Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.

How Some Companies Are Making Textiles More Sustainable

TIME LINK

Wthi all the good new , KT should feel comeratable to publish heavy vol. PR's from now on imo.

But i did read you post on the cost of PR's so i understand it if he will need to cut back on sum of PR and bomb us with few PR"S with a WoW effect .

kblb is going to succeed and beyond looking stupid with your posts, you are also going to be seen as foolish...a complete and utter fool...

As I always say, posting stupid quotes is like….just stupid…

Ben's reply to me ... "No, it was a systemic formatting issue ".

And I don't care what it was either but I do want the problem corrected. Once about 8 years ago a PR wasn't on Schwab and I complained to Schwab and about 45 minutes later it was there.

Honestly, I don't know what the issue was with that PR not hitting the news outlets. Ben said "the next release will be properly distributed. "

So, I am happy with that. We can speculate all we want.

My thoughts are since we missed getting the PR released to a good number of people... let's have a 2nd really important release this week and get it to everyone. There's stuff out there. I'm ready for price movement.

"But they are not going from 0 metric tons to 1000 metric tons per month overnight"

no shit sherlock...you think someone thought that?...lol

"I’d rather have KBLB go through a controlled growth that maintains quality than an uncontrolled growth that sacrifices quality. Wouldn’t you?"

id rather kblb make good silk like they can and hit tonnage asap...

I asked Ben if someone was trying to keep the PR quiet and he said... "No, it was a systemic formatting issue"

So there you have it.

Maybe it's as simple as IR needs to get his shit together.

jetow, you are correct. The PR needs to be released again. No BIG DEAL!

Unfortunately no.

Each moth does not produce eggs. Only those of the female persuasion. I’m pretty sure that females don’t count the number of eggs they produce and stop at 500. The number varies between 200 and 500.

But KBLB has discovered that you can’t just interbreed all of the silkworms you have grown. Some of them are better than others. Note the language from the most recent PR:

“Under the guidance of Dr. Nirmal Kumar and through a meticulous, statistically-based selective breeding protocol, the parental strains for the BAM-1 hybrid were further optimized during the production cycle.”

‘Selective breeding’ means not all of the silkworms were bred. We should all understand by now that maintaining and growing a breeding pool is far more complex than simply allowing all silkworms to make and keeping all of their progeny.

It’s hard to have patience when we have waited so long for success. Assuming the viability of the BAM-1 production model, KBLB can ramp up production over time. But they are not going from 0 metric tons to 1000 metric tons per month overnight, at least not if they want to maintain the quality of their silk.

I’d rather have KBLB go through a controlled growth that maintains quality than an uncontrolled growth that sacrifices quality. Wouldn’t you?

"Until you have made your first substantial production cycle, you are still learning how to crawl."

utterly ridiculous...

"Even if KBLB was capable of providing eggs for a thousand metric tons per year, don’t you think they would prefer a thousand tons of BAM-1/DS than eight hundred tons of mundane silk and 200 tons of BAM-1/DS."

kblb needs to take care of the partners they have in the countries they are in...kblb needs a whole lot of mulberry, land, buildings, workers, permits, water etc etc...and they dont own any of those things...its not just about what kblb wants, their needs, their money...

"Production costs will be about the same. Sales price for BAM-1/DS should be higher. Bigger markup = bigger profit."

sure...but in the real world, there is much more to consider and deal with than that...

"KBLB may have done some useful work in developing disease resistant silkworms. But that can be done by other competitors."

saying it, doesnt make it so...its not as easy as you are making it...

Trainer2: “Seems like there will be a time in the future where the rocket engine will be ignited.”

Emphasis on the word ‘future.’ Thompson has a long history of going off in too many different directions: immunity silkworms, nearly-pure spider silk, other variants on DS, all while neglecting the core problem: creating a robust silkworm platform to produce DS.

The last thing I want him to do is to attempt twelve more new directions at this time. KBLB may or may not continue to work on their 4-parent-line hybrid production model. If BAM-1 turns out to be good enough to abandon that model, I’d prefer he take up variants on spider silk silkworms instead of spending effort to develop a mundane silkworm production model that has a far lower profit margin.

Focus on your strengths, not on everything you might be able to do.

Until you have made your first substantial production cycle, you are still learning how to crawl.

Even if KBLB was capable of providing eggs for a thousand metric tons per year, don’t you think they would prefer a thousand tons of BAM-1/DS than eight hundred tons of mundane silk and 200 tons of BAM-1/DS.

Production costs will be about the same. Sales price for BAM-1/DS should be higher. Bigger markup = bigger profit.

KBLB may have done some useful work in developing disease resistant silkworms. But that can be done by other competitors. If it is a lucrative market, KBLB will have a lot of competition.

But let me ask you: What would you prefer? KBLB developing new and improved versions of DS, or developing mundane silkworms by crossing existing strains and breeding for disease resistance?

pr's can cost 400-500 bucks to $10k or more...it depends on how far a reach you want to pay for...and it also depends on how large the pr is....at a certain point you end up paying for each additional word...could be as much as $100 per additional word...and kim can get kinda wordy in some of his pr's, especially his letters to shareholders...

since Dec, kim has put out about 20 pr's...if kim wanted far reaching pr's, they could have cost us about $200k by now...the industry is aware of kblb and they read the pr's...Yahoo gets all of our pr's...

but the truth is, even as good as the last pr was, it only talks of progress and potential...that isnt going to get sophisticated investors to pour money into a 10 cent penny stock...results will...

when we have real tangible results such as tonnage, im sure the news will be spread far and wide...it could be argued that beginning with the last pr, we should be spreading the news farther and wider...no matter the cost...

these are part of the reasons i have said that kblb is really not on a lot of radars...and those who are aware of kblb are not buying hand over fist.....at least, not yet...

success is coming...investors will follow...along with a rise in the pps...

News still has not hit many outlets. When it does, there could very well be another push.

And that’s before the bigger news in the pipeline we are all waiting for more details on.

Tick tock..

W2R

It hit some source distribution outlets but not others. A big one that it did not reach was globenewswire. I think a lot of the big brokers use that to disseminate news. I know fidelity does. So for example , on fidelity I don’t see the press release , but on apple’s stock app i do , because they use 24/7 market news as their source.

I think Ben meant to say….

The next PR is going to be HUGE and you forget to ask about 5/6s PR because it was so insignificant to what is coming.

And we didn’t want to spend money on such a small PR. We are saving up for THE BIG ONE.

"Thank you for your feedback. I think that we corrected the issue, but that means the next release will be properly distributed. "

Does this mean forget yesterday's PR the next one will be OK???

That's total bullshit!!

I think the issue from yesterday needs to be corrected. Is the PR going to disappear next???

My response from Ben regarding yesterday's PR and why it was not listed on news outlets:

Thank you for your feedback. I think that we corrected the issue, but that means the next release will be properly distributed.

Best regards,

Ben Hansel

720.288.8495

Patrik, in my opinion probably correct. We know what Bam-1 can do. There will be Bam-2 two and more. Any of which can now be Made in America.

I don't think we will be included in the group released in May. That is for a different program I believe.

My thoughts are we are waiting for the Air Force not the DOD.

It’s a $bil DoD program for seed funding bioengineering companies to establish production infrastructure in the US. The RFI specifically mentioned Spider Silk. Kim submitted the application to the Air Force and put out a PR on it. You can find it……

Hi EOT,

Just wondering if I understand correctly the DOD money has to be domestically

In the good old USA and unless I’m wrong all Kblb sucesses are from Vietnam and

The spider silk rearing is from Vietnam so this doesn’t meet the criteria from

domestic production. Just curious,

Patrik

Hopefully Kim starts announcing brands and products now that he’s back, but keep an eye on DoD to start dropping qualified names. They said it starts in May….

Well stated rayocac812. He does have problems ... even with his true identity.

It is better to fail at originality than to succeed at imitation?

1. So quoting sayings is original? 2. If you are imitating someone that has consistently supported vision through the thick and thin, which of you has been a wet paper airplane? Succeeding at imitation is all in the choices of what you are imitating.

"When the mind is weak, circumstances become a problem. When the mind is stable, circumstances become a challenge. When the mind is strong, circumstances become opportunities."

You've got problems.

I called Fidelity to ask them why yesterday's PR was not on their website. Fidelity has always been up to date when it comes to KBLB news. They told me that yesterday's PR has not hit the news outlets like CNBC and financial brokers like Fidelity or Ameritrade. I find that very weird. So, I sent an email to Ben letting him know this. I will let you know what happens.

No matter what, shares of KBLB are still too damn cheap, yet some folks are still selling. Talk about doing the complete opposite of what they should be doing. For all the news we have had from Vietnam, the stock should be trading at .25 as a minimum which is more than a double from here. GO KBLB!

Scwab still hasn't updated the news releases. TD was much more reliable unfortunately.

Which broker allows KBLB trades

I think that yesturday strated the march up to the point of tens of cents .

Let see if voulme is high as well to back this idea also. long.

The Solical Media is on to KBLB after yestirdays PR -IMO

I tracked this for a while and it seemed Schwab corrected it. Mostly, when it was delayed, it was the next day the news hit their wires. So, today should be that day. Let's hope it works to aid in another push up!!!

It's been said, and aptly applies to Mr. T/KBLB:

"Commitment is the foundation of great accomplishments."

Hopefully the investors out there will stop looking at KBLB as a "roulette wheel" like you pointed out and more as a good investment for the mid-long run. imo.

Now that we have factes and data i hope KT could start sharing names, contracts , sums, that might give us an idea where the pps and company is going in the next few weeks and months a head.

Yesterday's pr about all the achievments is full of success, the pps downplayed with a minimum of volume still needed. It doesn't in zero reflect what this company has achieved now. The potential is enormous and it can't last long until it is revealed to the investing community. Knowing this comany now is a roulette wheel with 35 black and 1 red case, people just have to put their money in and let the wheel turn!

Yep , that’s the “boom” here. Sky’s the limit. All new ballgame 💰💰💰💰💰

I dunno about .25 cents but we should definitely be at at least .18 cents right now when comparing the Polartec bump and shares outstanding at the time of that pre-COVID bump to now. .18 seems to me to be a realistic bottom but clearly the market disagrees with both of us (today). Bigger news is coming though. ![]()

Each moth produces around 500 eggs so it won’t take long. No worries.

KBLB is on an upward trajectory that nobody can truly understand because today’s news was truly that breathtaking. Lam Dong is now not just the center of silk production in Vietnam, it may be the center of the future of silk production for the World. Do you want mundane eggs from some other country? Or do you want disease free eggs that will increase your cocoon yields and make you more money? As Kim said, it’s an entirely different ballgame now.

Yet the cut and paste twins dwell in the past and post texts from over a decade ago like two school girls sharing secrets from their diaries. Pathetic.

I suspect this project is on the back burner if it is still being considered at all.

The markup is higher.

KBLB does not appear to have the breeding pool necessary to support even a single metric ton of silk per breeding cycle.

Reaching that level and sustaining it represents a new challenge for KBLB

KBLB needs to learn how to walk. If it succeeds, it will learn how to run.

Thompson has tripped over his own ambitions too many times already.

“News still hasn't hit Schwab”

Not many have seen it yet.

Some excellent and thoughtful comments by posters that were initiated by clearly an optimistic PR that exudes confidence, indicates what is coming down the pike and says more in one news release then the last 6 or 7 releases. Honest assessments of where we are and could be heading is what is warranted today. Yet the cut and paste twins dwell in the past and post texts from over a decade ago like two school girls sharing secrets from their diaries. Pathetic.

Immunity worms were tested long ago

|

Followers

|

643

|

Posters

|

|

|

Posts (Today)

|

0

|

Posts (Total)

|

282780

|

|

Created

|

05/04/08

|

Type

|

Free

|

| Moderators gimmegimmeminemine TRUISM WebSlinger | |||

Email: corporate@KraigLabs.com

KRAIG LABS WEBSITE FOR INVESTORS

Quarterly and Annual Reporting to the SEC is available on the Company's Website and EDGAR.

* Financial Statements * SEC Filings *

Outstanding Shares as of January 12, 2023

For issues or questions relating to share certificates or the transfer of securities please contact the company's transfer agent:

Olde Monmouth Stock Transfer Co., Inc.

200 Memorial Pkwy.

Atlantic Highlands, New Jersey 07716

Phone: (732) 872-2727

(since August 14, 2013)

Kraig Biocraft Laboratories, Inc. (KBLB) is the first company with a commercially feasible spidersilk to be mass produced.

Kraig Labs is a biotechnology company focused on the development of commercially significant high performance polymers and technical fibers. Kraig Lab's focus has been on the production of a transgenic silkworm incorporating specific gene sequences from the golden orb weaving spider. These specific gene sequences inserted are to enable the silkworm to spin a new recombinant fiber which incorporates spider silk proteins. With the scientific breakthrough announced on September 29, 2010, Kraig Labs is now working to commercialize the transgenic silkworms to compete in the garment industry silk market. The value for the chinese raw silk market alone is 3-5 billion per annum. With the creation of 20 seperate transgenic silkworms, all with unique properties, Kraig Labs is now working at an accelerated pace to build upon their first generation transgenic organisms to develop their second generation of transgenic silkworm incorporating spider silk proteins. The scientists nearly doubled the strength of the silkworm with these specific spider gene insertions. Their second generation of transgenics are expected to be complete in 2011. These second generation organisms are to be compared with the strength, flexibility and resiliency of the native spider in which the gene sequences are derived from. These fibers which will match the strength of spider silk are expected to compete in the technical textiles market valued in excess of 120 billion per annum. The 3rd generation organisms are currently in the planning phase. These organisms are expected to spin fibers exceeding the strength of native spiders and may incorporate gene sequences that release an antibiotic, or to help reduce scarring with use in bandages.

Kraig Biocraft Laboratories has a sponsored research and development program with the University of Notre Dame, and the University of Wyoming. The genetic work is occurring at the University of Notre Dame, headed by Dr Malcolm Fraser, Phd. The gene sequences are derived from Dr. Randy Lewis's(University of Wyoming) patented gene sequences of the golden orb weaving spider. Kraig labs is paying for all expenses incurred for this research and development program, and thus Kraig Labs has exclusive global commercialization rights with the technologies developed, including methods, organisms, and fibers produced.

MANAGEMENT

Kim Thompson, Founder and CEO

As the CEO of the company, Mr. Thompson is the only member of the scientific advisory board who is also

a part of the corporation's management. His formal education lies in the fields of economics and law.

He received his B.A. in Applied Economics from James Madison College at Michigan State University.

He received his Juris Doctorate from the University of Michigan Law School in 1994.

Mr. Thompson founded Kraig Biocraft Laboratories in his pursuit of the development of new biotechnologies

with industrial applications. As chairman of the scientific advisory board, he brings a unique perspective,and

acts as the primary liaison between the advisory board and the corporation.

Mr. Thompson brings a wealth of experience in business management and consultation to Kraig. Following

the completion of his undergraduate degree, Mr. Thompson joined California Craftsman, Inc. as a

Vice-President with primary responsibility for both marketing and human resources.

Kim Thompson was the director of business development at Franchise Venture Partners, LLC. He subsequently

joined the firm of Shearson, Lehman, Hutton where he specialized in equity trading and research of small cap

companies. Mr. Thompson received the highest series seven score for all Shearson brokers in his class nationwide.

His experience in those small cap equity markets has proven to be invaluable both in his legal and business successes.

Prior to becoming a public company CEO, Mr. Thompson was the founder and senior litigation partner in a California

commercial law firm where he worked as corporate and litigation counsel to privately held and public companies.

His many accomplishments in corporate law include winning and collecting in full what his firm believes to have been

the largest award of lost profits in a California commercial arbitration up to that time. An important part of his work was

winning victories on behalf of corporate clients in disputes over intellectual property and distribution rights. He has

represented business clients ranging from small start ups and micro caps to Fortune 100 companies.

With a background in business leadership and in advising public and private corporations, Kim Thompson continues

to bring a unique perspective to the successful management of business. His extensive business and legal background

enables him to create practical solutions to business problems and seize opportunities for growth.

Mr. Thompson is a member of the Triple Nine Society for persons with documented genius level IQs (having tested above

the 99.9th percentile). He is also active in the realm of science and invention where he has to his credit a number of

provisional patent applications including innovations in the areas of biotechnology, organic polymers, genetic engineering

and magnetic field manipulation, among others.

Mr. Rice has over 13 years’ experience growing development stage businesses with a focus on technology development, commercialization, and go to market strategies. Mr. Rice holds a B.S. in Chemical engineering from Michigan Technological University.

Prior to joining Kraig Biocraft Laboratories Mr. Rice was the Director of Advanced Technologies for Ultra Electronics, AMI. In this role, Mr. Rice was responsible for the identification, capture, and execution of new technology programs. During his tenure with AMI, Rice secured more than twenty five million dollars in funded development programs from the US Department of Defense which his team successfully leveraged into commercially viable spinoff products. Mr. Rice was also responsible for technical sales, marketing, and promotion of AMI’s products and capabilities. Rice joined AMI as the third full time employee and helped to lead the organization through its rapid growth and ultimate acquisition by Ultra Electronics in 2011.

Earlier in his career Mr. Rice developed unique advanced manufacturing techniques, established and trained a production staff, led engineering development, authored numerous technical papers, and is a recognized subject matter expert. Mr. Rice holds 5 issued patents and numerous provisional patents.

Mr. Rice brings a history of transforming revolutionary ideas into viable commercial products.

Mr. Rice is currently completing his Masters of Business Administration through the Executive Program at the Eli Broad College of Business: Michigan State University.

Credit Randy Stewart

Credit Randy StewartDespite the huge potential of genetically modified animals outside of laboratory research, commercialisation of these animals has been extremely limited. Numerous factors, including negative consumer perception, regulatory hurdles, and limitations inherent to classical GM technologies, have kept the majority of GM animal applications within the realm of academic research. However genome editing using zinc finger nucleases could help develop new markets for the future commercialisation of GM animals.

Genetic modification is commonplace throughout the life sciences sector, from fundamental research to pharmaceutical testing. GM cellular and animal models are valuable tools for the study of many chronic diseases, the testing of pharmaceutical compounds and the development of new therapeutic strategies. Genetic modification also offers great benefits in vaccine and biopharmaceutical manufacturing, which rely heavily on the use of GM organisms for biomolecule design and production. Modifying the genome of an organism or cell line allows the incorporation of target biomolecules in specific biological contexts, as well as the transfer of a gene product from a low-producing organism to one that can produce on a commercial scale. These applications have been widely accepted for many years, with countless GM organisms approved for medical manufacturing applications by drug regulators in all major countries. Despite this widespread success within the research and pharmaceutical sectors, the use of GM organisms outside of these markets has been limited.

Despite the lack of broad acceptance for most commercial applications of GM animal products, this technology has been able to gain traction in a few market sectors. The most obvious application has been the commercialisation of transgenic animals for the production of biomolecules for therapeutic use. Cattle, sheep and goats have been used for large-scale production of antibodies, steroids and hormones - most notably insulin - for many years. In 2009, GTC Biotherapeutics received US FDA approval for bioproduction of a recombinant human antithrombin. This product - ATryn - is extracted from the milk of transgenic goats, and is the first approved biopharmaceutical to be produced using genetically engineered animals. Although this is a significant breakthrough for the commercialisation of GM animals, it is still within the pharmaceutical industry, and is a natural progression of existing cell-based technologies. Of potentially greater commercial interest is the extension of genetic engineering outside of this sector, into areas such as food production, textiles and even companion animals.

GM crops have been available in many countries since the early 1990s, and numerous cash crops - including sugar beet, soybean, corn and tomatoes - have been modified to improve resistance to disease, increase the rate of growth or enhance nutritional value. However, cultivation of these transgenic crops is generally tightly regulated, particularly within the European Union, and this, together with negative public opinion, has limited the more widespread development of GM technologies.

Similar to GM crops, many of the animals currently under development are intended to confer disease resistance, an application particularly suited to the use of zinc finger nuclease (ZFN) technology. Many diseases can be treated by the targeted deletion or modification of a host gene. With ZFNs, these targets can be modified with no footprint of genetic engineering. Due to the high costs of raising livestock, another area of focus in developing commercial GM animals has been increasing the rate of growth or size of animals. Among the first GM animals likely to be launched is a fast growing salmon from AquaBounty. The AquAdvantage Salmon is designed to reach market size in half the time of a wild type salmon, reducing costs for fish farmers and limiting the environmental impact of salmon farming by avoiding the need for ocean pens.

Although genetic engineering of animals for food is primarily driven by economic pressures, GM technologies have also been used in the companion animals market. In this sector, genetic modification can be used for practical purposes - such as the creation of hypoallergenic animals or the correction of heritable congenital defects which have arisen though inbreeding - or for purely cosmetic purposes, such as GloFish. The first example of a GM pet, GloFish are fluorescent zebrafish (Danio rerio) that have had genes encoding naturally fluorescent proteins (GFP, YFP, RFP) inserted into their genome. Developed by a group at the National University of Singapore, GloFish were originally created to develop live detection systems for water pollution. They were introduced as pets in the United States in 2003 following over two years of extensive environmental research and consultation. In Europe however, the sale and possession of GloFish is prohibited by rigorous legislation concerning the use of GM technologies.

By allowing precisely targeted insertion of spider genes and concomitant removal of endogenous silkworm silk genes at the same locus, ZFN technology offers the potential for development of transgenic silkworms which will produce native spider silk at commercially viable levels

Perhaps even more interesting from a commercial perspective is the use of GM animals in the manufacture of textiles. Silkworms - actually the larval form of the silkmoth Bombyx mori - have been used for the production of silk for thousands of years, with natural silk still produced by the cultivation of silkworms today. Silkworm cocoons are unwound to create linear silk threads, then re-spun into textiles in much the same way as cotton. Although the applications of silkworm silk are numerous, due to their unique physical and chemical properties, there is also widespread interest in the silks of several other insects.

Spider silk, in particular, offers numerous possibilities within the technical textiles industry, due to its incredible tensile strength and elasticity; characteristics which have not yet been replicated in synthetic materials. Like all insect silks, spider silk fibres consist of repetitive units of protein crystals separated by less structured protein chains. The exact properties and composition of each spider silk vary with its intended function. Major Ampullate or dragline silk, for example, is relatively hydrophobic with very high tensile strength and toughness, as it is used to form the outer rim and spokes of a web. In contrast, hydrophilic capture spiral silks, which form the inner structures of the web, are sticky and highly elastic to effectively entrap prey. This high degree of variability offers enormous potential for the textiles industry, raising the possibility of tailoring the properties of silk to create advanced technical fabrics, for applications such as bulletproof vests, parachute canopies and automobile airbags; biomedical applications, including sutures and tendon and ligament repair; new fabrics, for sportswear and clothing; and even microelectronics.

Although the use of spider silks for microsutures has recently been reported, more widespread application of spider silk technologies is currently limited by the difficulty in producing silks on a commercially viable scale. This is due to the difficulties of rearing spiders in large numbers, due to their highly territorial and cannibalistic nature. As a result, the harvesting of spider silk fibres is extremely time consuming and labour intensive, with production of the only known spider silk garment - an 11 foot by 4 foot shawl made from golden orb spider silk - taking 150 people over five years to produce and costing in excess of £300,000!

.

To overcome these limitations, and allow future development of spider silk technologies, an alternative strategy for spider silk production is required. This makes spider silk production an obvious candidate for genetic modification, inserting spider silk genes into the genome

of other silk-making insects for bioproduction. For example, random insertion of orb spider silk genes into silkworms has allowed production of hybrid spider/silkworm silk using traditional silkworm farming strategies. The resulting hybrid silk contains approximately 10% spider silk

and has greater strength and durability than native silkworm silk, raising the possibility of using transgenic silkworms to produce pure spider silks.

Though straightforward in principle, the exchange of native silkworm genes for spider silk genes, alongside more widespread exploitation of genetic engineering, has been limited by the inherent restrictions of conventional GM technologies.

The generalised process of modifying an organism requires several capabilities, including:

While many different techniques exist for accomplishing each of these steps, most GM technologies offer a compromise between the efficiency of the technique and the ability to accurately and precisely target the locus of interest. Viral genomic delivery technologies effectively deliver nucleic acids to cells and organisms, but fall short on ability to target specific regions of the genome, generally only allowing random insertion of genetic material. In comparison, transposase technologies allow a greater degree of targeting, but leave unwanted traces of exogenous DNA in their wake. Other methods involve the introduction of naked DNA into the cell, which results in insertion into the genome at very low frequencies, usually at random, limiting this approach to organisms that can be economically cultivated at high densities and screened in large numbers. Simply put, most techniques for genetic manipulation are random, inefficient and leave a 'footprint' of foreign DNA. While this is usually tolerated in basic research, it is not acceptable for most commercial applications, and has been a major hurdle for GM animal technologies to date.

The advent of zinc finger nuclease (ZFN) technology represents a significant breakthrough for commercialisation of GM animal products, offering precisely targeted, efficient genome editing for the first time. Commercially available through Sigma Life Science under the CompoZr brand, this technique can be used to create permanent and heritable changes to an organism of interest.

This high degree of variability offers enormous potential for the textiles industry, raising the possibility of tailoring the properties of silk to create advanced technical fabrics

ZFNs are a class of engineered DNA binding proteins that facilitate targeted editing of the genome by creating double-strand breaks at user-specified locations. These breaks stimulate the cell's natural DNA repair mechanisms - homologous recombination (HR) and non-homologous end joining (NHEJ) - which can be exploited to achieve rapid and permanent site-specific modification of the desired genes. While HR can be used to insert foreign DNA sequences, NHEJ allows the cell's natural processes to create precisely targeted mimics of natural mutations which leave no traces of foreign DNA. Unlike previous techniques, ZFNs offer excellent sequence specificity, binding 24 to 36 base pair target sequences to virtually eliminate off target effects, and are able to achieve modification rates exceeding 20 %, well above rates for most other technologies.

The technique is already being used to create transgenic silkworms for spider silk production. By allowing precisely targeted insertion of spider genes and concomitant removal of endogenous silkworm silk genes at the same locus, ZFN technology offers the potential for development of transgenic silkworms which will produce native spider silk at commercially viable levels.

GM technologies have revolutionised the research world and have great potential in a variety of commercial applications, but have been limited by the inherent restrictions associated with historical GM technologies. The main drawback of these technologies is their inability to accurately and efficiently target genes of interest, instead relying on random insertion of genetic material into host genomes. These limitations result in the need for extensive and costly screening to identify animals with correct transgene expression (without compromising the viability of the animal), and also result in the co-expression of both the transgene and native homologues already present.

The advent of ZFN technology signifies the beginning of an exciting new chapter in the world of genetic modification, allowing precise, targeted and efficient genome editing for the first time. Production of native spider silk using transgenic silkworms is just one example of the potential commercial applications of this innovative technology, taking us one step closer to the reality of industrial scale biomanufacturing and paving the way for an entirely new spectrum of environmentally friendly materials.

Authors:

Joseph Bedell and Brian Buntaine

Commercial Animal Technologies Group, Sigma Advanced Genetic Engineering (SAGE) Labs, Sigma Life Science

HEADLINES FOR KRAIG BIOCRAFT LABORATORIES / (KBLB):

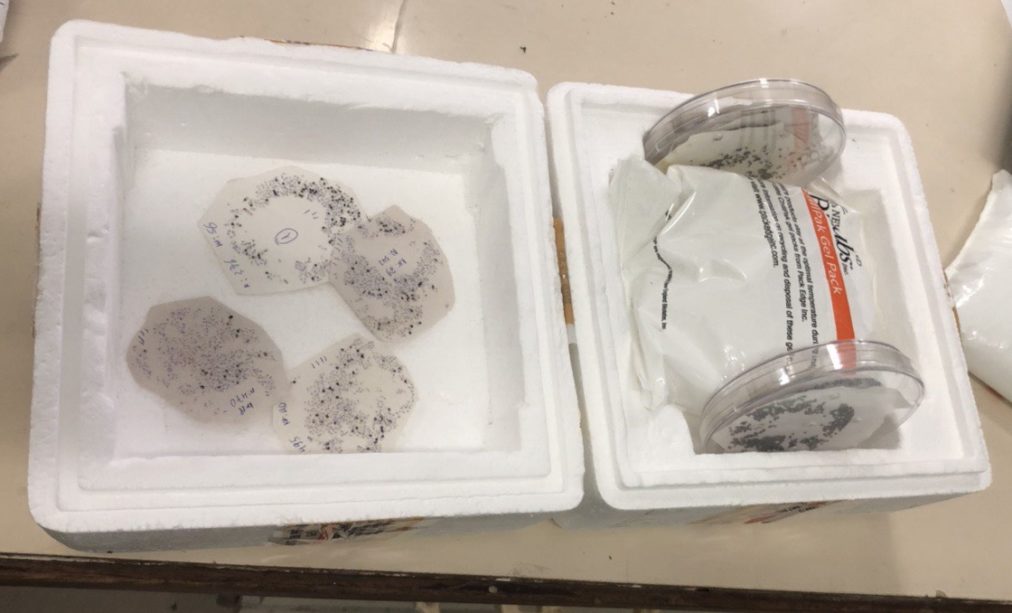

PHOTOS FROM VIETNAM POSTED JULY 6, 2018

ANN ARBOR, Mich., – January 7, 2019 –Kraig Biocraft Laboratories, Inc. (OTCQB: KBLB) (“Company”), the leading developer of spider silk based fibers, announces today that it has successfully delivered the first two shipments of its highly specialized silkworms, which produce a silk with the physical characteristics of spider silk, to Vietnam.

Today’s announcement is the culmination of more than 5 years of work, and challenging negotiation, with the government of Vietnam. The silkworms from these first two shipments have already hatched and are now enjoying a fresh mulberry diet, so, for the first time in history, the global demand for spider silk materials has a viable, cost effective, and scalable solution.

“The dream of commercializing our powerful technology is now materializing. This marks a dramatic leap forward in Kraig Labs’ business plan for commercial production and mass marketing of cost effective recombinant spider silk, and becomes the foundation for an entirely new industry,” said, COO, Jon Rice. “To our long-term shareholders, who have taken this journey with us, as well as our team in the US and Vietnam, who have worked tirelessly to make this dream a reality, I cannot thank you enough. As we start the New Year, full of new opportunity, we truly have something incredible to celebrate.”

The Company has been working with leading sericulture experts, biotechnology institutions, and governmental agencies, in Vietnam, to further boost the silk industry with our revolutionary technology. Kraig Labs is currently finalizing renovation plans for a ~46,000 square foot production factory in Quang Nam Province, Vietnam.

“Our plan has always been to bring our technology to the silk producing regions of the world for rapid scale-up,” said, CEO and Founder, Kim Thompson. “Today we see the fruits of that effort. With its massive silk infrastructure and production capacity, Vietnam is an ideal location to launch our technology scale-up. Congratulations to our team and shareholders, as we prepare for the realization of large scale production.”

\

\

| Volume | |

| Day Range: | |

| Bid Price | |

| Ask Price | |

| Last Trade Time: |