Tuesday, April 24, 2012 11:44:42 AM

WTH??? Consider, for example, the following variables and issues NOT considered in the computations, figures, data, and conclusions of the vast amount of misinformation out there about the REAL problems facing MMTE.

RELEVANT BACKGROUND INFORMATION

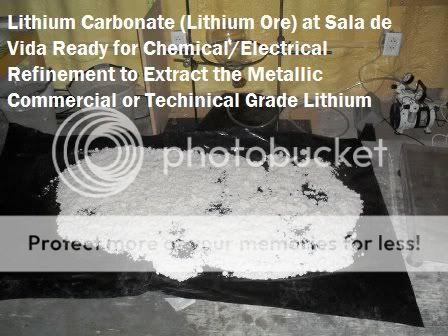

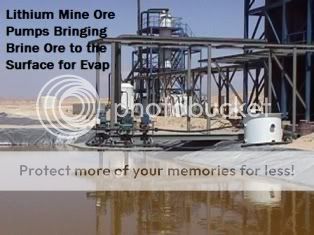

Lithium is the lightest of all the worlds metals. Lithium used in commercial and technical products are extracted from raw materials by mining operations from tiny to massive. The fundamental mining processes used by modern lithium miners – whether on a very small or very large scale – involve pumping subsurface lithium-infused brine waters into evaporation ponds, which produce raw lithium ore (i.e., a cream or white colored salty powder) left by evaporating the brine water. Such lithium mines are plentiful on the salars (high, remote, barren desert plains) of Chile & Argentina, which currently boast some of the most profitable lithium mining and refining operations. “Lithium enriched brines are mainly harvested and processed in Argentina and Chile where they are partly exploited as a by-product of potash production.” DORFNER Analysenzentrum und Anlagenplanungsgesellschaft, Strategic Minerals, “Lithium” (2011) @ http://www.anzaplan.com/strategic-minerals . Hence, many start-up and established companies now engage in a sort of “Lithium Rush” to stake their claims and seek for that “pay dirt” in a manner reminiscent of the 1849 California Gold Rush and the subsequent Klondike Gold Rush.

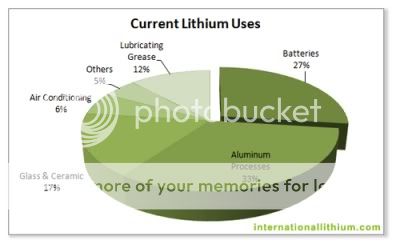

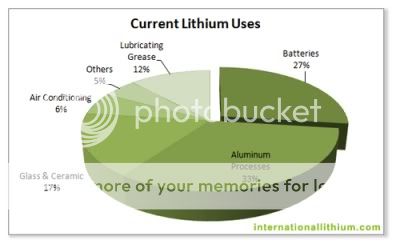

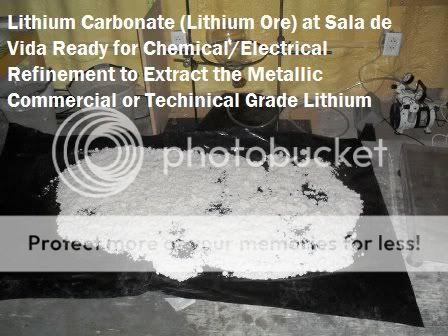

The primary use of lithium involves purified lithium’s excellent ability to act as a pure, metallic, conductive medium in sophisticated commercial and technical products/technologies (copper, silver, and gold are used for similar purposes, but are too heavy for the technologies requiring lithium). Thus, from “mom ‘n pop” (i.e., small, start-up) lithium mining operations to massive corporate operations, producing pure lithium metals from that mass of evaporated, powdery white, "lithium ore" requires a considerable amount of work. First, mining operations must sift and purify the lithium ore by removing potash, salt, etc., until only lithium carbonate and lithium hydroxide compounds remain. Thereafter, lithium miners and/or refiners – both small and large – must refine the lithium carbonate/hydroxide compounds through various industrial, chemical, and hydrometallurgical processes to separate or “release” pure lithium chloride and spodumene from the carbonate/hydroxide powdery compounds. See, e.g., id. (Of note, in a way this process is quite similar to the general processes used by both the small-time and large conglomerate hard rock mining operations of the 19th century, e.g., involving the use of stamp mills, gold dust-mercury adherence, and subsequent separation of the gold from the mercury. See, e.g., W. Feller, “Ore Milling & Processing,” (2010) @ http://digital-desert.com/gold-mining/stamp-mill.html .) Finally, when only a lithium chloride/spodumene compound remain, the refinery then "extracts" the pure metal lithium from the chloride/spodumene compound by melting the compound and then passing a specific electric charge through the molten “compound soup,” which charge pulls the pure, final commercial-grade lithium metal off of or away from any non-elemental particles within the molten lithium chloride/spodumne compound. Further metallic refining purifies commercial-grade lithium (compare, e.g., 18K gold) into technical-grade lithium (compare, e.g., 24K gold). See, e.g., DORFNER Analysenzentrum und Anlagenplanungsgesellschaft, Strategic Minerals, “Lithium” (2011), supra @ http://www.anzaplan.com/strategic-minerals

FROM GROUND TO GRADE

As shown below and as shown in the various non-iHub cited authorities herein, a startup lithium mining operation on the Chilean salars, like MMTE, must successfully certain mandatory tasks involved in moving the trace lithium particles in the ground or brine water through the above process in order to produce marketable, commercial or technical grade lithium. Startups like MMTE either must have (1) adequate on-hand, private or massive publicly funded capital or (2) merger/joint venture-infused capital required to design, map, mobilize, coordinate and/or construct the many aspects of a new mining operation – from tiny to massive (e.g., geologic test teams, mine operations managers, qualified/experienced laborers, drilling rigs, pumps, evaporation ponds, ore harvesters, separation/processing plants, refineries, transportation systems, etc.). These required tasks, talent, equipment, and structures must exist so that some day in the future the new company, merged entities, or joint venture might bring trace amounts of lithium from the high plains brine water of Chile – some 5,500 miles from Silicon Valley – all the way to refined and purified commercial/technical grade lithium for purchase by end users.

Accordingly, such formidable, challenging, and expensive tasks facing MMTE, an entity merged with MMTE, or a joint venture involving MMTE include, e.g., at least the following eight mandatory phases:

(1) Find and bring-into a rather remote and arid environment a solid number of well-trained, experienced lithium miners, professionals, refining experts, and laborers (e.g., geologists, geotechnicians, hydrologists, hydrotechnicians, chemists, chemical engineers, structural engineers, civil engineers, electrical engineers, environmental engineers, climatologist(s), project manager(s), drafters, civil/structural designers, IT supervisor, IT technicians, mine engineers, surveyors, operations managers, mine operations technicians, controllers, auditors, procurement specialists, drillers, welders, machinists, fitters, plumbers, repair crews, earthwork supervisors, mine superintendents, miners, milling supervisors, millers, metallurgists, refining supervisors, refiners, production technicians, transporters, human resource coordinators, safety compliance and loss prevention officers, quality control officers, contract managers, emergency healthcare providers, repair crews, internal sales & market representative/liaison, inventory manager(s), secretaries, receptionist(s), internal Chilean legal counsel, internal Chilean lobbyist/PR officer, maintenance technicians, and various general laborers serving the above trades;

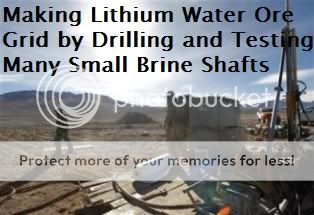

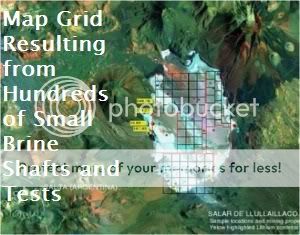

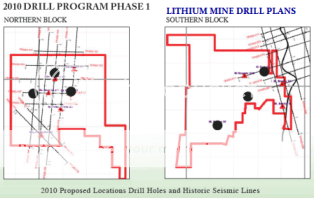

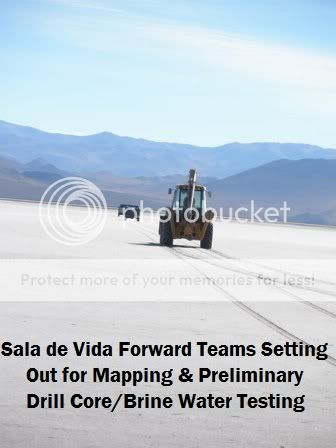

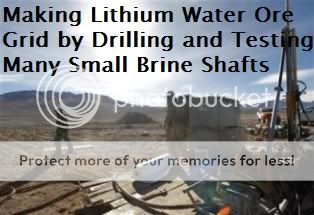

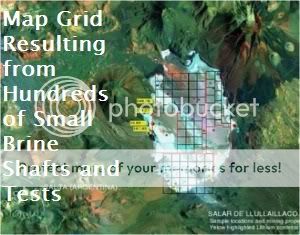

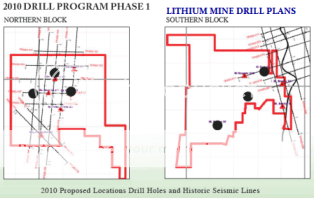

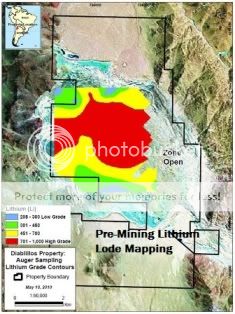

(2) Survey and create a detailed surface mine site division map while concurrently testing brine densities to prepare for lode analysis;

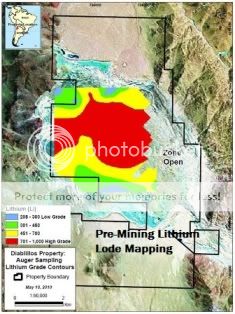

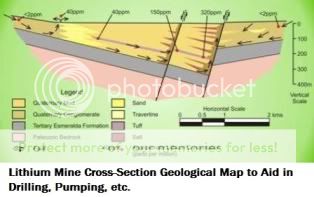

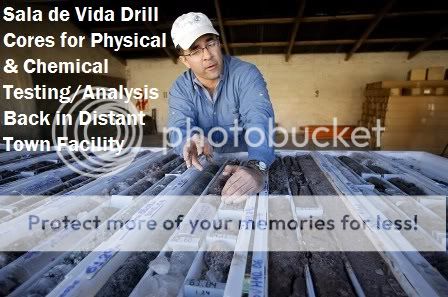

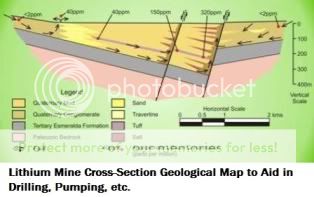

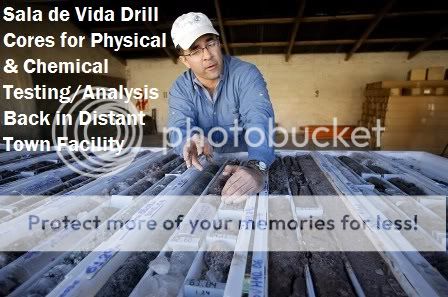

(3) Complete extensive geotechnical and chemical testing to map the lithium-rich mine site lodes in preparation for targeted, efficient, long-term lithium ore extraction (“ore” meaning both the brine water and the cream-colored, powdery, mineral compounds left after evaporating the brine water);

(4) Arrange for the transportation and training of crew and equipment from where ever they are now (e.g., in large, coastal or inland Chilean cities) to the remote mining sites deep in the Chilean deserts;

(5) Start and continue extracting mass amounts of lithium ore in preparation for evaporation ponds and subsequent transport for processing and refining;

(6) Transport the many, many tons of lithium ore to the concentrators, processing plants, refineries, etc., required to extract, isolate, refine, and purify commercial/technical grade lithium (furthermore, if such processing, refining, product shipment preparation facilities, infra, product storage facilities are not already available, MMTE or its partners will have to pay for and build such facilities… no matter how small the mining operation is because the locations are remote, inherently requiring a significant degree of self-sufficiency);

[

[

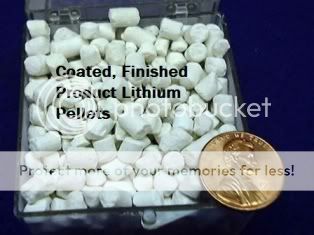

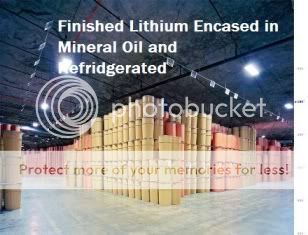

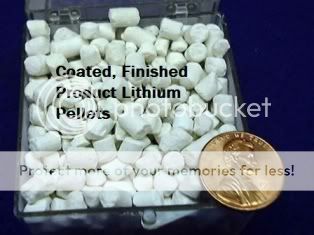

(7) Finalize commercial/technical grade lithium metal sheets, rods, pellets, etc. in preparation for storage or shipment. Then, prepare the lithium for transport to the end-user or growing commercial market by packaging it and preparing it for shipment to and purchase by end users, e.g., encasing it in protective mineral oil, packaging it in chemically compatible protective material, or covering the pellets with lithium hydroxide - all to prevent the rapid tarnishing and/or decaying effects that refined lithium suffers in Earth's open atmosphere;

(8) Dispose of waste products responsibly, legally, and as efficiently as possible.

See, e.g., Associated Newspapers, "In Search of Lithium: The Battle for the 3rd Element," (April 2009) @ http://www.dailymail.co.uk/home/moslive/article-1166387/In-search-Lithium-The-battle-3rd-element.html ; SQM, "Lithium Production Process" (2011) @ http://www.sqm.com/aspx/about/ProductionProcess.aspx ; Rio Tino Mining Company, "Surface Mining Virtual Tour" (2011) @ http://www.kennecott.com/visitors-center/take-a-virtual-tour .

BIRTH AND GROWTH OF A SMALL-SCALE, START-UP LITHIUM MINING OPERATION

So what does it really take to move a small lithium-mining project from ground to grade? The following exemplifies what is required of a small, start-up lithium mining company regarding time, costs, etc., to move sufficient lithium from the ground to commercial or technical grade in a profitable manner.

Salita de Vida Lithium Mine Operation

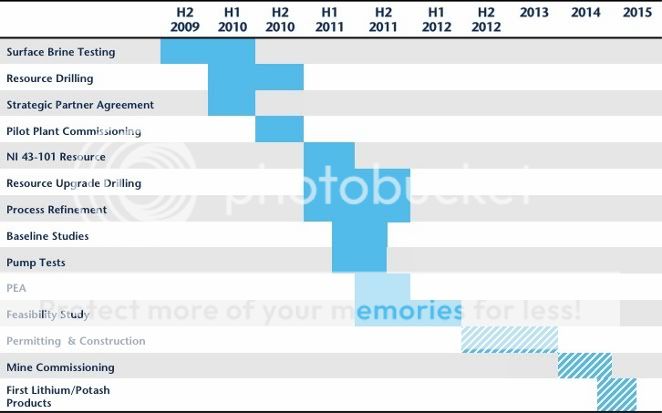

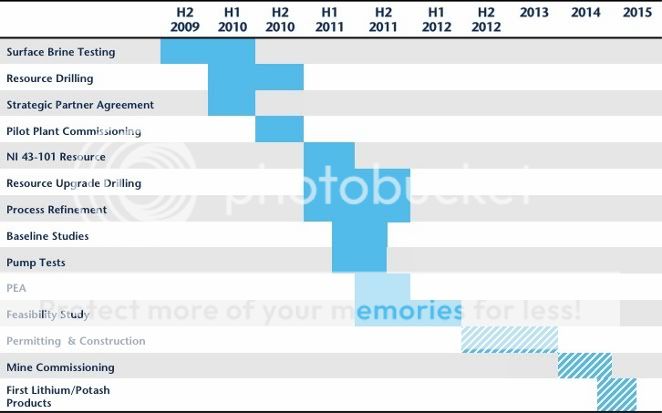

Salita de Vida (or Sal de Vida), a developmental and very small lithium mining project, recently emerged as one of the highest grade undeveloped lithium brine deposits in Chile with significant expansion potential. “ The systematic evaluation of the Sal de Vida Brine Project continues according to the $15 million work program approved by the Company and its… partners….. The Company expects to deliver a [resulting] preliminary economic assessment (“PEA”) in the third quarter of 2011 .” The Sal de Vida PEA will model the economics of a small, conventional evaporation recovery circuit for “both lithium and potash, using data collected from the drilling programs, pumping tests, evaporation circuit and pilot plant work, and other engineering and process studies that are underway or already completed. The PEA will be followed by the feasibility study by the middle of 2012, and if positive, progress to low-cost commercial production of lithium and potash in 2014. ”

Yes – that’s about three years from the preliminary project assessment phase – which satellite photo evidence shows that MMTE has yet to begin on any of its purported lithium properties – to the point of actually beginning to produce refined, marketable lithium!

Salita de Vida Lithium Mining Project Timeline

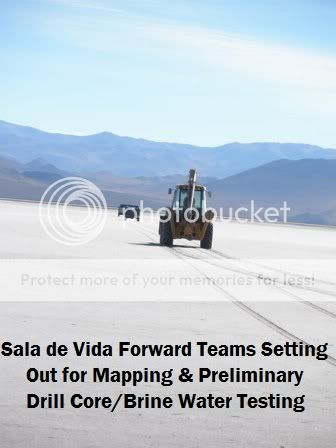

See, e.g., “Sala de Vida” (2011) @ http://www.lithium1.com/s/SaldeVida.asp ; Montgomery & Associates, Completed Lithium Resource Estimate Report for Sala de Vida Project @ http://www.lithium1.com/i/pdf/Technical_Report_43-101_FINAL_R-April-2011.pdf ; see also Sala de Vida Project Photos:

SO WHERE IN THE TIMELINE TO PROFITABILITY IS MMTE and/or MMTE+Partners NOW?

Currently, MMTE reports that it continues to acquire lithium mining "land" and extraction "rights." Unless MMTE honestly believes that the mining concessions it has are going to rapidly appreciate for a profitable sale or lease, the only way to make money of the concessions will requiring mining it at some point.

Further, MMTE’s concessions likely prove moderately lithium-enriched at the best. Indeed, the world's most lithium-rich geographical deposits, typically found in the arid, salty flats known as "salars," do NOT include MMTE's claims/concession to small portions of Chilean salars (e.g., Salar de Maricunga, Salar del Laco, and Salar de Pujsa). Indeed, the worlds lithium-richest and premiere lithium mines/deposits exclude MMTE’s concessions, but include: (1) Salar de Hombre Muerto; (2) Salar de Rincon; (3) Cauchari, (4) Olaroz, (5) Salar de Uyuni, (6) Salar de Atecama, (7) Taijanier Lake, (8) Zhabuye, and (9) Silver Peak.

See, e.g., id.; MMTE Website @ http://www.mammothenergygroup.com/projects.html ; Signum Box, "Salar de Maricunga: Project Review," p.5, tab. 3 (June 2011) @ http://www.li3energy.com/projects/signumBOX/IVG-LIEGsignumBOX2011.pdf ; Lithium Investing News, "World Class Deposit" @ http://lithiuminvestingnews.com/investing-in-lithium/lithium-world-class-deposit ; R.K. Evans, An Abundance of Lithium II @ http://www.worldlithium.com/AN_ABUNDANCE_OF_LITHIUM_-_Part_2.html ; New World Resource Corp., "Projects About Lithium," @ http://www.newworldresource.com/s/AboutLithium.asp .

BRINGING LITHIUM FROM GROUND TO GRADE IS BOTH TOUGH & EXPENSIVE

Contrary to much of the investment-babble spouted by MMTE’s powers that be, "The extraction of lithium is a very complex process, requiring many specialized machines and equipment." Ciros Machinery Corporation, "Lithium Processing Equipment," 2011 (emphasis added). Furthermore, "The salars are large, dry lakebeds where the brines [e.g., brine water 'ores'] containing only trace amounts of lithium) are located under . . . layered, crusted salt deposits. These (lithium mining) areas are remote and inhospitable. (Accordingly, in order to locate, extract the brine pool ore from underground for evaporation into powder ore, followed by transportation of the ore and the lithium processing/refinement processes in such bleak, barren mining lands AND still make a profit) requires a considerable investment in research, exploration, mobilization, and transportation of [highly trained] personnel and materials." FMC Lithium, "Lithium History" @ www.fmclithium.com/Home/LithiumHistory.aspx (emphasis added). MMTE, even with a merging entity or JV partner, therefore faces formidable industry-entry costs similar to, say, a start-up company just trying to get a foot in the door of the oil exploration/extraction industry.

Moreover, even small mining operations require relatively expensive and environmentally controversial lithium mining equipment and facilities (e.g., drilling rigs, commercial grade brine water pumps, miles of piping, giant evaporators, thousands of acres of solar evaporation basins, raw lithium salt harvest machinery, concentrator facilities, condensers, complex canal systems, grinding mills, ball mills, processing facilities, potash recovery facilities, refineries, lithium chemical refinement plants, lithium mineral refinement plants, storage tanks, a means of ore/brine water and product transportation, tanker trucks, buses, waste processing facilities, etc.). See, e.g., id.; see also "The Trouble with Lithium II: Under the Microscope," supra, pp. 1-5, 17, 33, 46 ; TRU GROUP, "Tru Lithium," @ http://trugroup.com/Lithium-Battery.html . Such systems, mills, equipment, and processing facilities allow the production of lithium from minerals in brine water lithium "ore" (e.g., underground brine pools, mineral springs) or regolith ore (e.g., crusted salt layers with tiny lithium deposits). Without such equipment, facilities, and the professionals required to operate them – profiting off lithium land concessions proves extraordinarily rare.

Indeed, even if the owner of the concessions (e.g., MMTE) manages to bring in another company to do all the “dirty work” of mining, processing, refining, and transporting the market-grade lithium, the company completing the “dirty work” implicitly earns almost all the profit! The “dirty work,” which MMTE is in no place to perform, is what brings the vast majority of the value to the almost worthless trace amounts of lithium floating around in the extraordinarily isolated and evasive groundwater of the Chilean high deserts to highly profitable commercial/technical grade, purified, refined, marketable, and profitable lithium metals. The “owner” of the concessions only owns the nominal, “static” value of the trace lithium amounts 5,500 miles away from Silicon Valley in the middle of some damn desert in the middle of nowhere. The owners, human resource coordinators, and operators of all that expensive and environmentally controversial deep desert lithium mining equipment and facilities incur massive risks and expenses to make ready the trace lithium particles under the high desert floor for purchase as commercial/technical grade by the end-users. THOSE are the entities that make the money, not the “absentee” landlord such as MMTE seems it will become, as it has done virtually nothing to engage in the above eight phases required of a successful mining company. MMTE will likely never mine one ounce of lithium; some other company will do it and make the vast lion’s share of the profits. See, e.g., id.; see also J.A. Ober, United States Geological Survey,"Lithium," 77–78 (Aug. 2007).

THE VALUE IN THE GROUND???

The Chilean high deserts are vast, remote, and inhospitable geographic regions dotted with sporadic salt beds or “salars.” Under some of these salars lie pools of brine water that contain anywhere from faint to fairly rich concentrations of lithium ore. From these salars and brine waters, experienced and well-funded mining exploration and development companies painstakingly prospect for the most lithium-ore-rich lodes to extract, transport, process, refine, and sell for high dollar to end users such as lithium-ion battery manufacturers.

Some say that MMTE's value is based in the lithium in the ground… that all of the other, above aspects of exploration, mining, evaporation, harvesting, processing, refining, transporting, selling, etc., mean nothing. A more ludicrous statement one would find hard to make. As discussed, the owner of lithium mining concessions own only the scant value of the trace lithium amounts floating in the groundwater in one of the world’s most barren and isolated regions. The value is just not there, especially where other regions prove far more lithium-rich than the concessions obtained by MMTE.

First, unless MMTE can find an entity crazy enough to merge or create a joint venture with the devalued, diluted, forlorn, newcomer MMTE to mine & refine lithium (eventually) the relatively tiny land acquisitions/mining concessions MMTE required some sort of an ownership interest in – or some such other miracle happens – I believe MMTE will have mislead investors, financiers, financial institutions, and perhaps governments. MMTE will thus, IMHO, find itself in a world of hurt sooner than later.

Second, The world's most lithium-rich geographical salars do NOT include MMTE's purported "concessions" to relatively small salar portions deep within Chile's most inhosptiable region (e.g., Salar de Maricunga, Salar del Laco, Salar de Pujsa). Indeed, the world's primary/vastly superior lithium-rich and lithium-producing salars - among which one will fine ZERO (0) MMTE salar concessions - include: (1) Salar de Hombre Muerto; (2) Salar de Rincon; (3) Cauchari, (4) Olaroz, (5) Salar de Uyuni, (6) Salar de Atecama, (7) Taijanier Lake, (8) Zhabuye, and (9) Silver Peak. MMTE's concessions are not among the world's approximate top ten lithium salar land masses, and as far as lithium-producing salars go, there really are not very many of them in toto anywhere on the planent. See, e.g., MMTE Website @ http://www.mammoth-energy.com/projects.php ; Signum Box, "Salar de Maricunga: Project Review," p.5, tab. 3 (June 2011) @ http://www.li3energy.com/projects/signumBOX/IVG-LIEGsignumBOX2011.pdf ; Lithium Investing News, "World Class Deposit" @ http://lithiuminvestingnews.com/investing-in-lithium/lithium-world-class-deposit ; R.K. Evans, An Abundance of Lithium II @ http://www.worldlithium.com/AN_ABUNDANCE_OF_LITHIUM_-_Part_2.html ; New World Resource Corp., "Projects About Lithium," @ http://www.newworldresource.com/s/AboutLithium.asp .

Third, based on the press releases and, inter alia, the above data (including all cited information/links), MMTE appears far from establishing even the most basic resources required to mobilize and initiate a successful precious metal mining and refining operation. Moreover, without mammoth dilution and/or a reverse split, MMTE will almost certainly find itself unable to finance the colossal industry entry costs inherent to precious metal mining - small Brine Mining operations included. Further, where MMTE is nothing short of a financial train wreck and where MMTE's purported salar land ownership interests are NOT found among the very few, lithium-rich salars on the planet, one would find it rather unlikely that any truly viable or reputable mining company might want to enter a joint venture or merge with the cash-strapped, struggling, heavily O/S diluted, forlorn penny stock, MMTE.

Simply put, MMTE bought comparatively crappy salar concessions because that is all it could afford, even after selling so many shares to the 'investors' that are the so-called MMTE common shareholders, i.e., us! Value in the ground? Not so much!

SUMMARY

Without question, the above evidence and concordantly cited authority sources evidence the cold, hard fact that MMTE is a long way from selling its concessions, entering into a JV, producing any profit, or even a longer way from delivering any significant amount of lithium for purchase by end users. Either in finding a merger or JV candidate or going it alone, MMTE faces a competitive, potentially expensive, and uphill battle that simple common sense increasingly indicates MMTE proves unlikely to win.

RELEVANT BACKGROUND INFORMATION

Lithium is the lightest of all the worlds metals. Lithium used in commercial and technical products are extracted from raw materials by mining operations from tiny to massive. The fundamental mining processes used by modern lithium miners – whether on a very small or very large scale – involve pumping subsurface lithium-infused brine waters into evaporation ponds, which produce raw lithium ore (i.e., a cream or white colored salty powder) left by evaporating the brine water. Such lithium mines are plentiful on the salars (high, remote, barren desert plains) of Chile & Argentina, which currently boast some of the most profitable lithium mining and refining operations. “Lithium enriched brines are mainly harvested and processed in Argentina and Chile where they are partly exploited as a by-product of potash production.” DORFNER Analysenzentrum und Anlagenplanungsgesellschaft, Strategic Minerals, “Lithium” (2011) @ http://www.anzaplan.com/strategic-minerals . Hence, many start-up and established companies now engage in a sort of “Lithium Rush” to stake their claims and seek for that “pay dirt” in a manner reminiscent of the 1849 California Gold Rush and the subsequent Klondike Gold Rush.

The primary use of lithium involves purified lithium’s excellent ability to act as a pure, metallic, conductive medium in sophisticated commercial and technical products/technologies (copper, silver, and gold are used for similar purposes, but are too heavy for the technologies requiring lithium). Thus, from “mom ‘n pop” (i.e., small, start-up) lithium mining operations to massive corporate operations, producing pure lithium metals from that mass of evaporated, powdery white, "lithium ore" requires a considerable amount of work. First, mining operations must sift and purify the lithium ore by removing potash, salt, etc., until only lithium carbonate and lithium hydroxide compounds remain. Thereafter, lithium miners and/or refiners – both small and large – must refine the lithium carbonate/hydroxide compounds through various industrial, chemical, and hydrometallurgical processes to separate or “release” pure lithium chloride and spodumene from the carbonate/hydroxide powdery compounds. See, e.g., id. (Of note, in a way this process is quite similar to the general processes used by both the small-time and large conglomerate hard rock mining operations of the 19th century, e.g., involving the use of stamp mills, gold dust-mercury adherence, and subsequent separation of the gold from the mercury. See, e.g., W. Feller, “Ore Milling & Processing,” (2010) @ http://digital-desert.com/gold-mining/stamp-mill.html .) Finally, when only a lithium chloride/spodumene compound remain, the refinery then "extracts" the pure metal lithium from the chloride/spodumene compound by melting the compound and then passing a specific electric charge through the molten “compound soup,” which charge pulls the pure, final commercial-grade lithium metal off of or away from any non-elemental particles within the molten lithium chloride/spodumne compound. Further metallic refining purifies commercial-grade lithium (compare, e.g., 18K gold) into technical-grade lithium (compare, e.g., 24K gold). See, e.g., DORFNER Analysenzentrum und Anlagenplanungsgesellschaft, Strategic Minerals, “Lithium” (2011), supra @ http://www.anzaplan.com/strategic-minerals

FROM GROUND TO GRADE

As shown below and as shown in the various non-iHub cited authorities herein, a startup lithium mining operation on the Chilean salars, like MMTE, must successfully certain mandatory tasks involved in moving the trace lithium particles in the ground or brine water through the above process in order to produce marketable, commercial or technical grade lithium. Startups like MMTE either must have (1) adequate on-hand, private or massive publicly funded capital or (2) merger/joint venture-infused capital required to design, map, mobilize, coordinate and/or construct the many aspects of a new mining operation – from tiny to massive (e.g., geologic test teams, mine operations managers, qualified/experienced laborers, drilling rigs, pumps, evaporation ponds, ore harvesters, separation/processing plants, refineries, transportation systems, etc.). These required tasks, talent, equipment, and structures must exist so that some day in the future the new company, merged entities, or joint venture might bring trace amounts of lithium from the high plains brine water of Chile – some 5,500 miles from Silicon Valley – all the way to refined and purified commercial/technical grade lithium for purchase by end users.

Accordingly, such formidable, challenging, and expensive tasks facing MMTE, an entity merged with MMTE, or a joint venture involving MMTE include, e.g., at least the following eight mandatory phases:

(1) Find and bring-into a rather remote and arid environment a solid number of well-trained, experienced lithium miners, professionals, refining experts, and laborers (e.g., geologists, geotechnicians, hydrologists, hydrotechnicians, chemists, chemical engineers, structural engineers, civil engineers, electrical engineers, environmental engineers, climatologist(s), project manager(s), drafters, civil/structural designers, IT supervisor, IT technicians, mine engineers, surveyors, operations managers, mine operations technicians, controllers, auditors, procurement specialists, drillers, welders, machinists, fitters, plumbers, repair crews, earthwork supervisors, mine superintendents, miners, milling supervisors, millers, metallurgists, refining supervisors, refiners, production technicians, transporters, human resource coordinators, safety compliance and loss prevention officers, quality control officers, contract managers, emergency healthcare providers, repair crews, internal sales & market representative/liaison, inventory manager(s), secretaries, receptionist(s), internal Chilean legal counsel, internal Chilean lobbyist/PR officer, maintenance technicians, and various general laborers serving the above trades;

(2) Survey and create a detailed surface mine site division map while concurrently testing brine densities to prepare for lode analysis;

(3) Complete extensive geotechnical and chemical testing to map the lithium-rich mine site lodes in preparation for targeted, efficient, long-term lithium ore extraction (“ore” meaning both the brine water and the cream-colored, powdery, mineral compounds left after evaporating the brine water);

(4) Arrange for the transportation and training of crew and equipment from where ever they are now (e.g., in large, coastal or inland Chilean cities) to the remote mining sites deep in the Chilean deserts;

(5) Start and continue extracting mass amounts of lithium ore in preparation for evaporation ponds and subsequent transport for processing and refining;

(6) Transport the many, many tons of lithium ore to the concentrators, processing plants, refineries, etc., required to extract, isolate, refine, and purify commercial/technical grade lithium (furthermore, if such processing, refining, product shipment preparation facilities, infra, product storage facilities are not already available, MMTE or its partners will have to pay for and build such facilities… no matter how small the mining operation is because the locations are remote, inherently requiring a significant degree of self-sufficiency);

[

[

(7) Finalize commercial/technical grade lithium metal sheets, rods, pellets, etc. in preparation for storage or shipment. Then, prepare the lithium for transport to the end-user or growing commercial market by packaging it and preparing it for shipment to and purchase by end users, e.g., encasing it in protective mineral oil, packaging it in chemically compatible protective material, or covering the pellets with lithium hydroxide - all to prevent the rapid tarnishing and/or decaying effects that refined lithium suffers in Earth's open atmosphere;

(8) Dispose of waste products responsibly, legally, and as efficiently as possible.

See, e.g., Associated Newspapers, "In Search of Lithium: The Battle for the 3rd Element," (April 2009) @ http://www.dailymail.co.uk/home/moslive/article-1166387/In-search-Lithium-The-battle-3rd-element.html ; SQM, "Lithium Production Process" (2011) @ http://www.sqm.com/aspx/about/ProductionProcess.aspx ; Rio Tino Mining Company, "Surface Mining Virtual Tour" (2011) @ http://www.kennecott.com/visitors-center/take-a-virtual-tour .

BIRTH AND GROWTH OF A SMALL-SCALE, START-UP LITHIUM MINING OPERATION

So what does it really take to move a small lithium-mining project from ground to grade? The following exemplifies what is required of a small, start-up lithium mining company regarding time, costs, etc., to move sufficient lithium from the ground to commercial or technical grade in a profitable manner.

Salita de Vida Lithium Mine Operation

Salita de Vida (or Sal de Vida), a developmental and very small lithium mining project, recently emerged as one of the highest grade undeveloped lithium brine deposits in Chile with significant expansion potential. “ The systematic evaluation of the Sal de Vida Brine Project continues according to the $15 million work program approved by the Company and its… partners….. The Company expects to deliver a [resulting] preliminary economic assessment (“PEA”) in the third quarter of 2011 .” The Sal de Vida PEA will model the economics of a small, conventional evaporation recovery circuit for “both lithium and potash, using data collected from the drilling programs, pumping tests, evaporation circuit and pilot plant work, and other engineering and process studies that are underway or already completed. The PEA will be followed by the feasibility study by the middle of 2012, and if positive, progress to low-cost commercial production of lithium and potash in 2014. ”

Yes – that’s about three years from the preliminary project assessment phase – which satellite photo evidence shows that MMTE has yet to begin on any of its purported lithium properties – to the point of actually beginning to produce refined, marketable lithium!

Salita de Vida Lithium Mining Project Timeline

See, e.g., “Sala de Vida” (2011) @ http://www.lithium1.com/s/SaldeVida.asp ; Montgomery & Associates, Completed Lithium Resource Estimate Report for Sala de Vida Project @ http://www.lithium1.com/i/pdf/Technical_Report_43-101_FINAL_R-April-2011.pdf ; see also Sala de Vida Project Photos:

SO WHERE IN THE TIMELINE TO PROFITABILITY IS MMTE and/or MMTE+Partners NOW?

Currently, MMTE reports that it continues to acquire lithium mining "land" and extraction "rights." Unless MMTE honestly believes that the mining concessions it has are going to rapidly appreciate for a profitable sale or lease, the only way to make money of the concessions will requiring mining it at some point.

Further, MMTE’s concessions likely prove moderately lithium-enriched at the best. Indeed, the world's most lithium-rich geographical deposits, typically found in the arid, salty flats known as "salars," do NOT include MMTE's claims/concession to small portions of Chilean salars (e.g., Salar de Maricunga, Salar del Laco, and Salar de Pujsa). Indeed, the worlds lithium-richest and premiere lithium mines/deposits exclude MMTE’s concessions, but include: (1) Salar de Hombre Muerto; (2) Salar de Rincon; (3) Cauchari, (4) Olaroz, (5) Salar de Uyuni, (6) Salar de Atecama, (7) Taijanier Lake, (8) Zhabuye, and (9) Silver Peak.

See, e.g., id.; MMTE Website @ http://www.mammothenergygroup.com/projects.html ; Signum Box, "Salar de Maricunga: Project Review," p.5, tab. 3 (June 2011) @ http://www.li3energy.com/projects/signumBOX/IVG-LIEGsignumBOX2011.pdf ; Lithium Investing News, "World Class Deposit" @ http://lithiuminvestingnews.com/investing-in-lithium/lithium-world-class-deposit ; R.K. Evans, An Abundance of Lithium II @ http://www.worldlithium.com/AN_ABUNDANCE_OF_LITHIUM_-_Part_2.html ; New World Resource Corp., "Projects About Lithium," @ http://www.newworldresource.com/s/AboutLithium.asp .

BRINGING LITHIUM FROM GROUND TO GRADE IS BOTH TOUGH & EXPENSIVE

Contrary to much of the investment-babble spouted by MMTE’s powers that be, "The extraction of lithium is a very complex process, requiring many specialized machines and equipment." Ciros Machinery Corporation, "Lithium Processing Equipment," 2011 (emphasis added). Furthermore, "The salars are large, dry lakebeds where the brines [e.g., brine water 'ores'] containing only trace amounts of lithium) are located under . . . layered, crusted salt deposits. These (lithium mining) areas are remote and inhospitable. (Accordingly, in order to locate, extract the brine pool ore from underground for evaporation into powder ore, followed by transportation of the ore and the lithium processing/refinement processes in such bleak, barren mining lands AND still make a profit) requires a considerable investment in research, exploration, mobilization, and transportation of [highly trained] personnel and materials." FMC Lithium, "Lithium History" @ www.fmclithium.com/Home/LithiumHistory.aspx (emphasis added). MMTE, even with a merging entity or JV partner, therefore faces formidable industry-entry costs similar to, say, a start-up company just trying to get a foot in the door of the oil exploration/extraction industry.

Moreover, even small mining operations require relatively expensive and environmentally controversial lithium mining equipment and facilities (e.g., drilling rigs, commercial grade brine water pumps, miles of piping, giant evaporators, thousands of acres of solar evaporation basins, raw lithium salt harvest machinery, concentrator facilities, condensers, complex canal systems, grinding mills, ball mills, processing facilities, potash recovery facilities, refineries, lithium chemical refinement plants, lithium mineral refinement plants, storage tanks, a means of ore/brine water and product transportation, tanker trucks, buses, waste processing facilities, etc.). See, e.g., id.; see also "The Trouble with Lithium II: Under the Microscope," supra, pp. 1-5, 17, 33, 46 ; TRU GROUP, "Tru Lithium," @ http://trugroup.com/Lithium-Battery.html . Such systems, mills, equipment, and processing facilities allow the production of lithium from minerals in brine water lithium "ore" (e.g., underground brine pools, mineral springs) or regolith ore (e.g., crusted salt layers with tiny lithium deposits). Without such equipment, facilities, and the professionals required to operate them – profiting off lithium land concessions proves extraordinarily rare.

Indeed, even if the owner of the concessions (e.g., MMTE) manages to bring in another company to do all the “dirty work” of mining, processing, refining, and transporting the market-grade lithium, the company completing the “dirty work” implicitly earns almost all the profit! The “dirty work,” which MMTE is in no place to perform, is what brings the vast majority of the value to the almost worthless trace amounts of lithium floating around in the extraordinarily isolated and evasive groundwater of the Chilean high deserts to highly profitable commercial/technical grade, purified, refined, marketable, and profitable lithium metals. The “owner” of the concessions only owns the nominal, “static” value of the trace lithium amounts 5,500 miles away from Silicon Valley in the middle of some damn desert in the middle of nowhere. The owners, human resource coordinators, and operators of all that expensive and environmentally controversial deep desert lithium mining equipment and facilities incur massive risks and expenses to make ready the trace lithium particles under the high desert floor for purchase as commercial/technical grade by the end-users. THOSE are the entities that make the money, not the “absentee” landlord such as MMTE seems it will become, as it has done virtually nothing to engage in the above eight phases required of a successful mining company. MMTE will likely never mine one ounce of lithium; some other company will do it and make the vast lion’s share of the profits. See, e.g., id.; see also J.A. Ober, United States Geological Survey,"Lithium," 77–78 (Aug. 2007).

THE VALUE IN THE GROUND???

The Chilean high deserts are vast, remote, and inhospitable geographic regions dotted with sporadic salt beds or “salars.” Under some of these salars lie pools of brine water that contain anywhere from faint to fairly rich concentrations of lithium ore. From these salars and brine waters, experienced and well-funded mining exploration and development companies painstakingly prospect for the most lithium-ore-rich lodes to extract, transport, process, refine, and sell for high dollar to end users such as lithium-ion battery manufacturers.

Some say that MMTE's value is based in the lithium in the ground… that all of the other, above aspects of exploration, mining, evaporation, harvesting, processing, refining, transporting, selling, etc., mean nothing. A more ludicrous statement one would find hard to make. As discussed, the owner of lithium mining concessions own only the scant value of the trace lithium amounts floating in the groundwater in one of the world’s most barren and isolated regions. The value is just not there, especially where other regions prove far more lithium-rich than the concessions obtained by MMTE.

First, unless MMTE can find an entity crazy enough to merge or create a joint venture with the devalued, diluted, forlorn, newcomer MMTE to mine & refine lithium (eventually) the relatively tiny land acquisitions/mining concessions MMTE required some sort of an ownership interest in – or some such other miracle happens – I believe MMTE will have mislead investors, financiers, financial institutions, and perhaps governments. MMTE will thus, IMHO, find itself in a world of hurt sooner than later.

Second, The world's most lithium-rich geographical salars do NOT include MMTE's purported "concessions" to relatively small salar portions deep within Chile's most inhosptiable region (e.g., Salar de Maricunga, Salar del Laco, Salar de Pujsa). Indeed, the world's primary/vastly superior lithium-rich and lithium-producing salars - among which one will fine ZERO (0) MMTE salar concessions - include: (1) Salar de Hombre Muerto; (2) Salar de Rincon; (3) Cauchari, (4) Olaroz, (5) Salar de Uyuni, (6) Salar de Atecama, (7) Taijanier Lake, (8) Zhabuye, and (9) Silver Peak. MMTE's concessions are not among the world's approximate top ten lithium salar land masses, and as far as lithium-producing salars go, there really are not very many of them in toto anywhere on the planent. See, e.g., MMTE Website @ http://www.mammoth-energy.com/projects.php ; Signum Box, "Salar de Maricunga: Project Review," p.5, tab. 3 (June 2011) @ http://www.li3energy.com/projects/signumBOX/IVG-LIEGsignumBOX2011.pdf ; Lithium Investing News, "World Class Deposit" @ http://lithiuminvestingnews.com/investing-in-lithium/lithium-world-class-deposit ; R.K. Evans, An Abundance of Lithium II @ http://www.worldlithium.com/AN_ABUNDANCE_OF_LITHIUM_-_Part_2.html ; New World Resource Corp., "Projects About Lithium," @ http://www.newworldresource.com/s/AboutLithium.asp .

Third, based on the press releases and, inter alia, the above data (including all cited information/links), MMTE appears far from establishing even the most basic resources required to mobilize and initiate a successful precious metal mining and refining operation. Moreover, without mammoth dilution and/or a reverse split, MMTE will almost certainly find itself unable to finance the colossal industry entry costs inherent to precious metal mining - small Brine Mining operations included. Further, where MMTE is nothing short of a financial train wreck and where MMTE's purported salar land ownership interests are NOT found among the very few, lithium-rich salars on the planet, one would find it rather unlikely that any truly viable or reputable mining company might want to enter a joint venture or merge with the cash-strapped, struggling, heavily O/S diluted, forlorn penny stock, MMTE.

Simply put, MMTE bought comparatively crappy salar concessions because that is all it could afford, even after selling so many shares to the 'investors' that are the so-called MMTE common shareholders, i.e., us! Value in the ground? Not so much!

SUMMARY

Without question, the above evidence and concordantly cited authority sources evidence the cold, hard fact that MMTE is a long way from selling its concessions, entering into a JV, producing any profit, or even a longer way from delivering any significant amount of lithium for purchase by end users. Either in finding a merger or JV candidate or going it alone, MMTE faces a competitive, potentially expensive, and uphill battle that simple common sense increasingly indicates MMTE proves unlikely to win.

Private forums may not delete posts based on cleanly expressed opinions; deleted posts must also firmly oppose a forum's innate purpose. See Ark. Educ.Comm'n v. Forbes, 523 U.S. 666, 682 (U.S. 1998).

Join the InvestorsHub Community

Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.