Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.

This has been an interesting week, that’s for sure. First, we get a blockbuster of a PR on monday, then on wednesday, or thereabouts, there is a “re-release” b/c there was a sorta/kinda snafu that prevented full distribution, then on friday we get a 247marketnews report that fleshed out the monday PR w/ the business end of it, i.e. - laying out all the markets our technology will transform, potentially speaking, of course. The end result being a strong surge in price action late afternoon friday pushing the SP nearly a full penny in about 30 minutes.

https://247marketnews.com/solutions/247

https://www.newsfilecorp.com/brochure/

247MarketNews did the report and released it 9:40am. And it was picked up by newsfile.com at 11am. The SP surge happened at around 3:30pm, about 6 hours time difference from the initial release. It seems curious how all this transpired, not that I’m complaining, mind you. Was this week coordinated, y’know, sorta…kinda…?

Many of us (excluding the you-know-who’s) are expecting news of a different sort, like news of a customer contract or at least news of revenue generating activity. Or maybe an announcement of signed agreements for those multiple production centers in multiple countries. I think it’s time for the first option. Given that PRs give info on situations already done, I would guess potential customers already knew about the production trial results before monday’s PR. That’s what NDAs are for.

That being the case, and I believe it is, the wheels of commerce are turning as we speak. Contracts are NOT negotiated over a weekend. I wonder how long it takes to FINALIZE a contract? All the work to setup the extensive infrastructure for production has been done w/ potential contracts in mind; farmers, reelers, etc. Again, this is what NDAs are for. On the first link above (247) they have this quote from George Bernard Shaw, "The Single Biggest Problem in Communication is the Illusion that it has taken Place.” Interesting. For Kraig, that ‘Illusion’ is gone. We are now 'known' and in the final countdown.

So, all the activity this week, was it random events, distribution mistakes, SNAFUs or was it a planned operation to ‘get the word out’ to potential investors, far and wide. I don’t know about the wednesday thing but the 247 report on friday was probably an appetizer (or prelude) to a monday PR announcing a contract. Who is responsible for the uptick in share buying from 3:30 to 4 pm is anybody’s guess. You couldn’t have scripted it any better than that. That report made sure our message got out there.

A quick take from the report. It mentioned the Textile market, alone, in 2020 was $1,000 Billion. That’s $1 Trillion! Not even talking about medical and/or licensing and/or the military/gov’t and/or whatever inroads into the plastics market we might make. That report on a friday buttressing a week that started w/ possibly the most impressive PR in the company’s history, culminating in a SP surge in the last 30 min. is powerful messaging.

“ … setting a new standard for the production of sustainable and high-performance materials … “

Now that BAM-1 tonnage production is well underway, Kim is back in the states finalizing apparel, medical, and Defensive material contracts. He has already negotiated with other countries to expand the foot print for DS production. Good times ahead….

As beacham would say “ BUY MORE SHARES”.

I know I have increased my share position over the last couple weeks.

$$$ KBLB$$$

The negative blabberings of the past and ridiculing the pangs of development, while getting off on the Risk Factors section of KBLB's filings, as if that's the only thing defining KBLB, will fade along with those touting them! That will be a time of pure bliss for us true KBLB supporters! I cannot wait!!!

"Imagine KBLB going up .04 in a week, yeah that's a bad week for webby"

The .04 isn't as important as the percentage of increase. But the news appears much more important than the .04.

To me webby has a job that looks to be near over. I'm glad to see him go.

Sounds like he is having some really bad days. His week is truly a nothing burger.

I would have been a Kong Jr.

Sounds like he is having some really bad days. His week is truly a nothing burger. He needs to plan his exit strategy. Doesn't look very good for his remaining days. He shouldn't really feel missed with the exception of the other two. They will be right behind him.

he also decided to forgo the usual stupid end of week cut and pastes such as the tired "nothing burger" bs...

Well he did miss the bus too 🤣. For the rest of us , keep your seatbelts fastened. We’re go for launch in T minus …..

Hey Webby.... lately you have omitted the bus verses sells. Why ???

YMIGH!!!! STAY TUNED!!!! GO KBLB!!!!

Good afternoon. Things are looking up, up, up. I really appreciate your putting info on ihub. Thank you again my friend.

Here’s a better link. The other doesn’t have the full article. I think many are missing it.

https://247marketnews.com/24-7-market-news-publishes-report-on-recent-spider-silk-production-breakthroughs-featuring-kraig-biocraft-laboratories/

I wonder if we will get a buying rush in anticipation of what we expect will be a good PR on Monday

In case people can’t open it…

24/7 Market News Publishes Report on Recent Spider Silk Production Breakthroughs Featuring Kraig Biocraft Laboratories

October 5, 2024 09:40

DENVER, Colo., May 10, 2024 (247marketnews.com)- Kraig Biocraft Laboratories (OTCQB:KBLB) and DuPont’s (NYSE:DD) are mentioned.

Spider Silk, the “Holy Grail” of Fibers, is coming and should Immediately Impact Several Significant Materials Sectors

The global mundane silk market is approximately $27.6 billion USD, as of 2023, and is expected to reach $52.6 billion, by 2029, according to Allied Market Research.

Spider silk is the toughest, which is a combination of strength and elasticity, fiber known to man.

Kraig Biocraft Laboratories (OTCQB:KBLB) is pioneering the production of genetically bioengineered spider silk, using silkworms modified to spin spider silk cocoons that can be harvested in commercial quantities.

Kraig Labs is employing existing conventional silk production and processing infrastructure to expedite expansion of its global production capabilities through partnerships and joint ventures.

Approximately 30 countries produce mundane silk, led by China, India, Japan, Thailand, Vietnam, and Brazil.

OTCQB:KBLB) is the leading developer of genetically engineered spider silk based fiber technologies." width="282" height="177" data-wp-pid="78415" /> Kraig Biocraft Laboratories (OTCQB:KBLB) is the leading developer of genetically engineered spider silk based fiber technologies.

However, before Kraig Labs’ bioengineered spider silk breakthroughs, there was no way to mass produce a high-quality version of this super fiber.

Spider silk’s tensile strength is comparable to high-grade steel and even stronger, in some cases, yet it elasticity allows it to stretch up to 5 times its length without breaking, so Kraig Labs’ Dragon Silk is even tougher than Kevlar, DuPont’s (NYSE:DD) antiballistic industry leading fiber.

Spider silk’s diverse potential applications should contribute to the growth of its future market value. It’s high-performance properties make it highly desired across various sectors including automotive, defense, healthcare, and textiles. For instance, in the automotive and defense sectors, spider silk’s high resilience and robustness make it an ideal material for manufacturing lighter and stronger components, such as bulletproof vests and other protective gear. The healthcare sector has experimented with innovative uses of spider silk, from biocompatible surgical sutures to other medical implants, leveraging its unique properties for various medical applications (Emergen Research)

The move towards producing spider silk at competitive costs could make it a viable alternative for Kevlar, plastics and other materials, especially considering its superior strength and biodegradability, but that transition could be expedited by the global focus on sustainability.

Non-Toxic Production: The production processes for many high-performance materials can be hazardous, involving toxic chemicals that pose health risks to workers. Biologically produced spider silk eliminates the need for harmful solvents and chemicals, promoting safer working conditions and improving the overall quality of life for those involved in the production chain.

Kraig Labs’ bio-degradable spider silk could significantly impact several markets by providing a sustainable alternative to traditional materials.

1. Wound Care: The global wound care market is extensive, with the demand driven by increasing cases of chronic wounds like diabetic ulcers and the rising number of surgeries. The market was valued at approximately $22.3 billion in 2023 and is expected to grow to around $31.7 billion by 2032, with a CAGR of about 4.51% during 2024-2032.

2. Textiles: While specific figures for eco-friendly or biodegradable textiles are less delineated, the global textile market size itself offers a perspective on potential. The market was valued at around $1000 billion in 2020 and is expected to grow substantially by the end of the decade, influenced by trends towards sustainability and innovative materials.

3. Medical Devices (specifically for wound care): This segment includes products like biodegradable sutures and meshes, where spider silk’s strength and compatibility could be particularly valuable. The advanced wound care products segment, a part of this market, is expected to see significant growth driven by innovations and an aging population susceptible to chronic wounds.

4. Protective Clothing: Including military and law enforcement gear, the market for personal protective equipment was valued at $52.7 billion in 2019 and is projected to reach $85.72 billion by 2027, potentially benefiting from materials like spider silk that offer high strength and flexibility.

*Grand View Research, Fortune Business Insights, Markets and Markets (source)

The integration of Kraig’s biodegradable spider silk into these markets could help reduce environmental impact significantly, replacing non-renewable, non-biodegradable materials like nylon and Kevlar. Moreover, the use of biodegradable materials aligns well with increasing regulatory and consumer demand for sustainable products, addressing several Environmental, Social, and Governance (ESG) concerns.

While specific financial metrics for Kraig Labs are not detailed in this report, the company’s investment appeal is enhanced by its innovative edge and potential to disrupt large, established markets with biodegradable alternatives. Financial incentives from governments and interest from industries seeking green alternatives could provide substantial revenue streams.

When Kraig Labs achieves its first commercial-size spider silk production run, the added value should be substantial, especially considering the following factors:

1. Market Positioning: Brining the first commercially viable bioengineered spider silk to market adds to Kraig Labs’ current leadership position in the next generation of advanced materials. This strengthened position should command premium pricing, especially in high-value markets like medical devices, aerospace, and defense.

2. Product Differentiation: Spider silk’s unique properties—such as its strength, flexibility, and biodegradability—offer significant advantages over traditional materials. This differentiation could allow Kraig Labs to penetrate various markets deeply, from textiles and apparel to more being specialized applications like surgical sutures and bulletproof vests.

3. Sustainability Appeal: Given the increasing consumer and corporate focus on sustainability, Kraig Labs’ ecofriendly spider silk could attract substantial interest from industries looking to improve their environmental footprint. This sustainability aspect could also open government subsidies or tax incentives, further enhancing its commercial value.

4. Scalability and Cost Efficiency: If Kraig Labs demonstrates that its spider silk can be produced on a commercial scale at a cost competitive with other high-performance fibers, this could rapidly accelerate adoption and increase the company’s market share in the materials sector.

5. Intellectual Property and Licensing: Many spider silk-based technologies will be patented, providing Kraig Labs with additional revenue streams through licensing agreements.

6. Collaborations: Commercial production could lead to strategic partnerships with major brands in various industries, enhancing Kraig Labs’ market reach and application spectrum.

Assuming successful scaling and market acceptance, for these fibers, the move to commercial production could significantly enhance Kraig Labs’ market capitalization, potentially by hundreds of millions of dollars, or more, depending on the scope and scale.

Kraig Labs just announced the completion of successful spring production trials. The company exclaimed, “These trials proved that the Company’s BAM-1 recombinant spider silk hybrids are ready for rapid production expansion. Simply stated, this has been the most fruitful and successful production cycle in the Company’s history.”

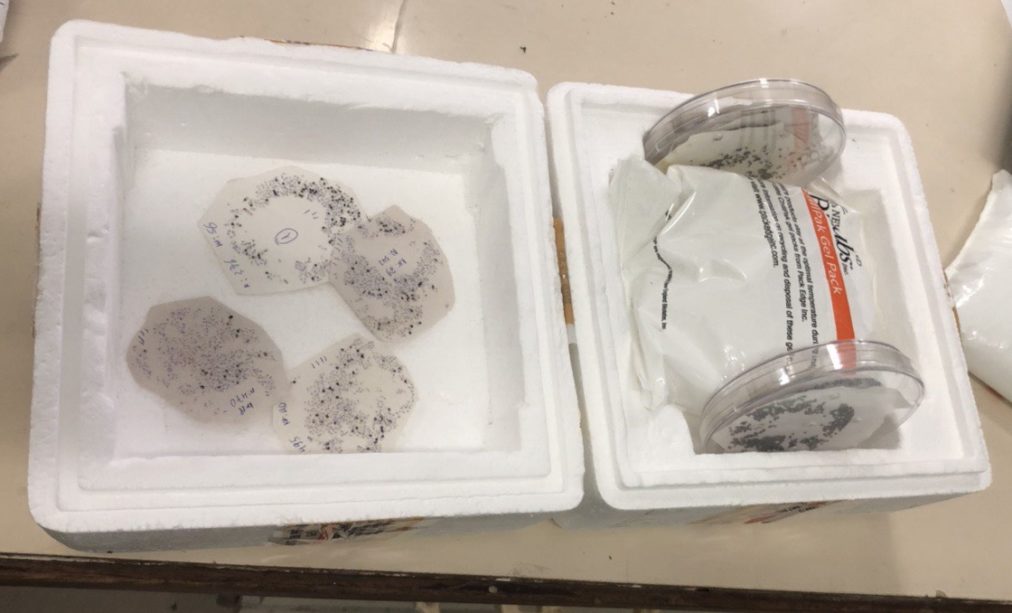

BAM 1 Cocoons from Kraig Labs Spring Spider Silk Production Trials, which yielded the Company’s most Fruitful and Successful Cycle

Observation and screening conducted throughout all phases of production exceeded all expectations for health and vigor within the colony. Not a single instance of disease or infection was detected at any point during the entire cycle. This result surprised local sericulture experts observing the trials. Working with mundane silkworms, they had never experienced an entire production cycle from egg to egg without any disease in a batch of thousands of silkworms.

“The BAM-1 parental lines have proven to be the strongest and most resilient we have ever fielded,” said Company founder and CEO, Kim Thompson. “This production run greatly exceeded our targets and has prepared us for the next phase of our business plan. With these production trials successfully concluded, we are now aggressively implementing the next phase of our business plan, which will expand our operations and target multiple production locations in multiple countries.”

Kraig Biocraft Laboratories’ spring production trials mark a groundbreaking moment in the field of material science and biotechnology. The company’s success in developing BAM-1 recombinant spider silk hybrids demonstrates not only the viability of their innovative approach but also sets the stage for significant scaling and commercial expansion. Thompson’s remarks underscore the importance of this milestone, highlighting the exceptional health and resilience of the BAM-1 lines throughout the production cycle—a feat never before seen by industry experts and a testament to the robustness of Kraig Labs’ genetic engineering capabilities.

This success propels Kraig Labs into the next phase of their strategic plan, which involves expanding operations across multiple countries. By doing so, they are not just increasing their production capacity but are also setting a new standard for the production of sustainable and high-performance materials. The implications of this expansion are profound, promising to meet the increasing demands for environmentally friendly materials in various industries worldwide. As Kraig Labs moves forward with its ambitious plans, it remains a key player to watch in the revolution of sustainable materials.

Excellent, DH. I am elated that the world is learning all about KBLB. Glad all these news wires have picked this up. Yahoo is huge. GO KBLB!

Phenomenal article, Money. Glad the word is getting out. Thank you! GO KBLB! ![]()

"If DS were to make a dent in the global textile market"

it isnt necessary for kblb to make a dent in the global TEXTILE market...they are trying to get a foot hold on the silk market and hopefully dominate that in one way or another...and they also want to enter the technical and medical fiber markets...the military...

kblb isnt interested in cornering the t-shirt market...they arent interested in competing with fruit of the loom...they will enter the fashion industry with LUXURY street wear...easy and quick money as well as cheap advertising...then on to the others...

"If that were to happen, it would take decades."

i dont believe that is the goal so, it is irrelevant...

" I’m not expecting to live long enough to see KBLB’s world domination"

again, not the goal...thats China's goal and they will eventually be the global leader...

if kblb stays on course and keeps progressing as they are now, we will all be very happy with the pps....we have no need to do most of what you are talking about...and it isnt necessary for success...

In the last letter Kim mentioned a hold on marketing Spydasilk, many other partners like Warwick Mills and Polartech should be Include….. until production was proven.

Now that Kim is back from Vietnam exceedingly happy… can’t wait for the next update!!!

KBLB….let’s shift to marketing!!

i LOVE this quote:

"This success propels Kraig Labs into the next phase of their strategic plan, which involves expanding operations across multiple countries. By doing so, they are not just increasing their production capacity but are also setting a new standard for the production of sustainable and high-performance materials. The implications of this expansion are profound, promising to meet the increasing demands for environmentally friendly materials in various industries worldwide. As Kraig Labs moves forward with its ambitious plans, it remains a key player to watch in the revolution of sustainable materials."

Over $1.12 by 6/30.

I’m calling it.

Yahoo picked it up

https://finance.yahoo.com/news/24-7-market-news-publishes-150100637.html

If you thought the last PR was mind-blowin', you gotta read this report. There is too, too much to quote. How many potential investors will read this? After reading this, the organic move to NASDAQ is practically a certainty.

Outstanding find, M4N. thank you muchly.

As if your life depended on it ... BUY MORE SHARES

Later, WBeacham

Trust takes years to build, seconds to break, and forever to repair.” … the KBLB way.

… the KBLB way.

“What will the share price be when the company announces metric tonnage monthly production, delivery to Kings, revenues received and additional contracts signed with bigger name entities?“

With Military and Medical products-supply contracts…..

My guess is well into high $dollars per share. Quick

KBLB…. The worlds first SPIDER SILK!! Is ready.

An Easy Organic uplist…

I don’t believe the filing says “must happen at today’s share price”.

The uplist will happen AFTER mass production is confirmed, IMO.

What will the share price be when the company announces metric tonnage monthly production, delivery to Kings, revenues received and additional contracts signed with bigger name entities?

The company intends to raise $$ to support further expansion into multiple countries, increase production, fulfill more orders and exponentially grow shareholder value?

How dare they..

![]()

The uplist was never the main focus. The Douchebag CEO was losing voting control of the company and wanted to seize control via reverse splitting the shares of (except his super voting shares) which would have essentially given him 95%+ of the vote.

Why not sell out and buy a poly stock? Then no worries. And no crying all day every day because you are unhappy. I think you will have a good exit opportunity next week.

"Polyester and nylon are cheaper to produce than Pima cotton and much much cheaper than silk. "

<< Kraig Biocraft Laboratories (OTCQB:KBLB) has updated its filing with the SEC for a proposed $10M offering and uplisting to Nasdaq. >>

In other words, MASSIVE dilution.

At today's share price, that would equate to another 82 MILLION shares.

Yes, the price would have slumped, but Thompson also lost additional credibility among investors, who recognized that his uplist plan was premature and badly executed.

“Trust takes years to build, seconds to break, and forever to repair.” … the KBLB way.

Polyester and nylon are cheaper to produce than Pima cotton and much much cheaper than silk. Society has a way of ignoring the hidden costs associated with products, which is why we still have coal- and gas-fired electric generation and gas stoves, in spite of the carbon footprint. The list of such offenders is long.

In 2022, the global production of polyester and nylon fibers was 87,000,000 metric tons. Global production of wool and cotton was 27,000,000 metric tons. Global production of silk was 91,221 metric tons.

If DS were to make a dent in the global textile market, it would have to replace all mundane silk production worldwide and then increase global silk production by a factor of 100.

If that were to happen, it would take decades.

Assuming KBLB is successful in producing and selling their silk, hopefully they will find sufficient markets to fuel rapid growth and we all become rich beyond our wildest dreams. I’m not expecting to live long enough to see KBLB’s world domination. It would be great to see some luxury hoodies and sports apparel. I’d even settle for a silk tie right now, but hopefully not one as ugly as BOLT made.

I accessed it for free from the Stock Day Media site. Scroll down to the date Wed Nov 22nd, 2023 and you can access from that link w/o any registration.

Note: I know it's dated on Nov 2023. The fact we DID update is noteworthy.

Kraig Biocraft updates filing for proposed uplisting, $10M offering

Nov. 22, 2023 5:58 PM ETKraig Biocraft Laboratories, Inc. (KBLB)

Kraig Biocraft Laboratories (OTCQB:KBLB) has updated its filing with the SEC for a proposed $10M offering and uplisting to Nasdaq.

Kraig said in its latest filing that it was looking to offer 1.9M units in the range of $4.25 to $6.25, with an assumed price of $5.25. Each unit would consist of one common share plus one warrant to buy one common share for the assumed price of $5.25.

Underwriters would be granted a 45-day option to buy up to 286K additional shares and/or warrants. Maxim Group is serving as sole bookrunner.

Kraig’s shares are currently traded OTC under the symbol KBLB. The company hopes to list them on Nasdaq or another national exchange under the same symbol.

Based in Michigan, Kraig Biocraft uses recombinant DNA technology to create high-strength fibers for the technical textile and specialty fiber sectors.

Could you post the article about the Nasdaq? It won't let me read it without a subscription

Seeking Alpha article is dated Nov 22 2023.

Like a famous comedian once said, 'There is no such thing as an old joke, just an old audience.'.

This company is the cheapest goldmine on Earth.

I really like that we are getting airtime on Stock Day Media. Go to the link below, scroll around, see that we have been featured on a regular basis on the PR days - e.g. - Notable News, Penny Stocks worth trading, Overlookded stocks under $1, etc. We are getting noticed in a very big way. Those who claim we are not ‘known’ have no idea what they are talking about. We are a volcano ready to blow. Think Mt. Vesuvius.

https://stockdaymedia.com/research-profile/?symbol=KBLB

I think I may have missed this. We updated our filing for NASDAQ IPO listing?

https://seekingalpha.com/news/4039774-kraig-biocraft-updates-filing-for-proposed-uplisting-10m-offering?utm_source=quotemedia.com&utm_medium=referral&feed_item_type=news

Don’t argue, geez … BUY MORE SHARES !!!

We are the NEXT BIG THING. FULL STOP.

Later, WBeacham

It went to 50 in the first place because of 1 word, "Polartec". Then it crashed because of 2 words, "reverse split". At least that's how I remember it. What we need now is several names dropped. Hopefully after the first commercial batch is shipped, he'll mention the names of other companies that are in the queue to receive silk.

So great for KBLB to be mentioned in that video, Silk. Thanks for this information! GO KBLB!

Indonesia relies way too much on imported silkworm and as a result their sericulture industry is declining. Seems they have mulberry challenges as well, so maybe not ideal. But I wonder if Indonesia has expressed interest in KBLB’s technology. Based on Dr. Kumar’s involvement, I expect India is next. But Indonesia seems like another possibility. I don’t see any connections other than they have a need to reverse the decline.

This may be of interest to you:

https://www.thejakartapost.com/indonesia/2023/11/01/indonesia-increasingly-reliant-on-imported-silkworms-researcher.html

Translation from Hindi: “How is the silkworm born? How is silk made?”

Even if you do not understand Hindi, this is one of the best videos I have seen with beautiful videos on silk production, moths, and silkworm eggs. Just ignore the “Made in China” at the beginning and watch to the end. I guarantee you’ll learn or see something new about silkworm production just by watching. Best footage of moths I’ve ever seen:

Hopefully cocoons become metric tons which turns into revenue by the end of the year. Then you might see an organic pps rise that makes it seamless without the need for any talk about NASDAQ or that other forbidden two word phrase. I hope they’ve finally learned to talk with production results instead. Because the current strategy is working better and will work better than anything they’ve ever done. The big difference between back then and now is that they can finally deliver on metric ton production. At least it seems like KBLB is finally on the verge of producing metric tonnage and growing capacity. The sooner KBLB can start getting these fibers and yarns to market, the sooner the industry is going to help figure out how best to use them and make money off of them. Everyone should be excited about that.

By the way, I just read a Feb article on PVA’s in laundry and dishwasher detergent pods and it reminded me again of just how big KBLB’s silkworms are going to be in curbing microplastics in our water supply. Poly fibers will never be replaced, but when given a choice, there are many who will go for clothes made of natural fibers if everything else is equal. The real question that remains is what poly fibers can and will KBLB replace based on cost and performance. Cheaper? I dunno. Stronger? Check. I can’t wait to see. Even a blended fabric is better for the environment than a 100% poly fabric. But a 100% spidersilk or the Pima cotton spidersilk blend are even better. This stuff will be and supposedly is in high demand so once they start making a lot of it they’ll hit more targets than we can see right now. Nothing I haven’t already dreamed and thought about for over a decade. Time for dreams to come true!!!!!

It was premature and a poor decision by the CEO at the time.

Which has been confirmed by the lack of production since the uplist plan.

That being said, the share price would have slumped anyways as the imminent production the company portrayed never came.

Stock Day Media:

Kraig Biocraft Laboratories, Inc. (OTCQB: KBLB), announces it has now taken possession of its new recombinant spider silk production center in Lam Dong Province, Vietnam. This new facility is located in the heart of Vietnam’s booming silk economy and will serve as the center of operations for the Company’s growing spider silk production in 2024.

So we all knew continuous production at mass commercialization levels was not ready at the time and that the share price would have resumed at its "normal" levels, but, some still prefer to tout an uplist plan as the reason for the Crash. Lol. Those are the people who should not be invested in developmental companies! SMDH

In mid 2019, the SP reached $0.45, or so. Primarily, it happened on the prospect of uplisting to a better exchange, presumably NASDAQ

Well done, Beacham! You are spot on again! Loved your analysis of how KBLB is undervalued by three times! Shares are still dirt cheap. Always great to see you posting. GO KBLB! ![]()

|

Followers

|

643

|

Posters

|

|

|

Posts (Today)

|

1

|

Posts (Total)

|

282554

|

|

Created

|

05/04/08

|

Type

|

Free

|

| Moderators gimmegimmeminemine TRUISM WebSlinger | |||

Email: corporate@KraigLabs.com

KRAIG LABS WEBSITE FOR INVESTORS

Quarterly and Annual Reporting to the SEC is available on the Company's Website and EDGAR.

* Financial Statements * SEC Filings *

Outstanding Shares as of January 12, 2023

For issues or questions relating to share certificates or the transfer of securities please contact the company's transfer agent:

Olde Monmouth Stock Transfer Co., Inc.

200 Memorial Pkwy.

Atlantic Highlands, New Jersey 07716

Phone: (732) 872-2727

(since August 14, 2013)

Kraig Biocraft Laboratories, Inc. (KBLB) is the first company with a commercially feasible spidersilk to be mass produced.

Kraig Labs is a biotechnology company focused on the development of commercially significant high performance polymers and technical fibers. Kraig Lab's focus has been on the production of a transgenic silkworm incorporating specific gene sequences from the golden orb weaving spider. These specific gene sequences inserted are to enable the silkworm to spin a new recombinant fiber which incorporates spider silk proteins. With the scientific breakthrough announced on September 29, 2010, Kraig Labs is now working to commercialize the transgenic silkworms to compete in the garment industry silk market. The value for the chinese raw silk market alone is 3-5 billion per annum. With the creation of 20 seperate transgenic silkworms, all with unique properties, Kraig Labs is now working at an accelerated pace to build upon their first generation transgenic organisms to develop their second generation of transgenic silkworm incorporating spider silk proteins. The scientists nearly doubled the strength of the silkworm with these specific spider gene insertions. Their second generation of transgenics are expected to be complete in 2011. These second generation organisms are to be compared with the strength, flexibility and resiliency of the native spider in which the gene sequences are derived from. These fibers which will match the strength of spider silk are expected to compete in the technical textiles market valued in excess of 120 billion per annum. The 3rd generation organisms are currently in the planning phase. These organisms are expected to spin fibers exceeding the strength of native spiders and may incorporate gene sequences that release an antibiotic, or to help reduce scarring with use in bandages.

Kraig Biocraft Laboratories has a sponsored research and development program with the University of Notre Dame, and the University of Wyoming. The genetic work is occurring at the University of Notre Dame, headed by Dr Malcolm Fraser, Phd. The gene sequences are derived from Dr. Randy Lewis's(University of Wyoming) patented gene sequences of the golden orb weaving spider. Kraig labs is paying for all expenses incurred for this research and development program, and thus Kraig Labs has exclusive global commercialization rights with the technologies developed, including methods, organisms, and fibers produced.

MANAGEMENT

Kim Thompson, Founder and CEO

As the CEO of the company, Mr. Thompson is the only member of the scientific advisory board who is also

a part of the corporation's management. His formal education lies in the fields of economics and law.

He received his B.A. in Applied Economics from James Madison College at Michigan State University.

He received his Juris Doctorate from the University of Michigan Law School in 1994.

Mr. Thompson founded Kraig Biocraft Laboratories in his pursuit of the development of new biotechnologies

with industrial applications. As chairman of the scientific advisory board, he brings a unique perspective,and

acts as the primary liaison between the advisory board and the corporation.

Mr. Thompson brings a wealth of experience in business management and consultation to Kraig. Following

the completion of his undergraduate degree, Mr. Thompson joined California Craftsman, Inc. as a

Vice-President with primary responsibility for both marketing and human resources.

Kim Thompson was the director of business development at Franchise Venture Partners, LLC. He subsequently

joined the firm of Shearson, Lehman, Hutton where he specialized in equity trading and research of small cap

companies. Mr. Thompson received the highest series seven score for all Shearson brokers in his class nationwide.

His experience in those small cap equity markets has proven to be invaluable both in his legal and business successes.

Prior to becoming a public company CEO, Mr. Thompson was the founder and senior litigation partner in a California

commercial law firm where he worked as corporate and litigation counsel to privately held and public companies.

His many accomplishments in corporate law include winning and collecting in full what his firm believes to have been

the largest award of lost profits in a California commercial arbitration up to that time. An important part of his work was

winning victories on behalf of corporate clients in disputes over intellectual property and distribution rights. He has

represented business clients ranging from small start ups and micro caps to Fortune 100 companies.

With a background in business leadership and in advising public and private corporations, Kim Thompson continues

to bring a unique perspective to the successful management of business. His extensive business and legal background

enables him to create practical solutions to business problems and seize opportunities for growth.

Mr. Thompson is a member of the Triple Nine Society for persons with documented genius level IQs (having tested above

the 99.9th percentile). He is also active in the realm of science and invention where he has to his credit a number of

provisional patent applications including innovations in the areas of biotechnology, organic polymers, genetic engineering

and magnetic field manipulation, among others.

Mr. Rice has over 13 years’ experience growing development stage businesses with a focus on technology development, commercialization, and go to market strategies. Mr. Rice holds a B.S. in Chemical engineering from Michigan Technological University.

Prior to joining Kraig Biocraft Laboratories Mr. Rice was the Director of Advanced Technologies for Ultra Electronics, AMI. In this role, Mr. Rice was responsible for the identification, capture, and execution of new technology programs. During his tenure with AMI, Rice secured more than twenty five million dollars in funded development programs from the US Department of Defense which his team successfully leveraged into commercially viable spinoff products. Mr. Rice was also responsible for technical sales, marketing, and promotion of AMI’s products and capabilities. Rice joined AMI as the third full time employee and helped to lead the organization through its rapid growth and ultimate acquisition by Ultra Electronics in 2011.

Earlier in his career Mr. Rice developed unique advanced manufacturing techniques, established and trained a production staff, led engineering development, authored numerous technical papers, and is a recognized subject matter expert. Mr. Rice holds 5 issued patents and numerous provisional patents.

Mr. Rice brings a history of transforming revolutionary ideas into viable commercial products.

Mr. Rice is currently completing his Masters of Business Administration through the Executive Program at the Eli Broad College of Business: Michigan State University.

Credit Randy Stewart

Credit Randy StewartDespite the huge potential of genetically modified animals outside of laboratory research, commercialisation of these animals has been extremely limited. Numerous factors, including negative consumer perception, regulatory hurdles, and limitations inherent to classical GM technologies, have kept the majority of GM animal applications within the realm of academic research. However genome editing using zinc finger nucleases could help develop new markets for the future commercialisation of GM animals.

Genetic modification is commonplace throughout the life sciences sector, from fundamental research to pharmaceutical testing. GM cellular and animal models are valuable tools for the study of many chronic diseases, the testing of pharmaceutical compounds and the development of new therapeutic strategies. Genetic modification also offers great benefits in vaccine and biopharmaceutical manufacturing, which rely heavily on the use of GM organisms for biomolecule design and production. Modifying the genome of an organism or cell line allows the incorporation of target biomolecules in specific biological contexts, as well as the transfer of a gene product from a low-producing organism to one that can produce on a commercial scale. These applications have been widely accepted for many years, with countless GM organisms approved for medical manufacturing applications by drug regulators in all major countries. Despite this widespread success within the research and pharmaceutical sectors, the use of GM organisms outside of these markets has been limited.

Despite the lack of broad acceptance for most commercial applications of GM animal products, this technology has been able to gain traction in a few market sectors. The most obvious application has been the commercialisation of transgenic animals for the production of biomolecules for therapeutic use. Cattle, sheep and goats have been used for large-scale production of antibodies, steroids and hormones - most notably insulin - for many years. In 2009, GTC Biotherapeutics received US FDA approval for bioproduction of a recombinant human antithrombin. This product - ATryn - is extracted from the milk of transgenic goats, and is the first approved biopharmaceutical to be produced using genetically engineered animals. Although this is a significant breakthrough for the commercialisation of GM animals, it is still within the pharmaceutical industry, and is a natural progression of existing cell-based technologies. Of potentially greater commercial interest is the extension of genetic engineering outside of this sector, into areas such as food production, textiles and even companion animals.

GM crops have been available in many countries since the early 1990s, and numerous cash crops - including sugar beet, soybean, corn and tomatoes - have been modified to improve resistance to disease, increase the rate of growth or enhance nutritional value. However, cultivation of these transgenic crops is generally tightly regulated, particularly within the European Union, and this, together with negative public opinion, has limited the more widespread development of GM technologies.

Similar to GM crops, many of the animals currently under development are intended to confer disease resistance, an application particularly suited to the use of zinc finger nuclease (ZFN) technology. Many diseases can be treated by the targeted deletion or modification of a host gene. With ZFNs, these targets can be modified with no footprint of genetic engineering. Due to the high costs of raising livestock, another area of focus in developing commercial GM animals has been increasing the rate of growth or size of animals. Among the first GM animals likely to be launched is a fast growing salmon from AquaBounty. The AquAdvantage Salmon is designed to reach market size in half the time of a wild type salmon, reducing costs for fish farmers and limiting the environmental impact of salmon farming by avoiding the need for ocean pens.

Although genetic engineering of animals for food is primarily driven by economic pressures, GM technologies have also been used in the companion animals market. In this sector, genetic modification can be used for practical purposes - such as the creation of hypoallergenic animals or the correction of heritable congenital defects which have arisen though inbreeding - or for purely cosmetic purposes, such as GloFish. The first example of a GM pet, GloFish are fluorescent zebrafish (Danio rerio) that have had genes encoding naturally fluorescent proteins (GFP, YFP, RFP) inserted into their genome. Developed by a group at the National University of Singapore, GloFish were originally created to develop live detection systems for water pollution. They were introduced as pets in the United States in 2003 following over two years of extensive environmental research and consultation. In Europe however, the sale and possession of GloFish is prohibited by rigorous legislation concerning the use of GM technologies.

By allowing precisely targeted insertion of spider genes and concomitant removal of endogenous silkworm silk genes at the same locus, ZFN technology offers the potential for development of transgenic silkworms which will produce native spider silk at commercially viable levels

Perhaps even more interesting from a commercial perspective is the use of GM animals in the manufacture of textiles. Silkworms - actually the larval form of the silkmoth Bombyx mori - have been used for the production of silk for thousands of years, with natural silk still produced by the cultivation of silkworms today. Silkworm cocoons are unwound to create linear silk threads, then re-spun into textiles in much the same way as cotton. Although the applications of silkworm silk are numerous, due to their unique physical and chemical properties, there is also widespread interest in the silks of several other insects.

Spider silk, in particular, offers numerous possibilities within the technical textiles industry, due to its incredible tensile strength and elasticity; characteristics which have not yet been replicated in synthetic materials. Like all insect silks, spider silk fibres consist of repetitive units of protein crystals separated by less structured protein chains. The exact properties and composition of each spider silk vary with its intended function. Major Ampullate or dragline silk, for example, is relatively hydrophobic with very high tensile strength and toughness, as it is used to form the outer rim and spokes of a web. In contrast, hydrophilic capture spiral silks, which form the inner structures of the web, are sticky and highly elastic to effectively entrap prey. This high degree of variability offers enormous potential for the textiles industry, raising the possibility of tailoring the properties of silk to create advanced technical fabrics, for applications such as bulletproof vests, parachute canopies and automobile airbags; biomedical applications, including sutures and tendon and ligament repair; new fabrics, for sportswear and clothing; and even microelectronics.

Although the use of spider silks for microsutures has recently been reported, more widespread application of spider silk technologies is currently limited by the difficulty in producing silks on a commercially viable scale. This is due to the difficulties of rearing spiders in large numbers, due to their highly territorial and cannibalistic nature. As a result, the harvesting of spider silk fibres is extremely time consuming and labour intensive, with production of the only known spider silk garment - an 11 foot by 4 foot shawl made from golden orb spider silk - taking 150 people over five years to produce and costing in excess of £300,000!

.

To overcome these limitations, and allow future development of spider silk technologies, an alternative strategy for spider silk production is required. This makes spider silk production an obvious candidate for genetic modification, inserting spider silk genes into the genome

of other silk-making insects for bioproduction. For example, random insertion of orb spider silk genes into silkworms has allowed production of hybrid spider/silkworm silk using traditional silkworm farming strategies. The resulting hybrid silk contains approximately 10% spider silk

and has greater strength and durability than native silkworm silk, raising the possibility of using transgenic silkworms to produce pure spider silks.

Though straightforward in principle, the exchange of native silkworm genes for spider silk genes, alongside more widespread exploitation of genetic engineering, has been limited by the inherent restrictions of conventional GM technologies.

The generalised process of modifying an organism requires several capabilities, including:

While many different techniques exist for accomplishing each of these steps, most GM technologies offer a compromise between the efficiency of the technique and the ability to accurately and precisely target the locus of interest. Viral genomic delivery technologies effectively deliver nucleic acids to cells and organisms, but fall short on ability to target specific regions of the genome, generally only allowing random insertion of genetic material. In comparison, transposase technologies allow a greater degree of targeting, but leave unwanted traces of exogenous DNA in their wake. Other methods involve the introduction of naked DNA into the cell, which results in insertion into the genome at very low frequencies, usually at random, limiting this approach to organisms that can be economically cultivated at high densities and screened in large numbers. Simply put, most techniques for genetic manipulation are random, inefficient and leave a 'footprint' of foreign DNA. While this is usually tolerated in basic research, it is not acceptable for most commercial applications, and has been a major hurdle for GM animal technologies to date.

The advent of zinc finger nuclease (ZFN) technology represents a significant breakthrough for commercialisation of GM animal products, offering precisely targeted, efficient genome editing for the first time. Commercially available through Sigma Life Science under the CompoZr brand, this technique can be used to create permanent and heritable changes to an organism of interest.

This high degree of variability offers enormous potential for the textiles industry, raising the possibility of tailoring the properties of silk to create advanced technical fabrics

ZFNs are a class of engineered DNA binding proteins that facilitate targeted editing of the genome by creating double-strand breaks at user-specified locations. These breaks stimulate the cell's natural DNA repair mechanisms - homologous recombination (HR) and non-homologous end joining (NHEJ) - which can be exploited to achieve rapid and permanent site-specific modification of the desired genes. While HR can be used to insert foreign DNA sequences, NHEJ allows the cell's natural processes to create precisely targeted mimics of natural mutations which leave no traces of foreign DNA. Unlike previous techniques, ZFNs offer excellent sequence specificity, binding 24 to 36 base pair target sequences to virtually eliminate off target effects, and are able to achieve modification rates exceeding 20 %, well above rates for most other technologies.

The technique is already being used to create transgenic silkworms for spider silk production. By allowing precisely targeted insertion of spider genes and concomitant removal of endogenous silkworm silk genes at the same locus, ZFN technology offers the potential for development of transgenic silkworms which will produce native spider silk at commercially viable levels.

GM technologies have revolutionised the research world and have great potential in a variety of commercial applications, but have been limited by the inherent restrictions associated with historical GM technologies. The main drawback of these technologies is their inability to accurately and efficiently target genes of interest, instead relying on random insertion of genetic material into host genomes. These limitations result in the need for extensive and costly screening to identify animals with correct transgene expression (without compromising the viability of the animal), and also result in the co-expression of both the transgene and native homologues already present.

The advent of ZFN technology signifies the beginning of an exciting new chapter in the world of genetic modification, allowing precise, targeted and efficient genome editing for the first time. Production of native spider silk using transgenic silkworms is just one example of the potential commercial applications of this innovative technology, taking us one step closer to the reality of industrial scale biomanufacturing and paving the way for an entirely new spectrum of environmentally friendly materials.

Authors:

Joseph Bedell and Brian Buntaine

Commercial Animal Technologies Group, Sigma Advanced Genetic Engineering (SAGE) Labs, Sigma Life Science

HEADLINES FOR KRAIG BIOCRAFT LABORATORIES / (KBLB):

PHOTOS FROM VIETNAM POSTED JULY 6, 2018

ANN ARBOR, Mich., – January 7, 2019 –Kraig Biocraft Laboratories, Inc. (OTCQB: KBLB) (“Company”), the leading developer of spider silk based fibers, announces today that it has successfully delivered the first two shipments of its highly specialized silkworms, which produce a silk with the physical characteristics of spider silk, to Vietnam.

Today’s announcement is the culmination of more than 5 years of work, and challenging negotiation, with the government of Vietnam. The silkworms from these first two shipments have already hatched and are now enjoying a fresh mulberry diet, so, for the first time in history, the global demand for spider silk materials has a viable, cost effective, and scalable solution.

“The dream of commercializing our powerful technology is now materializing. This marks a dramatic leap forward in Kraig Labs’ business plan for commercial production and mass marketing of cost effective recombinant spider silk, and becomes the foundation for an entirely new industry,” said, COO, Jon Rice. “To our long-term shareholders, who have taken this journey with us, as well as our team in the US and Vietnam, who have worked tirelessly to make this dream a reality, I cannot thank you enough. As we start the New Year, full of new opportunity, we truly have something incredible to celebrate.”

The Company has been working with leading sericulture experts, biotechnology institutions, and governmental agencies, in Vietnam, to further boost the silk industry with our revolutionary technology. Kraig Labs is currently finalizing renovation plans for a ~46,000 square foot production factory in Quang Nam Province, Vietnam.

“Our plan has always been to bring our technology to the silk producing regions of the world for rapid scale-up,” said, CEO and Founder, Kim Thompson. “Today we see the fruits of that effort. With its massive silk infrastructure and production capacity, Vietnam is an ideal location to launch our technology scale-up. Congratulations to our team and shareholders, as we prepare for the realization of large scale production.”

\

\

| Volume | |

| Day Range: | |

| Bid Price | |

| Ask Price | |

| Last Trade Time: |