22, 2014

http://www.fool.com/investing/general/2014/04/22/can-autodesk-and-organovo-bring-tissue-engineering.aspx

Tissue engineering has captured the imagination of mainstream media and investors alike. In the future, will humans be able to bioprint living tissue to repair and replace ailing or diseased tissue? Could companies eventually print functional cancerous tissue in the lab to hasten the development of oncology drugs? Tissue engineering may be in its infancy today, but it could be getting closer to reality with companies such as Organovo Holdings (NYSEMKT: ONVO ) developing futuristic technology platforms.

While I think investors got a little ahead of themselves with Organovo in 2013, especially considering its lengthy timeline for product revenue, I was surprised to learn the company was a leading partner with Autodesk (NASDAQ: ADSK ) for a next-generation meta platform using computer-aided design for characterizing biology, or bioCAD. The collaboration was announced in January 2013, but I did not think much about it at the time. However, my recent work in the synthetic biology industry, one of the four fields targeted by the same bioCAD platform, has led me back to Organovo.

Should the collaboration change how investors think of Organovo? Heck, should investors think differently about Autodesk, which isn't traditionally associated with life sciences? I recently spoke to Carlos Olguin, head of the Bio/Nano/Programmable Matter Group at Autodesk Research, to find out more about a project - Project Cyborg - that could impact both Autodesk and Organovo.

What is Project Cyborg?

Project Cyborg is a Web-based software meta platform, or a platform that will serve as a foundation for more specialized platforms, that aims to more effectively characterize biology and nano-matter. If successful, engineers will be capable of accurately designing virtual living systems -- and finding fatal flaws in their designs -- before creating a physical real-world prototype. That would drastically reduce the time and money spent on an inefficient design cycle for producing organisms and biological systems.

Think about it: Today, designers and engineers can use Autodesk software to create, manipulate, simulate, model, and optimize virtual macro objects ranging from bicycles, to skyscrapers, to entire cities in amazing detail before a single aluminum frame is built or slab of concrete is poured. Engineers can test how a new airplane design will react to real-life conditions at an altitude of 36,000 feet before shoving a pilot in the cockpit and slamming the door. Can you imagine creating thousands of airplane prototypes, performing tests to collect data, and then calibrating the final results for each plane before having a marketable product? Maybe not, but that's exactly how we design biology today.

What makes that level of efficiency possible for macro objects? We understand macro systems and how changing variables will affect how physical objects interact with their environment. We have equations that can accurately model these interactions as each variable is altered. Unfortunately, the same is not true for smaller, more complex systems, such as a living cell. There are many interdependent variables that affect living systems, which makes it nearly impossible to get enough predictability with biology (given our current understanding). For instance, changing the temperature in a bioreactor or bioprinter by several degrees can affect cell division (affecting contamination probability), protein folding (affecting enzyme functionality), feedstock uptake (affecting time to product), dissolved oxygen content (affecting cell growth), and, ultimately, the products created by cells (affecting margins), among other variables.

Suddenly, accurately studying how temperature affects your system doesn't seem so easy, especially if you have to conduct each run in the real world in real time. The goal of Project Cyborg is to create a software tool for researchers and engineers to design biology virtually in much the same way an architect can build a house or an engineer a plane. By creating more accurate models, Autodesk and Organovo will increase the predictability of their systems and reduce the number of prototypes needed to achieve a final design.

What can Project Cyborg do for Organovo?

Well, almost exactly what is described above. Autodesk and Organovo are working together to make tissue engineering, or 3-D bioprinting, more accurate and predictable. Despite the hype surrounding Organovo's capabilities, it is important to understand that the tissues currently created by the NovoGen bioprinter are only several cell layers thick. Building larger models for toxicology testing would, presumably, lead to more accurate results and allow tissues to survive even longer than 40 days -- increasing the value to the pharmaceutical industry and selling price of each. But the number of iterations needed to go from a tissue several cell layers thick to one many times larger (that retains functionality) would require a terrifying lengthy process if conducted solely with real-world prototypes. Forget having a complete organ ready for transplantation with that design cycle.

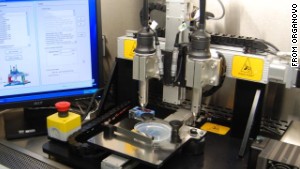

The NovoGen bioprinter, and future iterations of the hardware, could disrupt the health care industry in profound ways. Source: Organovo.

Autodesk and Organovo are tackling the problem from several unique angles. First, the pair is integrating hardware (3-D bioprinters) into Project Cyborg to enable an end-to-end platform. That will smooth out any errors from the current fragmented approach that takes data from software and hardware that do not communicate with each other. Second, the collaborators are removing the labor-intensive laboratory steps with automated solutions. It is still a distant reality, but it is not impossible to think that a future fabrication facility for human tissues would operate almost entirely autonomously. A server could receive a request from a hospital or clinic for a tissue type, a liquid-handling robot could fetch reagents to feed to the 3-D bioprinters, and a functional made-to-order tissue could come out on the other end -- reducing overhead and in-house requirements for human scientists. Finally, what better way to learn what you don't know than attempt to model it with software? Researchers will discover which relationships they don't understand, attempt to understand them, and then integrate the interaction into the software platform.

Foolish takeaway

I believe the collaboration between Autodesk and Organovo will be necessary to create larger fully functional tissues on a timeline that satisfies investors and with accuracy that satisfies regulatory guidelines. It does not justify a lofty valuation for Organovo just yet, nor does it guarantee success. But the way I look at it, someone is going to figure out how to predictably characterize biology for tissue engineering applications eventually. Organovo seems to have the head start necessary to allow for successful platform development, and investors should not take for granted a future-focused collaboration with an industry leader such as Autodesk. Nonetheless, I'll stick to my previous opinion and remain on the sidelines until more meaningful product development and revenue becomes apparent.

<<<

>>> Organovo comments on misleading and inaccurate reports (ONVO) : Co commented on recent reports published by two unaffiliated firms:

"Over the past two months, new and unknown firms have issued articles and reports on Organovo, without speaking to Organovo management for information or perspective on Organovo's business or opportunities. One firm appears to have been formed in Feb 2014 and has not issued any other reports other than on Organovo; the other firm has a mailing address at a virtual, rent-an-office."

"We have had the opportunity to review these reports in detail and can confirm that they contain inaccurate information and that they are exceptionally -- and likely intentionally -- misleading. Based on the source of the reports and the blatantly negative tone, we believe they were issued by or at the request of a short seller or short-sellers, who may profit from a decrease in Organovo's stock price following the issuance of these kinds of reports."

"Organovo remains focused on the development of 3D human tissues, including remaining on track for launch of its 3D Liver product in 2014. The Co believes, based on the feedback from its collaborators and scientific advisors, that the demonstrated performance of the 3D Liver to date provides it with the opportunity to redefine the category of in vitro assays. The Co's opportunities in in vitro assays include liver, cancer, skin, and kidney tissue markets and in 2013 it signed research collaborations with top corporate and academic partners in three of those areas. In 2014, Organovo has signed collaboration with the US National Institutes of Health to develop eye tissues and to integrate 3D bioprinting with traditional drug screening technologies."

<<<

http://finance.yahoo.com/news/inplay-briefing-com-055139997.html#onvo

>>> Printing a bit of me

Bioprinting: Building living tissue with a 3D printer is becoming a new business, but making whole organs for transplant remains elusive

The Economist

Mar 8th 2014

http://www.economist.com/news/technology-quarterly/21598322-bioprinting-building-living-tissue-3d-printer-becoming-new-business

IN A state-of-the-art clean room, a scientist clad in a full-body containment suit, a hair net and blue gloves is preparing some printing cartridges—filled not with ink but a viscous milky liquid. Next to her sits a computer connected to a machine that resembles a large ice-cream dispenser, except that each of its two nozzles is made of a syringe with a long needle. Once the scientist clicks on the “run program” button, the needles extrude not a vanilla or chocolate-flavoured treat, but a paste of living cells. These bioinks are deposited in precise layers on top of each other and interspersed with a gel that forms a temporary mould around the cells.

Forty minutes later, the task is finished. Depending on the choice of bioink and printing pattern, the result could have been any number of three-dimensional biological structures. In this case, it is a strand of living lung tissue about 4cm in length and containing about 50m cells.

Since its inception in 2007, researchers at San Diego-based Organovo have experimented with printing a wide variety of tissues, including bits of lung, kidney and heart muscle. Now the world’s first publicly traded 3D bioprinting company is gearing up for production. In January samples of its first product—slivers of human liver tissue—were delivered to an outside laboratory for testing. These are printed in sets of 24 and take about 30 minutes to produce, says Keith Murphy, the firm’s chief executive. Later this year Organovo aims to begin commercial sales.

Each set consists of a plate with 24 wells containing a piece of liver tissue 3mm square and 0.5mm deep. Although prices have not been fixed, a set of tissues like this can sell for $2,000 or more for laboratory use. It might seem expensive, but it could save pharmaceutical companies a lot of money. This is because Organovo’s research indicates that the slivers of liver respond to drugs in many ways like a fully grown human liver would. If this is confirmed by outside testing, researchers could use the printed tissues to test the toxicity of new drugs before deciding whether to embark on expensive clinical trials with patients.

The invention of 3D printing in the 1980s provided a technology now used to manufacture everything from aircraft parts to prosthetic limbs. But the promise of 3D bioprinting is even larger: to create human tissues—layer by layer—for research, drug development and testing, and ultimately as replacement organs, such as a kidney or pancreas, for patients desperately in need of a transplant. Bioprinted organs could be made from patients’ own cells and thus would not be rejected by their immune systems. They could also be manufactured on demand.

At present only a handful of companies are trying to commercialise the production of bioprinted tissues. But Thomas Boland, an early pioneer in the field, says that plenty of others are interested and estimates that about 80 teams at research institutions around the world are now trying to print small pieces of tissues as varied as skin, cartilage, blood vessels, liver, lung and heart. “It’s a wonderful technology to build three-dimensional biological structures,” says Gabor Forgacs, who co-founded Organovo in 2007 and was the company’s scientific mastermind.

Don’t hold your breath

Organ and tissue structures vary in complexity, and some are much harder to make than others

Despite all this interest, the age of organ printing is not just around the corner. Not surprisingly, printing with living cells to create tissues is much more complex than printing objects in plastic or metal. Printing whole organs made from human cells was Dr Forgacs’s original idea when he started Organovo, but it has proved elusive. Yet he and other tissue engineers are hopeful that it will, one day, be possible.

Dr Boland started experimenting in the summer of 2000 using an old Lexmark inkjet printer that was sitting in his former lab at Clemson University in South Carolina. (He is now director of biomedical engineering at the University of Texas at El Paso.) At the time he wasn’t looking to print 3D biological structures, just proteins or cells in two-dimensional patterns. As it turned out, typical inkjet nozzles then were just large enough to accommodate most human cells, which tend to be around 25 microns in diameter (a micron is a millionth of a metre). “The printers at the time were really fulfilling all of the requirements that we would use for cell printing,” says Dr Boland.

Building additively

The potential of the technology quickly became apparent to other scientists. By the early 2000s, several research teams from different laboratories had begun to develop or modify printers to print cells in three dimensions. In Dr Boland’s case, he simply added to an HP printer a platform that could move up and down. In 2003 he filed for his first cell-printing patent and collaborated with Dr Forgacs and three other colleagues on a paper for Trends in Biotechnology in which they predicted that in this century “cell and organ printers will be as broadly used as biomedical research tools as was the electron microscope in the 20th century.” And in September 2004 the University of Manchester in Britain hosted the First International Workshop on Bioprinting and Biopatterning, with 22 speakers from ten countries.

Around the same time, Dr Forgacs began developing the technology that became the basis for Organovo. He devised a technique that could print a large number of cells at one time. Instead of an inkjet’s tiny nozzle that allows only droplets with individual cells to squeeze through, Dr Forgacs invented an extrusion-based printing process that uses a syringe with a needle or micropipette with an orifice that may be as large as several hundred microns. That made it possible to deposit large cell aggregates, in spheroid or cylindrical form. Pressure was applied to push them out, typically using an automated plunger.

Bioprinting is very different to standard tissue-engineering, in which cells are cultured and then seeded onto individual biodegradable moulds or scaffolds whose shapes resemble that of the organ or tissue they are replacing. Depending on the architectural needs of the organ and its function, a scaffold’s properties and structure need to vary as well, says Anthony Atala, a leader in this field and director of the Wake Forest Institute for Regenerative Medicine in North Carolina.

In the case of a blood vessel, the scaffold would have to be thin and elastic. “The scaffold really is acting like a prosthesis, like a device, until the cells are able to take over and lay down their own matrix,” Dr Atala explains. The timing of the scaffold’s demise is critical, he adds. If it degrades too quickly, the transplant is going to fail. But if it degrades too late, after the cells have made their own structure, the patient may end up with scarring.

Dr Atala and his team used to create scaffolds by hand and seeded the cells with a hand-held pipette. 3D printing helped to scale up the process, automate it and make it more precise because the printers run under computer control. His institute now has half-a-dozen 3D printers at its disposal, and in most cases researchers print the scaffold and the cells together. That way, says Dr Atala, “we could not just create one organ at a time, but create many organs at the same time.”

Organ and tissue structures vary in complexity, and some are much harder to make than others. From an architectural standpoint, flat structures, like skin or cartilage, are less complex than tubular ones, such as blood vessels or windpipes, says Dr Atala. Hollow, non-tubular organs, like the bladder, stomach or uterus, are trickier. But the most complex are relatively solid organs, such as the heart, liver or kidneys, which consist of many more cells and an extensive vascular structure.

Transplanted parts

So far, surgeons have been able to implant a variety of engineered flat, tubular and hollow tissues into patients, including skin, cartilage and muscle. Dr Atala has also successfully implanted lab-grown bladders and urethras into young patients. But solid organs are another matter. “That”, he says, “is really the next frontier.”

All tissue engineers have the same goal—to create human organs for transplant—but their approaches differ. In particular, they are divided on how much of a support structure or scaffold they need to provide for the cells, and what building materials are the most suitable.

Dr Forgacs believes that any type of scaffold interferes with a cell’s natural biology. His approach relies on the cells’ intrinsic ability to develop an innate shape and structure, which is akin to the differentiation and developmental processes that occur inside an embryo. Instead of a scaffold he uses what he calls “biopaper”, a water-based gel that is printed along with the bioink and surrounds the cell aggregates. Dr Forgacs calls this process “scaffold-free” bioprinting. The gel is not going to be part of the biological tissue, but a structure that holds the printed material together until the cell clusters themselves begin to fuse.

Because gels could interact with the cells, it is best to remove them quickly, usually in less than 24 hours, concurs Mr Murphy. “Our goal is to make something that’s 100% tissue as quickly as possible,” he says. In the case of Organovo, scientists do it by formulating the gel so they can dissolve it chemically or physically peel it off.

Brian Derby of the University of Manchester and author of a review in Science on printing tissues and scaffolds, emphasises that in some cases it is beneficial to use a scaffold. “People use scaffolds for a reason,” he says, “and that’s because gels have little or no structural integrity.” Rigid tissues, such as bone, require a structure that provides mechanical strength while the cells lay down their own matrix.

One of the biggest challenges facing tissue engineers is creating the necessary blood flow and vascular structure to supply organs with nutrients and oxygen, so they can thrive and survive in the long term. The heart and other solid organs in particular require an entire vascular tree, which is comprised of large blood vessels that branch into smaller and smaller vessels. So far, researchers have been able to make simple blood-vessel structures but not more complex vasculatures that could nourish solid organs.

Bioprinters could potentially construct a series of channels into each layer of cells, and these channels might be used to supply blood to tissue, says Dr Boland, who is working on the problem. His approach is to create hollow tubes from fibrin, a protein involved in blood clotting, surrounded by fat cells. On their inside, the tubes entrap endothelial cells, a type of cell that naturally forms blood vessels. The tubes serve as scaffolds for the cells, which—after being printed—go through a growing phase in an incubator. The structure is then implanted in mice and, if all goes well, connects up and integrates with surrounding tissues. If this approach works out, it could also prove useful for Dr Boland’s company, TeVido BioDevices, which aims to develop custom bioprinted implants and grafts for breast-cancer patients made from their own fat cells.

Organovo is licensing Dr Boland’s original cell-printing patent and has incorporated inkjet technology into its current systems (though the company will not disclose whether it plans to use it to help manufacture liver tissues). While Dr Forgacs’s extrusion process creates larger cell structures very quickly, one important feature of the inkjet-printing approach is its high resolution. It can be used to add detail and to apply thin layers of cells and patterns within layers, says Mr Murphy.

Several laboratories are currently working on developing bioprinters that could print skin cells directly onto wounds and burn injuries. At Wake Forest, researchers use a printer in conjunction with a laser to scan the size and depth of an injury. It produces a topological 3D map of the wound, which is used to determine how much material to deposit at any one spot, explains John Jackson, a member of Wake Forest’s skin-printing team.

Although the majority of bioprinters at Wake Forest are inkjet based, the researchers opted for a pressurised version. This is because of the difficulty of getting cells through the inkjet nozzle. “You get a lot of clogs,” says Dr Jackson. With the system they have chosen the researchers can change nozzle sizes, and the machine can print up to eight different types of cell. Recent studies on animals have shown that it is successful in printing precise layers of cells and cell types onto wounds. The process takes about 20-30 minutes for a wound that is around 10cm in length and width and up to 1cm deep.

The current treatment for burn patients is to take skin grafts from other areas of their body and transplant them onto the wounds. But the supply of skin from the body is limited, and the graft has to be prepared for transplantation. So, asks Dr Atala, why not save a step and print skin cells directly onto the patient? “The patient itself is the best incubator,” he believes. This process might also work for people with diabetes and for the elderly, whose wounds often do not heal well. Dr Jackson hopes, if things go according to plan, that the skin printer could be used in clinical trials within three or four years.

Dr Forgacs’s latest project does not involve bioprinting for medical purposes, but a simplified printing process to create meat for people to eat. When Organovo went public in 2012, he decided to leave the board (though he is still a consultant for the company) and devote more time to being chief scientific officer of Modern Meadow, a startup which he co-founded in 2011. As producing biomaterials for human consumption will probably involve lots of regulatory testing before any products can be brought to market, the company will initially concentrate on making leather (although not with a bioprinting process, but with some other form of biofabrication, says Dr Forgacs). Leather-goods manufacturers will be intrigued to see what he comes up with.

Dr Forgacs is hopeful that scientists will be able to build major organs eventually, although he does not believe they will ever be able to recreate a heart or kidney in the same minute detail as those organs exist inside the body. Instead he suggests researchers should look at building biological structures that function the same way. These will not look like the organs people have, he says, but they will be able to perform some of the same functions.

Mini organs

Organovo is conducting animal tests with structures that are not organs but smaller, patch-sized tissues that it can build. These structures could work like miniature organs and assist damaged tissue to function as normally as possible. For example, a heart-muscle patch could help repair the heart after a myocardial infarction. Or a patch could be used to bypass a blocked blood vessel. These are early-stage studies and no results have yet been disclosed. The company will evaluate a number of tissues which might be bioprinted as patches or mini organs, and then choose one or two with which it may proceed to clinical trials, possibly within the next five years, says Organovo’s Mr Murphy.

Ibrahim Ozbolat from the University of Iowa co-wrote a review of bioprinting and organ fabrication last year. He believes miniature organs are an important step towards creating fully functional organs, as they may be able to perform the most vital functions, such as the secretion of insulin to help the pancreas regulate glucose levels. The mini organs or patches may not cure patients, but could improve their quality of life. “The good news is the field is growing tremendously,” says Dr Boland. The arrival of the first products on the market will encourage more people to start working on bioprinting, and thus further breakthroughs.

<<<

Organovo - AACR update -

http://biz.yahoo.com/e/140410/onvo8-k.html

>>> 10-Apr-2014

Regulation FD Disclosure

Item 7.01 Regulation FD Disclosure

On April 10, 2014, Organovo Holdings, Inc. (the "Company") released the following information to update investors on the results of its initial study of 3D breast tissues generated with its NovoGen MMX Bioprinter? in breast cancer models. The Company presented these results at the annual meeting of the American Association for Cancer Research (AACR) held on April 5-9, 2014 in San Diego, California.

Results from the Company's initial study showed the following:

? The Company's NovoGen MMX Bioprinter technology can successfully fabricate 3D breast tissues consisting of cancer cells, fibrous stroma, adipose tissue, and microvasculature on a reproducible basis.

? 3D bioprinting enables compartmentalization of the breast tissue, with tumor epithelium controllably surrounded by stromal tissue.

? Histologic and metabolic (Alamar Blue and ATP) measurements highlighted a consistency in printing from construct to construct.

? The Company's experiments involving the delivery of fluorescently-tagged drugs to its 3D breast tissues indicate:

? Some drugs like methotrexate, which is small and hydrophilic, can fully penetrate our 3D bioprinted tissues, allowing us to assess the effects of drugs throughout the full thickness of the tissue.

? Other drugs, like paclitaxel, which is large and lipophilic, which are known to have trouble penetrating solid tumors due to dense stroma presence, charge, or other factors, are similarly modeled in the Company's 3D breast tissues.

? The Company's head-to-head comparisons of common anti-cancer drugs (cisplatin, methotrexate, paclitaxel) in MCF-7 2D tissue cultures versus the MCF-7-containing 3D tissues developed by the Company showed clear, differential responses:

? Total 3D tissue viability was decreased in response to cisplatin, but histologic analyses of the cisplatin-treated tissues showed that the bulk of cell death occurred in the stromal fraction, with the tumor epithelial cells demonstrating resistance to the drug.

? In contrast, the 3D tissue system was resistant to methotrexate-mediated toxicity compared to the 2D tissue culture system. Based on studies with labeled compound, this cannot be attributed simply to lack of penetration.

These early results from the Company's initial study confirm that the 2D culture systems were not effective in modeling drug responses in complex, multi-cellular tissue systems, like breast cancer. Furthermore, these early results suggest that utilizing 3D tissues may enable researchers to make compartment-specific assessments (i.e., epithelium, stroma, vasculature) of drug response - something that is not currently possible outside of in vivo models to date.

As previously announced, on April 10, 2014, Keith Murphy, the Company's Chairman and Chief Executive Officer , will be participating in a live webcast presentation to investors via RetailInvestorConferences.com. The presentation will take place at 12:00 PM ET, and investors may access the presentation at www.retailinvestorconferences.com > click on red "register / watch event now" button. A copy of the presentation slides will be available on the Company's website under the "Investors" tab. In addition, investors may access an on-demand archive of the presentation at www.retailinvestorconferences.com for at least 90 days.

<<<

>>> Organovo Holdings Inc Founder: We May Not Print Organs, but That Won't Matter

By Brian Stoffel

April 9, 2014

http://www.fool.com/investing/general/2014/04/09/organovo-holdings-inc-founder-we-may-not-print-org.aspx

Imagine the ability to create a fully functioning human organ using a 3-D bioprinter.

Even though it's not a key piece of the technology Organovo Holdings Inc (NYSEMKT: ONVO ) is counting on for revenue any time soon, it's still how many investors -- myself included -- kick off an introduction to Organovo's long-term aspirations.

Recently, however, some short-sellers have begun circulating news that Organovo's scientific founder, Dr. Gabor Forgacs of the University of Missouri Columbia, has made it clear he doesn't think the days of printing organs will ever come.

That news was confirmed earlier this week, when Forgacs penned a letter with Organovo CEO Keith Murphy stating: "Will we be able to bioprint copies of the organs we carry in our body? Perhaps not due to a number of factors in addition to the technology hurdles."

Guess what? It shouldn't matter at all

Of course, with an admission like that, it's easy to see why investors in the company might feel like its time to bail on its stock. But a careful read of the rest of the letter shows why any short thesis that revolves around Forgacs' belief or involvement in the company is patently false.

Forgacs follows up the quote above by clearly stating (emphasis added): "I believe that Organovo's technology can eventually be used to build complex organ structures from the patient's own cells, which function as well as if not better than the original ones, even if differing in the details."

In other words: Everyone needs to take a deep breath and put this all in context. Forgacs makes it clear he still "actively participate[s]" in Organovo's work, and that he "remain[s] one of the company's largest shareholders."

For those who do believe in the long-term prospects for Organovo, the matter of whether or not bioprinted organs are on the horizon is just noise that it'd be better to ignore. It would be far more productive to spend time focusing on the performance of the company's 3-D liver assays, which are set to become available sometime before or by December 2014.

As it is, drug companies spend billions of dollars on developing drugs every year that will eventually fail in clinical trials due to toxicities. Liver toxicities are foremost among the culprits.

While there are other liver products on the market for testing now, Organovo says that no one can offer the types of samples it has because Organovo's so closely mimic native cell behavior, and because those cells can now last for over 40 days, allowing a broad range of toxicities enough time to develop.

If these liver assays turn out to be as helpful as the company thinks they can be--and Organovo continues to develop other tissues with these advantages--investors will soon forget about the promise of bioprinted organs, and instead focus on the real work the technology can accomplish today.

But still, tread carefully

Even though I myself am a shareholder, it's always worth noting that this is a very risky stock. Organovo has never in its history brought in any significant amount of revenue from product sales. Additionally, it is valued today at roughly $600 million -- a ridiculously high number given traditional metrics.

That's why shares of the company account for less than 1% of my overall holdings, and will continue to until it can prove that its products really can revolutionize how drug companies go about testing their new treatments.

Say goodbye to 'Made-In-China'

For the first time since the early days of this country, we’re in a position to dominate the global manufacturing landscape thanks to a single, revolutionary technology: 3D printing. Although this sounds like something out of a science fiction novel, the success of 3D printing is already a foregone conclusion to many manufacturers around the world. The trick now is to identify the companies -- and thereby the stocks -- that will prevail in the battle for market share.

<<<

Organovo -- >>> AACR Presentation Abstract

>>> Abstract Number: 2034

Presentation Title: Development of 3D bioprinted human breast cancer for in vitro drug screening

Presentation Time: Monday, Apr 07, 2014, 1:00 PM - 5:00 PM

Location: Hall A-E, Poster Section 5

Poster Board Number: 18

Author Block: Shelby M. King, Sharon C. Presnell, Deborah G. Nguyen. Organovo, Inc., San Diego, CA

Abstract Body: As breast cancer is a disease of multiple cell types in which the growth, invasion, and metastasis of epithelial carcinomas is heavily influenced by the surrounding cell types, screening of anti-cancer compounds using cancer cell lines grown in 2D often overestimates drug potency. Regulatory agencies are currently seeking improved preclinical oncology models to overcome hurdles to efficient drug development, including bridging the gap between the use of 2D cell lines and 3D animal models. One way to more accurately determine the effects of anti-cancer compounds is through the use of cancer tissue models that incorporate stromal cells of the tumor microenvironment. Breast stroma, composed of fibroblasts, endothelial cells, and adipocytes, plays a key role in the process of carcinogenesis and metastasis. These cell types secrete extracellular matrix, growth factors, and hormones that affect how therapeutic agents access and target cancer cells. We have used Organovo’s NovoGen BioprintingTM Platform to develop a model of human breast cancer in which a core of breast cancer cells is surrounded by a physiologically-relevant stromal milieu consisting of adipocytes, mammary fibroblasts, and endothelial cells. This system has several advantages over current screening tools, including the ability to simultaneously measure the effects of small molecules on cancer cells as well as different cell types in the breast microenvironment. Histological analyses of bioprinted neotissues demonstrated that they were stable and viable for at least 14 days in culture and characterized by interaction between stroma and carcinoma compartments. Incorporation of endothelial cells into the 3D neotissue led to the formation of robust microvascular networks. Breast cancer neotissues were fabricated directly into multi-well plates and used to establish biological response profiles to the standard chemotherapeutic agents cisplatin, paclitaxel, methotrexate, and tamoxifen. The cytotoxic effects of chemotherapeutic drugs on specific cell types within the neotissues were assessed biochemically and histologically. he response of the 3D breast cancer neotissues to chemotherapeutic gents was compared to the response of 2D breast cancer cell lines to determine he relative efficacy of compounds in 2D versus 3D. This model can be used to screen new anti-cancer therapeutics in the context of the in vivo-like microenvironment, leading to enhanced efficiency and accuracy of the drug development process.

<<<

>>> Cornell Professor Develops Technique for 3D Printing a Human Ear

February 24, 2013

http://on3dprinting.com/2013/02/24/cornell-professor-develops-technique-for-3d-printing-a-human-ear/

Cornell Prof 3D Prints Human Ear

3D printing organs and stem cells is currently being researched and may become a reality someday. What about 3D printing an ear using material to synthesize human cartilage?

Lawrence Bonassar, associate professor of biomedical engineering at Cornell University, has been working to solve this problem by developing a “living ink” that can be used to 3D print the cartilage for a human ear. His research was published in the journal PLoS One and featured on NPR.

“The ear is really remarkable from a mechanical perspective,” says Lawrence Bonassar, an associate professor of biomedical engineering at Cornell University who has been working with a group to develop a better replacement ear.

To make the ear, Bonassar and his colleagues scanned the ears of his twin daughters, who were 5 at the time. They used a 3-D printer to build a plastic mold based on the scan. Those printers, similar to a home inkjet, lately have also been adapted to experiment with making chocolate, guns, and even kidneys.

They then injected a soup of collagen, living cartilage cells, and culture medium. The soup congeals “like Jell-O,” Bonassar tells Shots. “All this happens quickly. You inject the mold, and in 15 minutes you have an ear ready to go.”

Well, not exactly. What they have is an ear-shaped chunk of cells that would have to be tucked under the skin on the side of the head by a plastic surgeon before it could become an ear.

To test whether their ear-mold would become living, useful ear cartilage, the researchers implanted samples under the skin on the back of laboratory rats. In three months, cartilage cells took over the collagen, making for a solid-yet-flexible chunk of cartilage that retained its precise shape and size.

Bonassar thinks this technology can be used in humans in 5 years, with any luck

<<<

TeVido BioDevices -

http://tevidobiodevices.com/

>>> TeVido BioDevices is an early-stage life sciences/biotech company using 3D bio-printing of a woman’s own living cells – to build custom grafts for breast cancer reconstruction. Our first product is targeted to improve nipple reconstruction and later fill lumpectomies.