| Followers | 2 |

| Posts | 1540 |

| Boards Moderated | 0 |

| Alias Born | 05/06/2017 |

Sunday, January 17, 2021 9:45:59 AM

5

source

https://wfsinc.com/brands

Prins

CNG, LNG, and LPG systems for light-, medium-, and heavy-duty applications

https://www.prinsautogas.com/de

High quality alternative fuel systems and components for cars , buses, trucks, industrial and water vehicles.

WHO WE ARE?

Prins Autogassystemen BV was founded in 1986 as a Dutch developer and manufacturer of high quality alternative fuel systems for LPG, CNG and LNG. Prins is part of Westport Fuel Systems.

Our motto:

Quality, Innovation and Customer Care, it's in our nature! (Quality, innovation and customer care are in our nature!)

Expert for over 30 years

Prins Autogassystemen BV, part of Westport Fuel Systems, has been a leader in the development of alternative fuel systems for LPG, CNG and LNG for more than 30 years. We offer our customers cost-effective and innovative solutions for a wide range of engine types.

Thanks to our extensive product range for modern direct injection engines (DI), we have a unique position in the market.

Why do customers choose Prins?

We have been leaders in fuel system development for more than 30 years. Whether cars, buses, trucks, industrial or water vehicles, we offer a solution for almost all engine types and technologies. We also distinguish ourselves through our solutions for state-of-the-art engines with direct injection (DI).

By working with our committed global partners, we ensure that our systems are in line with the latest developments in the industry.

Award-winning innovations

Very extensive range for DI engines

Dedicated and highly qualified employees

Focus on quality and sustainability

One stop shop

Worldwide service network

Distribution partner:

https://www.prinsautogas.com/de/vertriebspartner

We are ready for the future!

Did you know that ... hybrid cars can also be converted to LPG and CNG ?!

This means that you as the driver can switch between electric mode, driving on petrol and driving on LPG in order to achieve a long range and to minimize harmful exhaust emissions.

Organic LPG is on the rise!

The chances are good that the already widely recognized fuel LPG will be made even more popular in the course of reducing Co2 emissions. Drivers with an LPG system will be able to refuel with bio-LPG in the next year.

Watch our company film

https://www.youtube.com/watch?v=mjzE1kCvLBk

Driving with gas

We develop and deliver systems for this cleaner, more affordable alternative fuel. Our systems are suitable for both older and new engines with direct injection and hybrid vehicles. Driving with our systems, with gas as fuel, offers many advantages such as fuel cost savings and more environmentally friendly driving. Read experience reports on driving with gas here.

LPG

What is LPG and what is LPG?

LPG (Liquefied Petroleum Gas) is also known as autogas in the automotive industry and, like gasoline and diesel, consists of hydrocarbon compounds. The main components of liquefied petroleum gas are propane and butane. Large amounts of petroleum gases are released both in the extraction of oil and natural gas and in the refining of crude oil. The compression of these petroleum gases turns the gas into liquid and creates LPG.

Compared to gasoline and diesel, LPG is a cleaner fuel. The use of liquefied petroleum gas as fuel thus contributes to better air quality.

Driving with LPG (Autogas)

LPG is more environmentally friendly and cheaper!

For a liter of LPG you pay almost one euro less than for a liter of petrol. In addition, it is a clean fuel. When your car runs on LPG, it emits up to 21% less CO2 and up to 95% less particulate matter than when driving on gasoline. With regard to NOx (nitrogen oxides), LPG produces significantly lower emissions than driving with petrol or diesel. Bio-LPG - an even more environmentally friendly variant - will also be available shortly.

The benefits of LPG

Savings in fuel costs

Greener driving

Nationwide petrol station network

Convenient refueling

No loss of performance

Additional range

Suitable for millions of gasoline vehicles already on the market!

The story of LPG - See the video

https://www.youtube.com/watch?v=oRbrfzPluTE

"Greater attention should be paid to the role that LPG can play in the energy transition."

Various LPG systems

VSI system

VSI is the abbreviation for “ Vapor Sequential Injection ” (vapor sequential injection). The VSI system is the most advanced steam injection system on the market. It was developed by Prins and fully adapted to the most modern engines. All components of the VSI system comply with the strictest legal regulations and certifications .

The VSI system is based on the principle of injecting autogas ( LPG ) or natural gas ( CNG ) in vapor form and sequentially into an engine. We also offer solutions for vehicles with direct injection .

High quality components

Special diagnostic software

Optimal performance

Reduced emissions

You will not notice any difference to driving on gasoline!

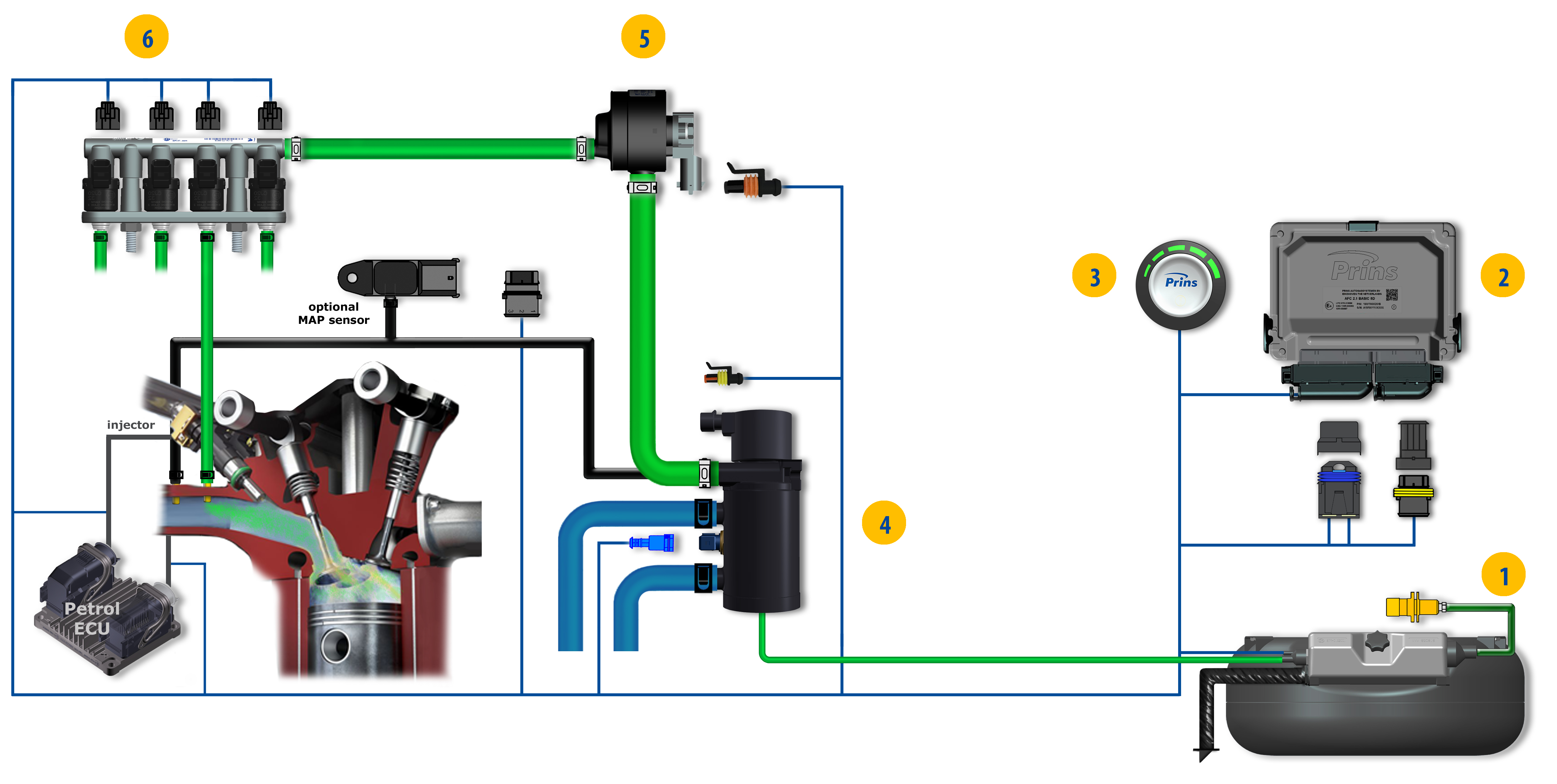

Main components that are added to your vehicle when installing an LPG system*.

* With a few modifications, the Prins VSI LPG system is also suitable for CNG vehicles

Below is a list of the different components that make up our VSI system. The main components are of OEM quality (Original Equipment Manufacturer = original equipment manufacturer quality) and have been specially developed for LPG and CNG systems. They comply with the strictest legal regulations and certifications.

1. LPG tank

2. ECU (Electronic Control Unit)

3. Switch

4. Evaporator (eVP-500)

5. Filter

6. Injectors

VSI-DI system

VSI is the abbreviation for "Vapor Sequential Injection". The advanced VSI-DI system is a further development of the VSI system. It was specially developed for vehicles with the so-called Direct Injection Fuel System (engines for direct injection).

Compared to other competitors in the market, Prins offers reliable fuel systems for a wide variety of vehicles. The VSI-2.0 DI system consumes very little gasoline (<5%) and is suitable for the latest vehicle types as well as for vehicles that have been on the market for several years.

The VSI-DI system is based on the principle of injecting autogas ( LPG ) or natural gas ( CNG ) in vapor form and sequentially into a DI engine (engine with direct injection)

Most advanced software

Especially for direct injection engines

High quality components

Maximum performance, minimum emissions

Very low fuel consumption (<5%)

You will not notice any difference to driving on gasoline!

What changes in the car when a VSI 2.0 LPG system is installed?

When you drive on LPG (Autogas), you benefit from a number of advantages, such as saving fuel costs and reducing emissions of CO2, fine dust and NOx (nitrogen oxides).

You can have your gasoline-powered car converted to LPG by an authorized Prins dealer. The video shows in just a few steps which adjustments are made to your car.

Various LPG components are installed inside the vehicle and under the bonnet

The LPG tank is (usually) installed at the location of the spare wheel so that no trunk space is lost

The LPG tank filler neck is usually located behind the flap next to the petrol tank filler neck

The fuel selector shows you how full your LPG tank is. If necessary, you can switch manually between LPG and petrol operation.

See the video - INSTALL A PRINS VSI 2.0 LPG SYSTEM:

https://www.youtube.com/watch?v=Vs5W3sR2IVA

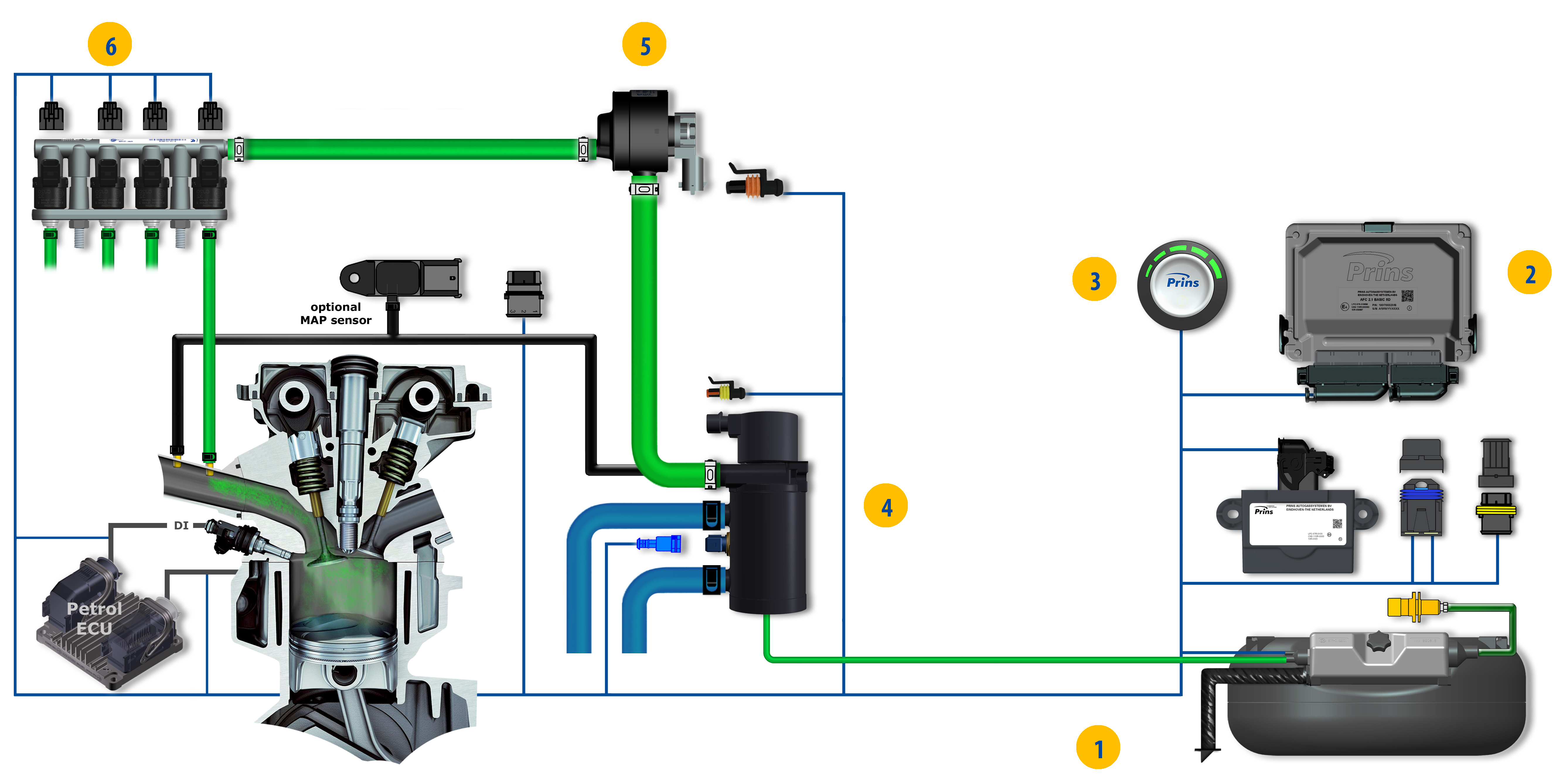

Main components that are added to your vehicle when installing an LPG system.

Below is a list of the various components that make up our VSI-DI system. the main components are of OEM quality (Original Equipment Manufacturer = original equipment manufacturer quality) and have been specially developed for LPG and CNG systems. They comply with the strictest legal regulations and certifications.

1. LPG tank

2. ECU (Electronic Control Unit)

3. Switch

4. Evaporator (eVP-500)

5. Filter

6. Injectors

Direct LiquiMax system

DLM stands for "Direct LiquiMax". This system is based on the liquid injection of LPG into an engine using direct injection (DI) technology. In addition to the VSI-DI system, the DLM system is also suitable for vehicles with direct injection.

The Prins Direct LiquiMax system consists of a number of high-quality components that are installed in parallel to the standard fuel system. The DLM system uses a number of components and electronics that are already present in the vehicle. This ensures optimal integration.

High quality components

For vehicles with direct injection (DI) engines

For mono and bi-fuel applications

Extremely low fuel consumption

Significantly reduced emissions

Award winning product

You will not notice any difference to driving on gasoline!

Main components that are added to your vehicle when installing an LPG system.

The following is a list of the different components that make up our DLM system. The main components are of OEM quality (Original Equipment Manufacturer = original equipment manufacturer quality) and have been specially developed for LPG and CNG systems.

They comply with the strictest legal regulations and certifications.

1. LPG tank with fuel module

2. ECU (Electronic Control Unit)

3. Switch

4. Fuel management unit Fuel management unit (FMU)

5. High pressure pump (fuel pump)

6. Boost pump (pressure increasing pump)

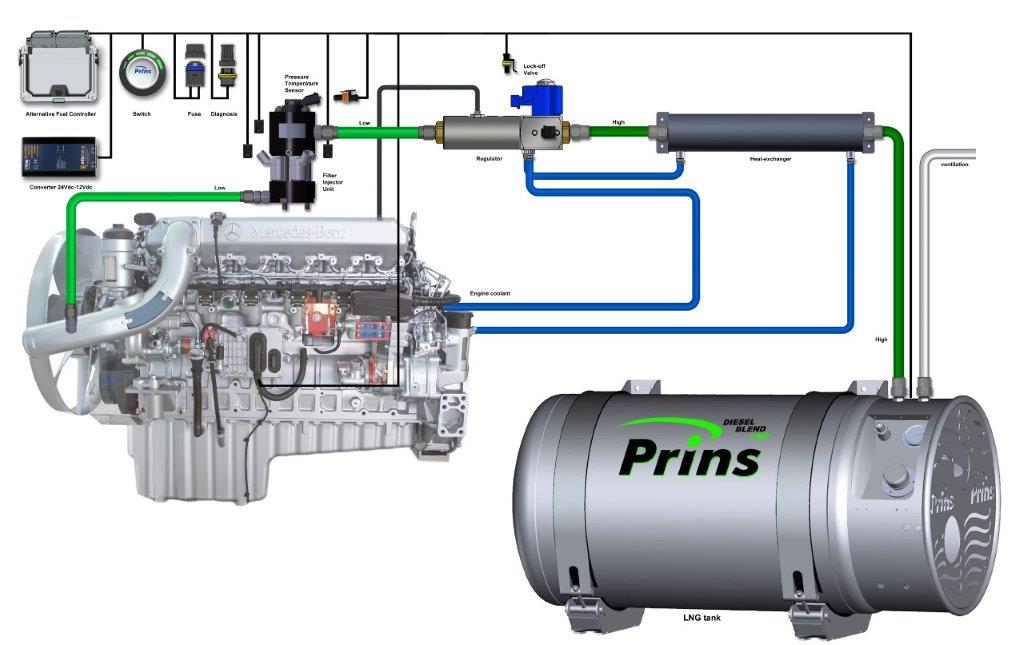

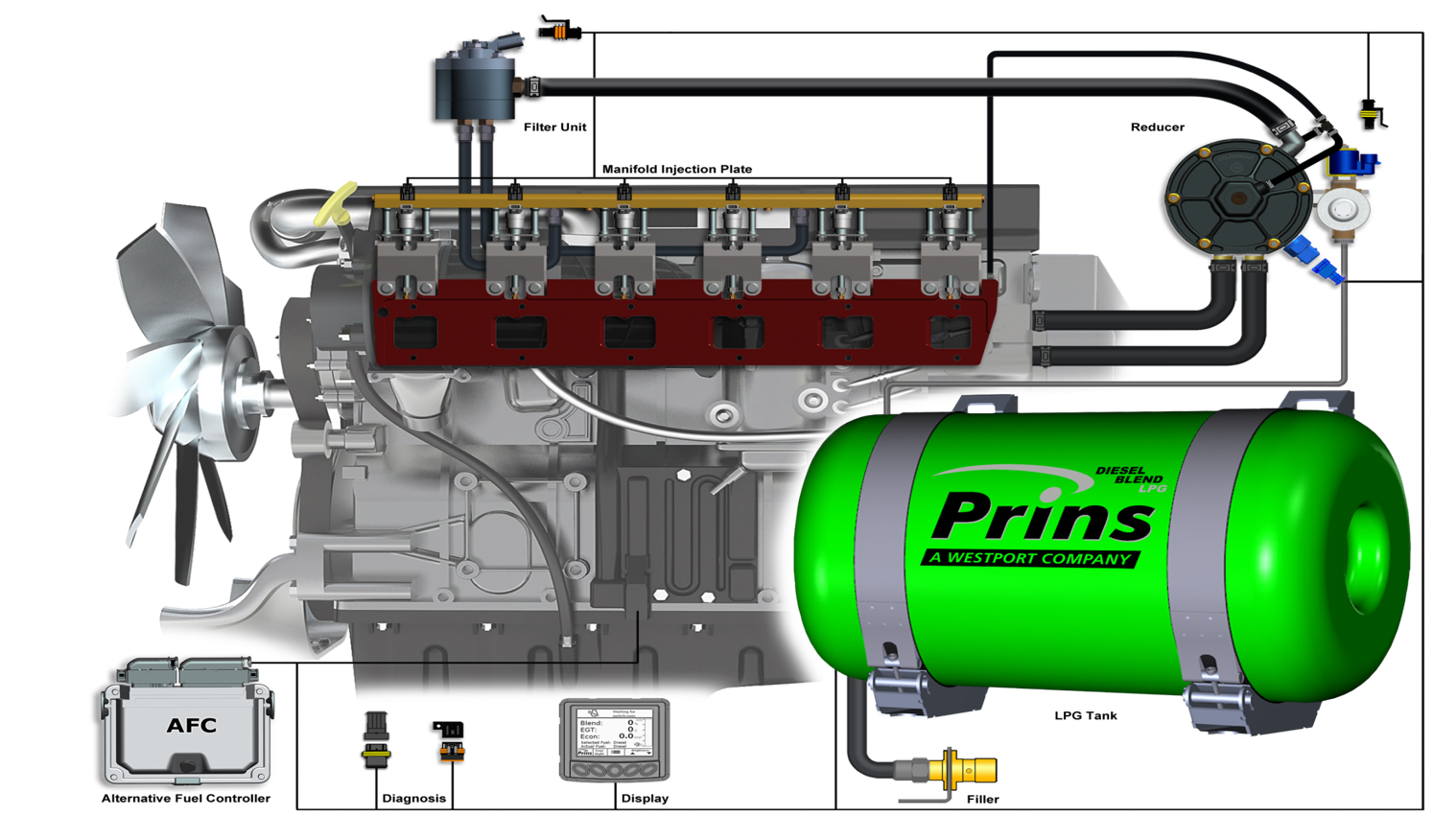

Diesel blend dual fuel system

The diesel blend dual fuel system from Prins is an extremely innovative fuel system. In the case of diesel engines, this system enables a considerable proportion of diesel to be replaced by cleaner and cheaper (bio) LPG , CNG or LNG .

The advanced electronics and software of the injection system combine the two fuels in such a way that an optimal mixture of diesel and alternative fuel (LNG / LPG / CNG) is created. The Prins-Dieselblend-AFC (Alternative Fuel Computer = computer for alternative fuel) calculates in real time the amount of diesel fuel that can be replaced. The AFC also calculates the amount of gas to be injected, ensuring the same power and torque as the original diesel fuel. This reduces consumption and operating costs without affecting the service life and performance of the engine.

High quality components

Special diagnostic software

Optimal performance

Reduced emissions

Depending on the vehicle type and your needs, there are several options for accommodating gas tanks.

Main components that your vehicle needs when installing an LPG / LNG / CNG diesel blend.

The following is a list of the different components that make up our LPG / LNG / CNG diesel blend system. The main components are of OEM quality (original equipment manufacturer - quality) and have been specially developed for LPG, CNG and LNG systems. They comply with the strictest legal regulations and certifications.

1. LNG tank

2. Prins AFC computer (Alternative Fuel Computer = computer for alternative fuel)

3. LNG pressure regulator

4. Heat exchanger

5. Filter injection unit

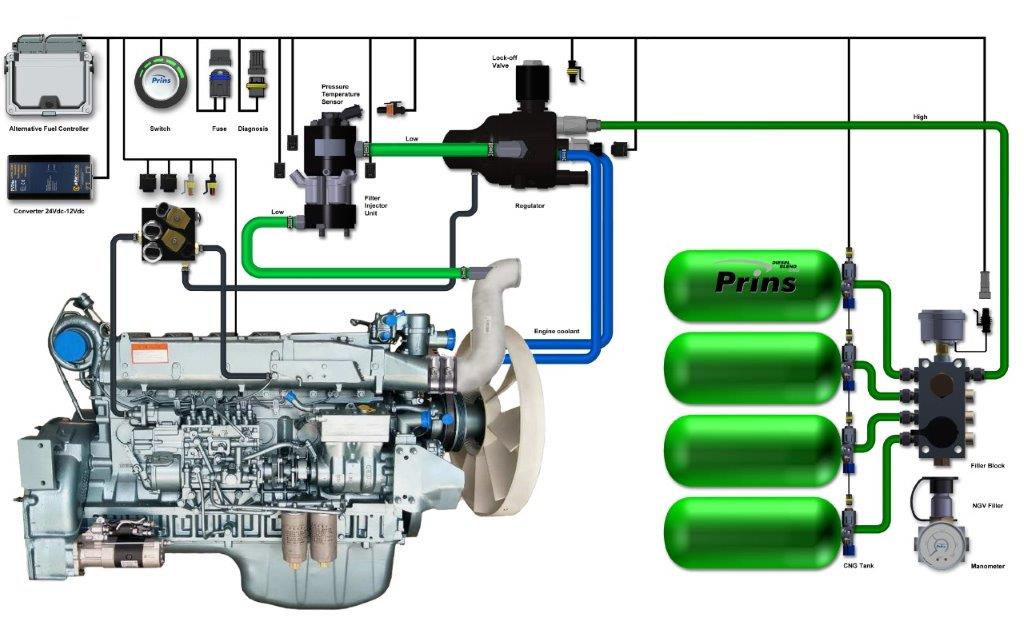

CNG diesel blend dual fuel system

1. CNG tank

2. Prins AFC computer (Alternative Fuel Computer = computer for alternative fuel)

3. CNG pressure regulator

4. Filter injection unit

If required, the system can also be equipped with a high pressure gas filter.

LPG diesel blend dual fuel system

1. LPG tank

2. Prins AFC computer (Alternative Fuel Computer)

3. LPG evaporator

4. Filter unit

5. Distributor injection plate

If required, the system can also be equipped with a high pressure gas filter.

ValveCare (-DI)

Why should you use ValveCare (-DI)?

The valves and valve seats of some engines are more prone to wear when operated with LPG or CNG . With gasoline engines, this problem does not occur because certain additives are added to the gasoline to lubricate the valves and valve seats. These additives are not contained in LPG and CNG fuels. With the Valve Care dosing system, these additives can be added together with the LPG or CNG in precisely dosed quantities, which prevents excessive wear on the valves and valve seats.

ValveCare

ValveCare is a unique dosing system for additives that counteracts the wear and tear of valves and valve seats. It has been specially developed and extensively tested. ValveCare is suitable for almost all Prins systems.

ValveCare guide:

https://www.prinsautogas.com/sites/default/files/media/members/technical-system-info/valvecare/Gebruikershandleiding_ValveCare.pdf

ValveCare-DI

General information:

The ValveCare DI system is a fully electronic, sequentially controlled additive dosing system, which is suitable for engines with direct injection (DI). In combination with the highly effective Prins additive (ValveCare-DI), the system contributes to a cleaner combustion chamber and an improved durability of valves and valve seats against excessive wear.

Diagnosis:

The consumption of the additive ValveCare-DI is 1 liter of additive per 1,000 liters of liquid gas. The additive container can be refilled at any time. When the additive tank is empty, the Prins switch will display a blue exclamation mark (flashing) and the engine can run for an additional 4 hours on LPG. After this time, the engine will only run on petrol and the exclamation mark will remain visible. By filling the additive tank, driving with LPG is possible again.

What you should know:

• One bottle of ValveCare-DI (1L) is sufficient for approx. 1,000 liters of liquid gas.

• Do not use or mix any other additive with the original Blue Prins

• ValveCare-DI additive. Using any other additive could damage the system and void the warranty immediately.

• Please contact your official Prins installer for more information.

List of ValveCare-DI:

InjectorCare

InjectorCare is a cleaning fluid that we have developed for cleaning LPG, CNG and DI injectors. By using InjectorCare you can keep the Prins system and the original fuel system in optimal condition.

With the use of InjectorCare, you avoid loss of engine performance, increased fuel consumption, increased exhaust emissions and starting problems.

When do you use InjectorCare?

Preventive cleaning with InjectorCare can be combined with normal maintenance of the Prins LPG and CNG systems. Prins recommends cleaning the gas injectors preventively at every service (<75,000 km) in accordance with the cleaning procedure recommended by the manufacturer.

InjectorCare has been extensively tested and found to be the only cleaning fluid for the injectors supplied by Prins to be safe. The use of other cleaning fluids can damage the seals in the gas injector of the Prins gas systems.

How is Prins-InjectorCare used?

https://www.prinsautogas.com/sites/default/files/media/particulieren/systemen/Text%20Instruction%20Manual%20Prins%20InjectorCare.pdf

CNG

CNG stands for "Compressed Natural Gas". It is basically compressed natural gas.

Driving with CNG or green gas

CNG is one of the cleanest fuels. It emits fewer harmful gases and substances than gasoline. The CO2 emissions are reduced by up to 20%. Compared to diesel, the emission reduction can even be up to 75%. In addition, a CNG vehicle emits up to 30% less NOx (nitrogen oxide) than a vehicle powered by diesel.

Green gas is the sustainable variant of natural gas. It is generated by upgrading biogas to natural gas quality. Green gas is produced through the fermentation of green and cut waste, sewage sludge and liquid manure.

Anoher advantage of CNG is the price difference compared to gasoline and diesel. CNG is much cheaper. So you save on fuel costs. These savings vary depending on the vehicle type and driving style.

Our CNG systems

- VSI System

- VSI-DI system

- Diesel blend dual fuel system

LNG

LNG stands for "Liquefied Natural Gas", that is, liquefied natural gas. LNG is used as a fuel for road traffic as well as for industrial and water vehicles.

Driving with LNG

LNG is the ideal fuel for heavy haulage and transportation over. The global use of LNG is growing rapidly and the role of LNG as an energy source is becoming increasingly important. Compared to diesel and petrol, LNG offers more environmentally friendly and cheaper solutions.

Prins developed the Dieselblend -2.0 LNG System (Dual Fuel) to operate vehicles reliably and efficiently with LNG. The Dieselbled system is also available in a CNG and an LPG version.

Would you like to know more about us?

Corporate Responsibility

Zero emission

" We are constantly developing our high-quality alternative fuel systems, with the ultimate goal of developing an emission-free system."

How do we do that?

The increasingly strict emission standards for vehicles are aimed at accelerating the development and introduction of new, more environmentally friendly vehicle technologies. Our technological developments lead to a drastic reduction of the pollutants in the exhaust gases (CO2, soot particles, NOx (nitrogen oxides)). As a result, vehicles now emit 20 times less harmful emissions than vehicles produced in 1970.

To achieve our ultimate goal, we will focus on three main points:

quality

innovation

Customer care

Engineering at an international level

Innovation is an important cornerstone for Prins. We are leaders in the development and delivery of innovative alternative fuel systems for the operation of vehicles with LPG, CNG or LNG. We are currently active in more than 50 countries. We have developed high quality technologies such as VSI , DLM and diesel blend for the most common types of engines, including engines with direct injection.

All components, software and systems are developed by our research and development team and tested together with our application technology department according to industry standards.

Patents

We have received a number of patents on our innovations. Together with our partners and suppliers, we are driving this development forward.

Reliability and quality

In addition to functionality, we focus on reliability and quality. All of our components comply with and meet EU regulations and standards. R67 / R10 / R110 / R110 / R115 / CSA / EPA / ISO15500 and have been fully tested.

Awards

Prins' innovations are widely recognized. We have received many renowned (industry) awards such as the INPRO Award, the “Automechanika Green Directory and Innovation Award”, the “Gouden Duurzame Ondernemer Award” and various other awards for our products, for sustainability and the way we maintain our partnerships Awards from our partners.

"Prins is primarily characterized by quality, innovation and customer service."

BART VAN AERLE - CEO OF PRINS AUTOGASSYSTEMEN BV

Certifications and approvals

Quality makes Prins Autogassystemen BV a crucial part of every business process. It is the top priority both in our production process and in the manufacture of our systems.

Our entire quality system and our operating processes are tested according to the NEN-EN-ISO 9001: 2015 standards and certified by TÜV Nederland QA BV.

We meet all OEM-related processes in accordance with the relevant automotive standards IATF16949: 2016. This ensures that Prins can achieve and deliver the highest level of OEM quality.

In addition, all system components and assemblies are certified according to the quality standards R67-01, R10, R110 and R115. CSA supplies certified products and systems for the Canadian and North American markets. Prins supplies ISO15500-approved components and systems for the Asian market and the Middle East.

The various certificates and approvals are regularly checked by automotive-related testing institutes such as RDW, TÜV, KBA and Kiwa.

news:

https://www.prinsautogas.com/de/neuigkeiten

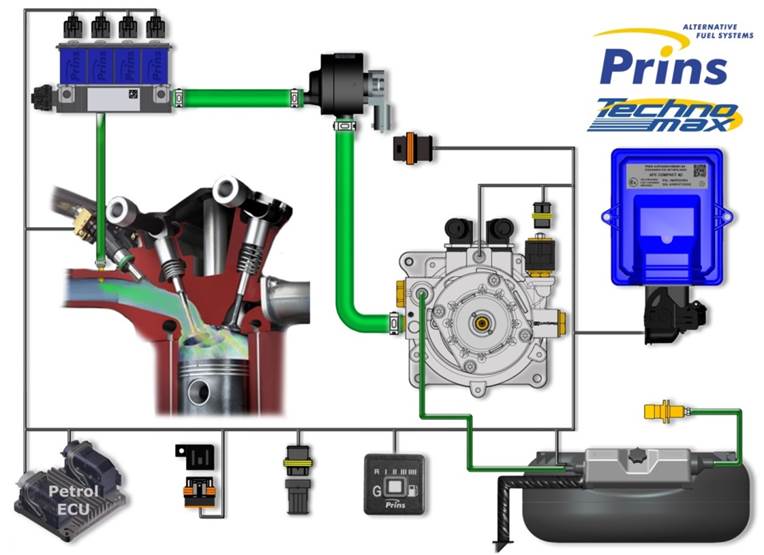

TechnoMax

The technology of the TechnoMax system is based on VSI technology . The main differences are the more compact evaporator and the simpler injectors, which make this system ideal for compact 3 and 4 cylinder engines up to 140 hp. The system also has a square dashboard switch with green LEDs.

The TechnoMax system was introduced as an alternative to the VSI system for certain markets.

CONTACT INFORMATION

Prins Autogassystemen BV

Jan Hilgersweg 22

5657 ES Eindhoven

Netherlands

T +31 (0) 40 254 77 00

sales@prinsautogas.com

Directions

https://www.facebook.com/prinsautogassystemen

https://twitter.com/Prins_Autogas

https://www.youtube.com/user/Prinsautogassystemen

© 2021 - PRINS AUTOGASSYSTEMEN BV

Recent WPRT News

- Form 6-K - Report of foreign issuer [Rules 13a-16 and 15d-16] • Edgar (US Regulatory) • 09/13/2024 09:15:04 PM

- Form SUPPL - Voluntary Supplemental Material by Foreign Issuers [Section 11(a)] • Edgar (US Regulatory) • 09/13/2024 09:14:05 PM

- Westport Announces At-the-Market Equity Offering Program • GlobeNewswire Inc. • 09/13/2024 09:00:00 PM

- Form 6-K - Report of foreign issuer [Rules 13a-16 and 15d-16] • Edgar (US Regulatory) • 08/13/2024 09:15:04 PM

- Form 6-K - Report of foreign issuer [Rules 13a-16 and 15d-16] • Edgar (US Regulatory) • 08/13/2024 09:04:46 PM

- Westport Reports Second Quarter 2024 Financial Results and Revises Segment Reporting • GlobeNewswire Inc. • 08/13/2024 09:00:00 PM

- Form 6-K - Report of foreign issuer [Rules 13a-16 and 15d-16] • Edgar (US Regulatory) • 07/26/2024 02:17:20 PM

- Westport to Issue Q2 2024 Financial Results on August 13, 2024 • GlobeNewswire Inc. • 07/25/2024 11:15:00 PM

- Volvo Group and Westport Celebrate Transformative Partnership • GlobeNewswire Inc. • 07/05/2024 10:30:00 AM

- Westport Fuel Systems Publishes 2023 ESG Report • PR Newswire (Canada) • 06/25/2024 09:00:00 PM

- Westport Fuel Systems Publishes 2023 ESG Report • PR Newswire (US) • 06/25/2024 09:00:00 PM

- Westport Fuel Systems Publishes 2023 ESG Report • PR Newswire (US) • 06/25/2024 09:00:00 PM

- Westport Publishes Annual General Meeting Results • PR Newswire (Canada) • 06/13/2024 10:00:00 PM

- Westport Publishes Annual General Meeting Results • PR Newswire (US) • 06/13/2024 10:00:00 PM

- Westport and Volvo Group Announce Closing of the Joint Venture • PR Newswire (US) • 06/03/2024 09:00:00 PM

- Westport and Volvo Group Announce Closing of the Joint Venture • PR Newswire (Canada) • 06/03/2024 09:00:00 PM

- Westport and Volvo Group Announce Closing of the Joint Venture • PR Newswire (US) • 06/03/2024 09:00:00 PM

- Form 6-K - Report of foreign issuer [Rules 13a-16 and 15d-16] • Edgar (US Regulatory) • 05/08/2024 09:07:15 PM

- Westport Fuel Systems Reports First Quarter 2024 Financial Results • PR Newswire (Canada) • 05/08/2024 09:00:00 PM

- Westport Fuel Systems Reports First Quarter 2024 Financial Results • PR Newswire (US) • 05/08/2024 09:00:00 PM

- Westport Fuel Systems Reports First Quarter 2024 Financial Results • PR Newswire (US) • 05/08/2024 09:00:00 PM

- Westport to Issue Q1 2024 Financial Results on May 8, 2024 • PR Newswire (US) • 04/23/2024 10:30:00 AM

- Westport to Issue Q1 2024 Financial Results on May 8, 2024 • PR Newswire (Canada) • 04/23/2024 10:30:00 AM

- Westport to Issue Q1 2024 Financial Results on May 8, 2024 • PR Newswire (US) • 04/23/2024 10:30:00 AM

- Westport's Alternative Fuel Technologies Can Play an Important Role in Meeting the Strengthened European Decarbonization Targets for Heavy-Duty Vehicles • PR Newswire (Canada) • 04/11/2024 10:30:00 AM

VHAI - Vocodia Partners with Leading Political Super PACs to Revolutionize Fundraising Efforts • VHAI • Sep 19, 2024 11:48 AM

Dear Cashmere Group Holding Co. AKA Swifty Global Signs Binding Letter of Intent to be Acquired by Signing Day Sports • DRCR • Sep 19, 2024 10:26 AM

HealthLynked Launches Virtual Urgent Care Through Partnership with Lyric Health. • HLYK • Sep 19, 2024 8:00 AM

Element79 Gold Corp. Appoints Kevin Arias as Advisor to the Board of Directors, Strengthening Strategic Leadership • ELMGF • Sep 18, 2024 10:29 AM

Mawson Finland Limited Further Expands the Known Mineralized Zones at Rajapalot: Palokas step-out drills 7 metres @ 9.1 g/t gold & 706 ppm cobalt • MFL • Sep 17, 2024 9:02 AM

PickleJar Announces Integration With OptCulture to Deliver Holistic Fan Experiences at Venue Point of Sale • PKLE • Sep 17, 2024 8:00 AM