Thursday, January 19, 2023 4:41:18 PM

https://www.tmcnet.com/usubmit/2023/01/19/9746070.htm

Elcyon will be an essential component of the supply chain to continue developing our nation's offshore wind power infrastructure. The recent passage of the Inflation Reduction Act, which included $300 billion for clean energy development and climate programs, supports the Biden Administration's goal to build 30 gigawatts of offshore wind power by 2030. This could result in approximately 7.5 million tons of additional steel demand and create enough clean energy to power 10 million homes.

Niobium in high strength low alloy (HSLA) steel

HSLA steel has a ferritic-pearlitic microstructure providing medium-high strength and offering moderate press formability. It has good fatigue resistance and excellent weldability.

Strength is generated by grain refinement for the lower grades and a combination of grain refinement and precipitation hardening for the higher grades.

Niobium provides both strengthening mechanisms to the highest extent amongst all microalloying elements.

In hot-rolled HSLA steel both, grain refinement and precipitation hardening, can enable around 200 MPa yield strength increase each. Thus, the sole addition of 0.05-0.06% Nb to low-carbon manganese steel basically allows producing hot strip with 600 MPa yield strength.

Cold-rolled HSLA steel practically applies the same alloy concepts as hot-rolled grades.

However, due to annealing after cold rolling the grain size increases somewhat and over-ageing of particles reduces precipitation hardening. Thus, cold-rolled HSLA steel is always softer than the hot-rolled sibling.

Steelmakers often apply a Nb-only microalloying alloy strategy for producing these steels.

Cold-rolled HSLA steel is recently being supplied with up to 500 MPa yield strength.

Niobium's benefits in automotive flat steel

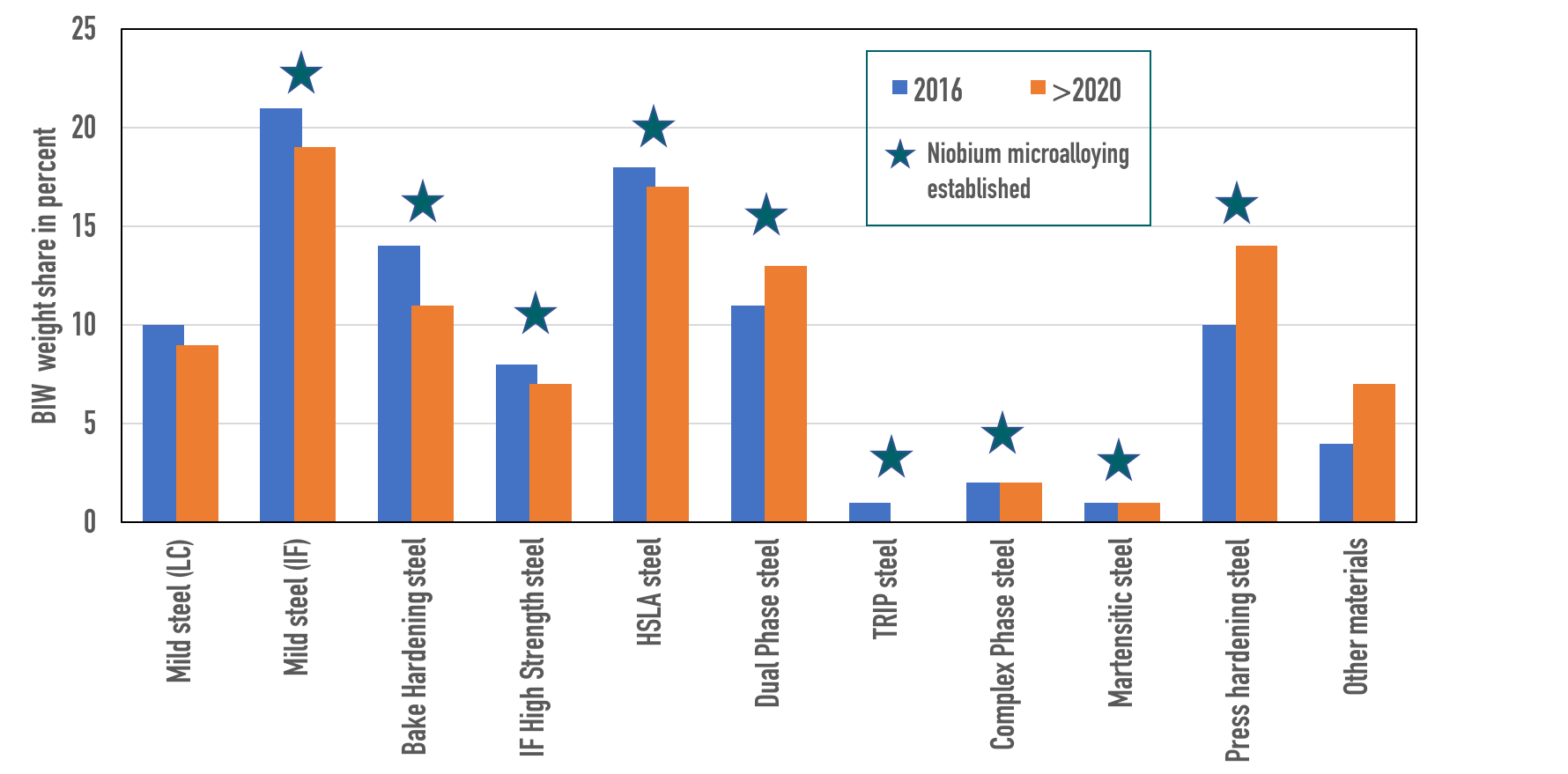

Modern automotive sheet steel covers a wide range of properties from very soft grades with highest formability to extremely strong grades being very difficult to form. In the same respect the carbon content ranges from nearly zero in interstitial-free steel up to 0.35% in the strongest press hardening steel.

In the widely used HSLA steel grades the addition of carbon is mediated against microstructural optimization with the aim of obtaining high strength steel having acceptable formability and weldability.

Niobium microalloying has been established in these steels as the most efficient element for obtaining grain refinement and precipitation strengthening.

Furthermore, niobium acts as a carbon stabilizer providing steel with an interstitial-free matrix.

These well-known direct metallurgical benefits of niobium are complemented by several less-known indirect effects bringing substantial benefits for either processing the steel in the mill or improving particular properties of the steel. Examples of such indirect benefits are:

Crystallographic texture control, Phase transformation kinetics, Stabilization of mechanical properties, Improved bendability and flange ability, &

Hydrogen trapping.

PRODUCING VALUE-ADDED NIOBIUM STEELS FOR AUTOMOTIVE APPLICATIONS USING THE CSP PROCESS

AT NUCOR STEEL BERKELEY

https://assets.niobium.tech/-/media/niobiumtech/attachments-biblioteca-tecnica/nt_producing-value-added-niobium-steels-for-automotive-applications-using-the-csp-process-at-nucor.pdf

(Maybe They could use some U.S. produced Niobium? or Not... ) Either Way this construction dude is very happy to see U.S. STEEL being used to build things here in the U.S.!

Chico

Recent NB News

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 02/16/2024 04:28:49 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 02/15/2024 10:02:51 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 02/15/2024 10:01:47 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 02/15/2024 10:01:29 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 02/15/2024 10:00:51 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 02/15/2024 10:00:33 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 12/22/2023 09:00:27 PM

- Form D - Notice of Exempt Offering of Securities • Edgar (US Regulatory) • 12/21/2023 09:45:51 PM

- Form 8-K - Current report • Edgar (US Regulatory) • 12/20/2023 09:55:17 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 11/17/2023 09:30:58 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 11/17/2023 09:30:47 PM

- Form 4 - Statement of changes in beneficial ownership of securities • Edgar (US Regulatory) • 11/17/2023 09:30:35 PM

- Form 8-K - Current report • Edgar (US Regulatory) • 09/13/2023 12:30:19 PM

- Form 8-K - Current report • Edgar (US Regulatory) • 09/12/2023 09:01:20 PM

- Form 8-K - Current report • Edgar (US Regulatory) • 09/07/2023 12:30:18 PM

- Form 8-K - Current report • Edgar (US Regulatory) • 09/06/2023 12:30:17 PM

- Form 8-K - Current report • Edgar (US Regulatory) • 09/01/2023 08:30:22 PM

FEATURED Music Licensing, Inc. (OTC: SONG) Subsidiary Pro Music Rights Secures Final Judgment of $114,081.30 USD, Demonstrating Strength of Licensing Agreements • May 17, 2024 11:00 AM

Greenlite Ventures Inks Deal to Acquire No Limit Technology • GRNL • May 17, 2024 3:00 PM

VPR Brands (VPRB) Reports First Quarter 2024 Financial Results • VPRB • May 17, 2024 8:04 AM

ILUS Provides a First Quarter Filing Update • ILUS • May 16, 2024 11:26 AM

Cannabix Technologies and Omega Laboratories Inc. enter Strategic Partnership to Commercialize Marijuana Breathalyzer Technology • BLO • May 16, 2024 8:13 AM

Avant Technologies to Revolutionize Data Center Management with Proprietary AI Software Platform • AVAI • May 16, 2024 8:00 AM