Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.

Upcoming Events

https://www.e3lithium.ca/investors/upcoming-events/

CALGARY, ALBERTA, March 11, 2024 – E3 LITHIUM LTD. (TSXV: ETL) (FSE: OW3) (OTCQX: EEMMF), “E3 Lithium” or the “Company,” a leader in Canadian lithium, is pleased to announce recent additions to its team to help progress towards commercializing the Clearwater Project and share its upcoming presentation schedule.

Since the beginning of 2024, E3 Lithium has expanded its subsurface team, welcoming a new senior reservoir engineer and transitioning a former E3 Lithium lab employee, who spent the last two years working on Direct Lithium Extraction (DLE) technology and is a Geoscientist in Training, to the team to support resource development. The Company has also welcomed three new employees to corporate functions, including a new executive assistant and head of staff, a financial accountant and a marketing and digital communications specialist, all of whom will help steward the Company’s growth and achievement of upcoming catalysts.

E3 Lithium

8,169 followers

1d •

https://www.linkedin.com/feed/update/urn:li:activity:7168994662043541504/

An article shared last week outlines how Canada aims to reduce the development timeline for critical mineral mines from 12-15 years to approximately 5 years. This effort, focusing in part on minerals essential for manufacturing electric vehicles, highlights the government's commitment to electrifying the transportation sector, making Canada an attractive industry partner on the global stage.

This effort includes substantial investments in infrastructure and incentives for mining and mineral processing projects, enhancing Canada's ability to offer energy resources at affordable prices and strengthening its position in the lithium and broader critical mineral markets.

Read the full article here: https://lnkd.in/det226_q

E3 Lithium provides update on technology selections for first commercial Lithium

E3 LITHIUM LTD., a leader in Canadian lithium, has providde an update on the selection process for Direct Lithium Extraction (DLE) technology and the design of the downstream refining flowsheet for its first commercial facility.

In 2023, E3 Lithium committed to operating a field pilot plant to test DLE technologies at continuous scale to demonstrate the technical capability of various technologies to extract lithium efficiently from E3 Lithium’s brines. At the pilot, the Company operated its proprietary DLE technology and a third-party technology which produced successful results. In parallel, to ensure the Company had evaluated the available options to select the combination of processes that produce the best technical and economic results for its commercial design, E3 Lithium evaluated an additional three third-party DLE systems. The results of all the DLE technologies were similar to the results outlined from the pilot testing in terms of the recovery and lithium concentrate quality.

The most significant information received from all testing of DLE technologies that E3 Lithium completed was that each achieved technical success, which has significantly de-risked the commercial viability of the of the Company’s Leduc brines and Clearwater Project. The results also provided sufficient data to allow the Company to analyze each of the leading DLE options in combination with the downstream refining process, to select the optimal design for inclusion into E3 Lithium’s Prefeasibility Study (PFS). The Company’s primary goal is to make a decision that will enable immediate progression into the Feasibility Study and onto commercial construction and operations.

“We believe that it will commercialize” minute ~43:30 into the video.

Interesting choice of words.

E3 Lithium Investor Webinar February 2024

75ppm, good enough for IBAT, and returns in the black?

CALGARY, ALBERTA, January 25, 2024 – E3 LITHIUM LTD. (TSXV: ETL) (FSE: OW3) (OTCQX: EEMMF), “E3 Lithium” or the “Company”,

Alberta’s leading lithium developer and extraction technology innovator, today announced the discovery of higher lithium concentrations in the Nisku Aquifer (the Nisku) through a new six well sampling program conducted late in 2023.

E3 Lithium sampled brine in the Nisku from six well locations in its Clearwater Project Area that outlined lithium concentrations as high as 87 mg/L. These results are from the first Nisku samples in the Clearwater Project area, and are higher than the historic Nisku samples, which outlined lithium grades up to 75 mg/L.

Direct lithium extraction players to draw wave of M&A from battery supply chain

https://www.spglobal.com/marketintelligence/en/news-insights/latest-news-headlines/direct-lithium-extraction-players-to-draw-wave-of-m-a-from-battery-supply-chain-79694288

Emily Hersh

Developing lithium exploration projectsDeveloping lithium exploration projects

I learned so much asking Chris Doornbos P.Geo, ICD.D to explain Direct hashtag#Lithium Extraction hashtag#DLE to me in terms of "magical beads" and how to tweak a process to move massive amounts of fluids from point A to B.

I'm so happy for the E3 Lithium team for executing the pilot plant and can't wait to see what's next!

As far as lithium jrs go I've been following VLT.v for a while because of their proprietary method that can extract lithium from oilfield brines. The Canadian gov't is throwing support for E3 which is also developing DLE extraction tech, but VLT has a much smaller market cap rn. Some good info on them and their tech here if you're interested⬇️

https://www.reddit.com/r/Wallstreetbetsnew/comments/17ru854/revolutionizing_lithium_production_vlts_twostep/?utm_source=share&utm_medium=web2x&context=3

E3 Lithium Ltd EEMMF:OTCQX International

E3 Lithium Disclaims Recent Unsanctioned Promotional

Material

BusinessWire

3:49 PM ET

E3 LITHIUM LTD. (TSXV: ETL) (FSE: OW3) (OTCQX: EEMMF), "E3

Lithium", "the Company," was advised by the OTC Markets

Group Inc. ("OTC Markets") on October 25, 2023 of stock

promotion activity that the Company was previously unaware

of prior to the OTC Markets' notification. E3 Lithium

expressly disclaims, does not approve of, and has had no

involvement in the purported stock promotion.

At the request of the OTC Markets, the

Company will provide clarity regarding samples of

promotional material recently disseminated by

MrPennyStocks.com ("MPS") related to E3 Lithium:

At no time has E3 Lithium engaged MPS to

conduct any services for the Company; E3 Lithium has

not directly nor indirectly (i.e. through third-party

service providers) compensated MPS in any way, nor been

involved with any of the unsanctioned promotional materials.

Any insinuation to the contrary in MPS' material is false

and misleading; E3 Lithium has delivered a "Cease and

Desist" letter to MPS demanding that MPS immediately cease

and desist publication of any material about the Company and

that MPS remove any previously distributed material about E3

Lithium; E3 Lithium has comprehensive policies in

place in respect of its investor and public relations

activities and has previously disclosed all IR service

providers retained by the Company. The Issuer had no

knowledge of the promotional materials until notified by OTC

Markets Issuer Compliance Team, which monitors and enforces

OTC Markets Promotion Policies. As such, the Issuer had no

editorial control over the content; Readers should

not rely on any information contained in the material

distributed by MPS, as none of it is reliable nor reviewed

or approved by the Company.

Additional

information requested:

The Company has

observed no material change to its share price in relation

to the above-mentioned promotional activities.

To the Company's knowledge after inquiry,

no Director, officer, control person, controlling

shareholder (defined as a shareholder owning more than 10%

or more of the Issuer's securities) employee, contractor or

any third-party service provider has any relation to MPS,

nor were the relevant parties involved, directly or

indirectly, with the creation, distribution, or payment of

the MPS promotional materials. Over the past 12 months,

certain directors and officers sold shares totalling

224,500, as announced on October 4, 2023.

Over the past 12 months, the Company has

engaged with the following third-party service providers:

Native Ads Inc. (June 14, 2023), Independent Trading Group

(June 14, 2023), and Meadowbank Strategic Partners Inc.

(September 12, 2023).

The OTC Markets has

further requested that E3 Lithium state whether it has

issued any shares or convertible securities allowing

conversion to equity securities at prices constituting a

discount to current market rate at time of issuance. As

previously announced, the Company issued shares related to

two public offerings in the past 12 months. On June 8, 2023,

the Company closed a "bought deal" public offering for gross

proceeds of CAD$5,623,837 issuing 2,499,483 common shares of

the Company at a price of CAD$2.25 per Offered Share,

representing an 8% discount to the closing price on May 30,

2023. On September 26, 2023, the Company closed a "bought

deal" public offering for gross proceeds of CAD$23,025,300

issuing 6,486,000 common shares of the Company at a price of

CAD$3.55 per Offered Share, representing an 13% discount to

the closing price on September 15, 2023.

The Company encourages those interested in

the Company to rely solely on information included in press

releases issued and distributed by the Company through

approved news wire or disclosure and news services, combined

with its filings and disclosures made with SEDAR+.

ON BEHALF OF THE BOARD OF DIRECTORS

Chris Doornbos, President & CEO E3

Lithium Ltd.

E3- will be fine.

Clean coal technology that’s good for the environment and the economy

That's one hell of a cover there.....LMAO

Meanwhile, have you seen Albermarle and SQM and, and, and SGML, etc., etc. ?

Including E3 Metals

Sumpthin' must be happening to pricing in China or......

Or perhaps the market's just factoring in a Republican win and a return to burning coal.

.

White gold, welcome to the board. I can use some help posting info on E3 Thanks for posting and GLTA

ha-ha-ha yeah, there's been some stuff going on.

Like how they said - Black Magic

Have only listened to 1/2 so far (Chris really excels at yaking)

Volatile due to . . . . . am not quite sure - The Euro Expo which they're at ?

Anyhow, thanks

.

E3 Lithium (TSXV:ETMC) - Scaling Up Modular Direct Lithium Extraction in Canada. PFS results Q1 2024

Are you holding?

Pending Lithium Shortage Increases Commercialization Opportunities: E3 Lithium CEO

https://www.dailyoilbulletin.com/article/2023/10/5/pending-lithium-shortage-increases-commercializati/?ntoken=%2BDohnAl5LH1n0LG3adKTkGIXFuEqqKJojq5lHamUB7z%2FSp7ju7E2HWHR8mMxyVlxy8HK%2FbEZIgeZ9iuCTa8cJS6%2B%2FkhZh4pG76YnFdS%2FQq%2BUDamg5qnUC4erhgTGL%2Fti

E3 Lithium Investor Day 2023

The Q&A is at the end of the video last Chris says E3 WILL USE A THIRD PARTY DLE for the first plant.

But if you have the time watch it all.

E3 LITHIUM ADVANCES LITHIUM PRODUCTION TESTING AND PROVIDES FIELD PILOT PLANT COMMISSIONING UPDATE

CALGARY, ALBERTA, August 23, 2023

https://www.e3lithium.ca/newsroom/news-releases/e3-lithium-advances-lithium-production-testing-and-provides-field-pilot-plant-commissioning-update

E3 Lithium Ltd EEMMF:OTCQX International

E3 Lithium to Livestream Inaugural Investor Day on October 4

BusinessWire

3:05 AM ET

E3 LITHIUM LTD. (TSXV: ETL) (FSE: OW3) (OTCQX: EEMMF), "E3

Lithium" or the "Company", Alberta's leading lithium

developer and extraction technology innovator, invites

investors and interested parties to join the livestream of

its inaugural Investor Day on Wednesday, October 4. The

event will commence at 2 p.m. MT (4 p.m. ET).

During E3 Lithium's Investor Day,

management will provide fulsome updates on the business and

attendees will be invited to ask questions during the Q&A

session. Interested parties may also submit questions in

advance to investor@e3lithium.ca.

Details

Date: Wednesday, October 4, 2023 Time: 2

p.m. MT / 4 p.m. ET Please click here to join the live

webcast: Link Attendance is limited to 1,000 guests

Special offer for virtual attendees:

Limited edition E3 Lithium apparel will be offered to those

who join the livestream on October 4, while quantities last.

Virtual attendees will be required to submit their mailing

address to receive the item. More details will be provided

by the moderator when the livestream starts.

If attendees are not able to join the

event live on the day of the event, an archived webcast will

be made available on E3 Lithium's website.

ON BEHALF OF THE BOARD OF DIRECTORS

Chris Doornbos, President & CEO E3

Lithium Ltd.

E3 Lithium Pilot Plant Update

1,510 views Jun 15, 2023

June 14 2023

E3 Pilot Montage - 2023

My bid I put in on 9-12 is at $2.50US came down to $2.56 I think I can wait a couple more days, on my radar..

E3 Lithium Announces $20.0 Million Bought Deal Public

Offering

BusinessWire

7:00 AM ET

E3 LITHIUM LTD. (TSXV: ETL) (FSE: OW3) (OTCQX: EEMMF), "E3

Lithium" or the "Company", Alberta's leading lithium

developer and extraction technology innovator, today

announced that it has entered into an agreement with Eight

Capital to act as lead underwriter and sole bookrunner on

behalf of a syndicate of underwriters (collectively, the

"Underwriters"), pursuant to which the Underwriters have

agreed to purchase for resale 5,640,000 common shares of the

Company (each, an "Offered Share") at a price of C$3.55 per

Offered Share (the "Offering Price") on a "bought deal"

basis for gross proceeds of C$20,022,000 (the "Base

Offering").

The Company has granted to

the Underwriters an option (the "Over-Allotment Option", and

together with the Base Offering, the "Offering"),

exercisable for a period of 30 days after and including the

closing date of the Offering, to purchase for resale up to

an additional 15% of Offered Shares at the Offering Price to

cover over-allotments, if any, and for market stabilization

purposes.

The net proceeds from the

Offering will be used towards the advancement of the

Clearwater Project and corporate development activities.

The Offered Shares will be sold by way of

a prospectus supplement to be filed in all of the provinces

of Canada, other than Quebec, to supplement the Company's

short form base shelf prospectus dated April 18, 2022. The

Offered Shares may also be sold in the United States on a

private placement basis pursuant to one or more exemptions

from the registration requirements of the United States

Securities Act of 1933, as amended (the "U.S. Securities

Act"), and in such other jurisdictions outside of Canada and

the United States, in each case in accordance with all

applicable laws provided that no prospectus, registration

statement or similar document is required to be filed in

such jurisdiction.

The Offering is

scheduled to close on or about September 26, 2023 and is

subject to certain conditions including, but not limited to,

the receipt of all necessary approvals, including the

approval of the TSX Venture Exchange.

The

Offered Shares have not been and will not be registered

under the U.S. Securities Act and may not be offered or sold

in the United States absent registration or an applicable

exemption from the registration requirements under the U.S.

Securities Act and applicable states securities laws. This

news release shall not constitute an offer to sell or the

solicitation of an offer to buy nor shall there be any sale

of any securities in any jurisdiction in which such offer,

solicitation or sale would be unlawful.

ON BEHALF OF THE BOARD OF DIRECTORS

Chris Doornbos, President & CEO E3

Lithium Ltd.

About E3 Lithium

E3 Lithium is a development company with a

total of 16.0 million tonnes of lithium carbonate equivalent

(LCE) Measured and Indicated and 0.9 million tonnes LCE

Inferred mineral resources(1) in Alberta. As outlined in

E3's Preliminary Economic Assessment, the Clearwater Lithium

Project has an NPV8% of USD 1.1 Billion with a 32% IRR

pre-tax and USD 820 Million with a 27% IRR after-tax(1). E3

Lithium's goal is to produce high purity, battery grade

lithium products to power the growing electrical revolution.

With a significant lithium resource and innovative

technology solutions, E3 Lithium has the potential to

deliver lithium to market from one of the best jurisdictions

in the world.

1: The Preliminary Economic

Assessment (PEA) for the Clearwater Lithium Project NI

43-101 technical report is amended Sept 17, 2021. Gordon

MacMillan, P.Geol, QP, Fluid Domains Inc. and Grahame Binks,

MAusIMM, QP (Metallurgy), formerly of Sedgman Canada Limited

(Report Date: June 15, 2018, Effective Date: June 4, 2018

Amended Date: September 17, 2021). The mineral resource NI

43-101 Technical Report for the North Rocky Property,

effective October 27, 2017, identified 0.9Mt LCE (inferred).

The mineral resource NI 43-101 Technical Report for the

Bashaw District Project, effective March 21, 2023,

identified 16.0Mt LCE (measured & indicated). All reports

are available on the E3 Lithium's website

(e3lithium.ca/technical-reports) and SEDAR+

(www.sedarplus.ca).

Forward-Looking and

Cautionary Statements

This news release

includes certain forward-looking statements as well as

management's objectives, strategies, beliefs and intentions.

Forward looking statements are frequently identified by such

words as "may", "will", "plan", "expect", "anticipate",

"estimate", "intend" and similar words referring to future

events and results. In particular, this news release

contains forward-looking information pertaining to the

Offering and the proposed use of proceeds therefrom.

Forward-looking statements are based on the current opinions

and expectations of management. All forward-looking

information is inherently uncertain and subject to a variety

of assumptions, risks and uncertainties, including the

speculative nature of mineral exploration and development,

fluctuating commodity prices, the effectiveness and

feasibility of emerging lithium extraction technologies

which have not yet been tested or proven on a commercial

scale or on the Company's brine, competitive risks and the

availability of financing, as described in more detail in

our recent securities filings available at www.sedarplus.ca.

Factors that could cause actual results to differ materially

from such forward-looking information include, but are not

limited to, changes in the state of equity and debt markets,

delays in obtaining required regulatory approvals, failure

to satisfy closing conditions in respect of the Offering and

other risks and uncertainties involved in the mineral

exploration and development industry. Forward-looking

information in this news release is based on the opinions

and assumptions of management considered reasonable as of

the date hereof, including, but not limited to, the

assumption that all conditions precedent to the completion

of the Offering (including the receipt of all requisite

regulatory approvals) will be satisfied in a timely manner;

and general business and economic conditions will not change

in a materially adverse manner. Actual events or results may

differ materially from those projected in the

forward-looking statements and we caution against placing

undue reliance thereon. We assume no obligation to revise or

update these forward-looking statements except as required

by applicable law.

Neither the TSX

Venture Exchange nor its Regulation Services Provider (as

that term is defined in the policies of the TSX Venture

Exchange) accepts responsibility for the adequacy or

accuracy of this release.

View source

version on businesswire.com:

https://www.businesswire.com/news/home/20230917767085/en/

ha-ha ! LoL....Sweet

along with two third party

technologies.......

E3 LITHIUM LTD. (TSXV: ETL) (FSE: OW3) (OTCQX: EEMMF), "E3

Lithium" or "the Company," Alberta's leading lithium

developer and extraction technology innovator, today

provides a preliminary update on the Direct Lithium

Extraction (DLE) technology results at its field pilot

plant.

Via its DLE field pilot plant, E3

Lithium is conducting a series of three predefined tests to

review various operating conditions to understand

anticipated performance in a commercial environment. Once

all three tests are complete, E3 Lithium will select the

operating conditions that produced the best results to run

for a longer period.

The success of the

longer operating period will confirm the results of the

initial testing and will enable the commercial design of

this system for both the Pre-Feasibility Study (PFS) and

subsequent engineering designs. In addition, the lithium

concentrate produced by the longer operating period will be

used for the development of the lithium production system

for the PFS and subsequent engineering designs.

The internal analysis and results of the

first of the three tests are outlined below:

Initial lithium recovery: > 94%

Purity of concentrate: > 80% Average lithium grade

in concentrate: 884 mg/L

"These results

demonstrate an initial positive indication that the pilot is

operating as expected," said Chris Doornbos, President and

CEO of E3 Lithium. "The E3 Lithium team is working hard to

progress the pilot and is continuing to operate the pilot

safely. We appreciate the outpouring of community support

since operations began and are very excited to be able to

outline these preliminary results."

Throughout pilot operations, E3 Lithium

will be testing its technology along with two third party

technologies. A full suite of results from the predefined

testing currently underway will be available at the start of

the longer operating period. At that point, E3 will provide

the results against the KPIs outlined in June. The results

presented today should not be considered a full

representation of performance of the pilot.

International Battery Metals Ltd.: Woodbury Carper Lithium Resource Project Exploration Commences

Vancouver, British Columbia--(Newsfile Corp. - October 5, 2017) - International Battery Metals Ltd. (CSE: IBAT) ("IBAT" or the "Company") The Company is pleased to announce that it has commenced the testing and evaluation of the optioned Woodbury Carper Lithium Resource Project being 37,500 acres of oil and gas leases located in Cumberland and Jasper Counties Illinois. Through this initial program, the Company will advance its objectives of quantifying the lithium content of the brine on the optioned properties and exploring the application of different extraction methodologies.

As announced in the Company's July 24, 2017 news release, lithium on these properties were discovered as a result of drilling three exploratory wells in the search for oil and gas from the New Albany Shale and Carper Sandstone. Readers are referred to that news release for further details.

These initiatives reflect the Company's strategic move to focus on lithium in oil and gas brines in North America where it can utilize the latest lithium specific expertise and technologies as described in the Company's news release of October 2, 2017 in the best interests of the Company.

ON BEHALF OF THE BOARD

"Logan Anderson"

Logan Anderson, CEO and Director

https://www.newsfilecorp.com/release/29501/International-Battery-Metals-Ltd.Woodbury-Carper-Lithium-Resource-Project-Exploration-Commences

Lithium tech developers eye ways to boost water recycling

By Ernest Scheyder

September 13

Just for you Nowwhat2 There is no way someone would spend $450-million for EnergySource's DLE for oil well brines. And E# and IBATF can get GRANTS for new tech. My guess that is why IBATF is doing all the testing to get GRANTS.

E3 Lithium, which is backed by Exxon’s Imperial Oil, began testing three DLE technologies last month in Alberta and aims to install water recycling facilities as it goes commercial, said CEO Chris Doornbos.

“You end up having a small water treatment facility with your processing facility so they can reuse that water over and over and over again,” said Doornbos.

Oh wow.......THIS has gotta factor in too there (they're gettin' divorced and they've lost some of thier secret sauce)

https://www.reuters.com/world/china/markets/commodities/sigma-lithium-eyeing-buyout-sues-ex-ceo-daughter-in-law-over-trade-secrets-2023-08-22/

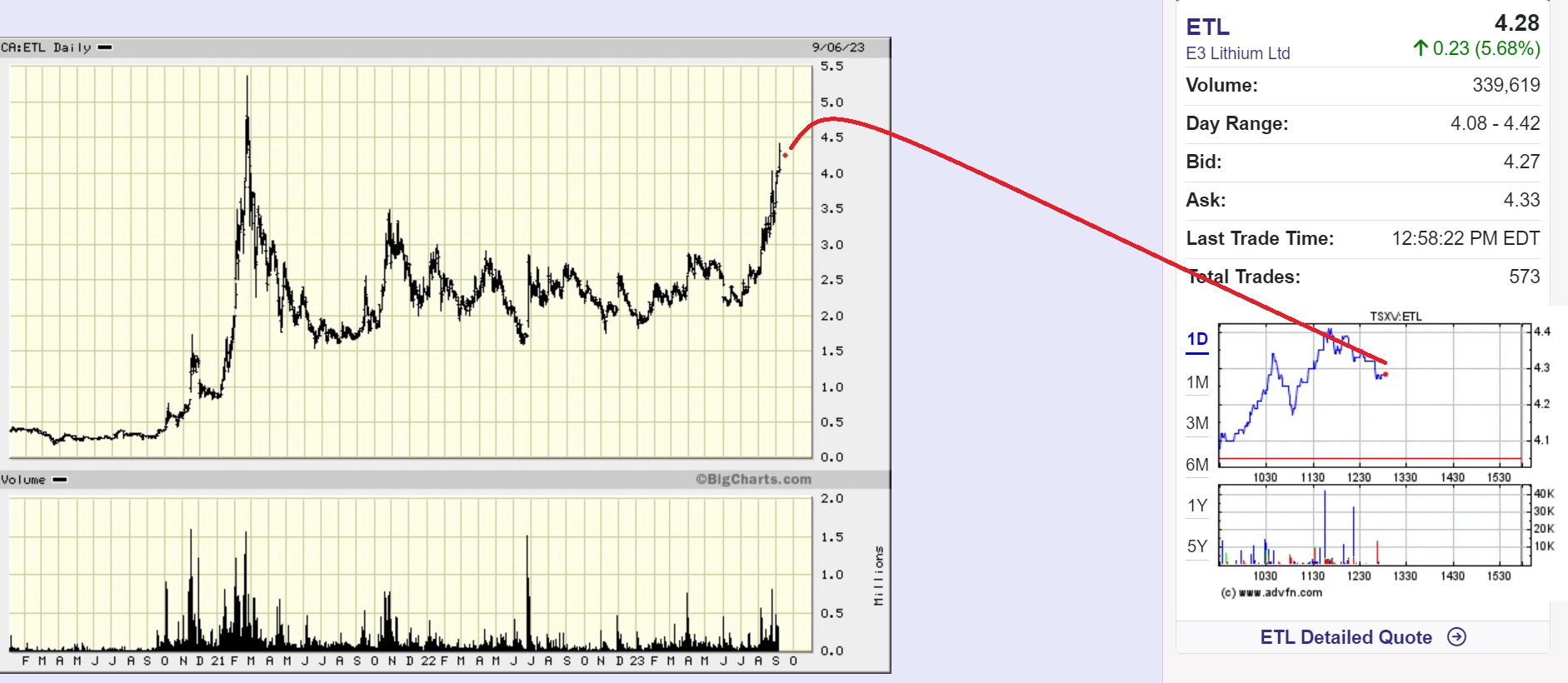

Out at 4.30 = Damn

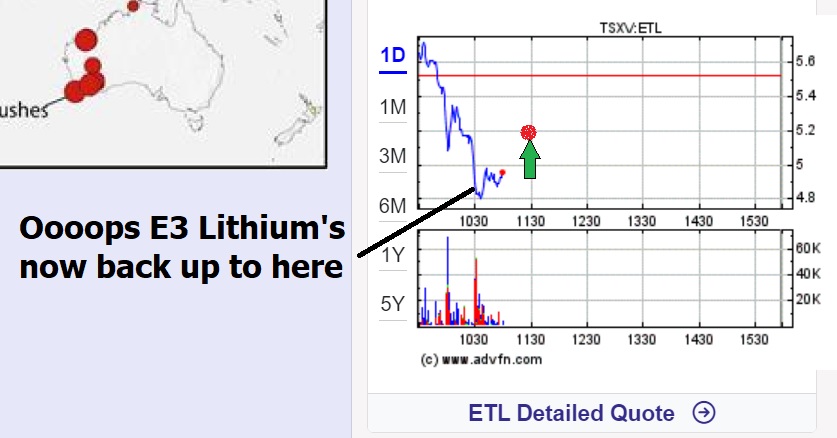

MEANWHILE ; Remember ?

NOW look at it.........There it is...........MKT CAP = 5 B

Compared to

I dunno......I'm not a expert.............That's why I need your help.

https://www.chemistryworld.com/news/lithium-discovery-in-us-volcano-could-be-biggest-deposit-ever-found/4018032.article

Always

Note :

Should'a jumped into WEED stocks too

.

.

Still climbing, $10?

That was stupid.......I knew this could happen......

Just couldn't believe that it could : Not in this here lith enviro and on such fluffy pilot promotion

Oh well.......I reckon one should actually be shorting it now then.....

Thing is so OBVIOUSLY a total chart-play

What I DID like about Chris' presentation here was his mention that they're targeting up 150,000 t per annum

https://twitter.com/i/broadcasts/1ynJOaMNPzyKR

https://twitter.com/i/broadcasts/1ynJOaMNPzyKR

Our CEO, @ChrisJdoornbos, will be speaking on a panel at @Reuters #IndustryTransition2023 in Pittsburgh, highlighting the transformative impact of Direct Lithium Extraction (DLE) technologies on the green energy transition.

— E3 Lithium (@e3lithium) September 6, 2023

Learn more about this event and secure your spot by… pic.twitter.com/kIvWWP4DVo

Handy site indeed

https://www.stocktitan.net/news/NSRCF/next-source-announces-mo-u-for-strategic-collaboration-with-south-gc16yy97l9tt.html

Am in up at 2.81 there - LoL - Am down 43 percent !........

As you know - The Battery METALS Sector has NOT been much FUN !

.

And it's 6.5 million - Not my 3 million

Thanks - Nice find - Looks like a handy site for pulling up news

https://www.stocktitan.net/news/XOM/imperial-and-e3-lithium-form-strategic-agreement-on-lithium-pilot-r0pnt6gpk2e4.html

Oh was it Imperial - Yeah - So sorry I get (got) the two mixed up

Both pretty Big Oil tho - Albeit a laughable (I believe) 3 million dollar IMPERIAL investment

Thanks for the clarification !

I never knew Exxon-Mobile was involved in E3. What are they doing? I found this pr, I am not finding exxon.

Imperial and E3 Lithium form strategic agreement on lithium pilot project in Alberta

June 23, 2022 - 7:55 am

Advances E3 Lithium’s Clearwater Project with Imperial funding contribution

Pilot project progresses commercialization of battery-grade lithium from historic Leduc field for electric vehicles and energy storage

Imperial to provide technical and development support

CALGARY, AlbertaImperial Oil Limited (TSE: IMO, NYSE American: IMO) and E3 Lithium (TSXV: ETMC, OTCQX: EEMMF) announced today a collaboration to advance a lithium-extraction pilot in Alberta, exploring the redevelopment of an historic oil field into a potential new leading source of lithium for Canada’s growing critical minerals industry.

https://www.stocktitan.net/news/XOM/imperial-and-e3-lithium-form-strategic-agreement-on-lithium-pilot-r0pnt6gpk2e4.html

he-he okay I'm out at the 4.30......That was just too freaking nutso.

IBAT (I THINK) is so much further along than them (as far as extraction goes at least)

'Course IBAT doesn't have any LAND leases though.....

Mind you - Doen't E3 have a half-decent extraction partner tho ?

What is/was their name again ?

LoL - Out at 4.30 (70 %) - Just nuts 'cuz it still LOOKS like it COULD keep tryin' to shoot for its' ATH

.

Sayona people on stocktwist sold Sayona and went to E3. For them it was the share float. I am not going to argue with them. They think they are safe from dilution.

I was going to argue with him that dilution is coming. But, I have better things to do.

https://stocktwits.com/jdbucha/message/543479447

Just ridiculous what's going on with this E3

And all just because they

(A) Hired a new public relations firm ?

and

(B) FINALLY Started constructing a pilot plant ?

(C) Recieved (paltry) 3 million dollar investments from both Exon ? and Govt. ?

Almost sold this 2.50 entry at 3.50 but (somehow) have managed to hold on.....LoL

Am quite certain that i should be dumping it right now as I type......Last 4,35.....Been as high as 4.42

UNLESS it actually goes up and repokes the 5.40 ! ??????

Answer = Trailing Stops - Which I STILL haven't yet freaking "figured out" up here....

We've got these (stupid) things called "Stop Loss Limit Orders" instead of just some kind of (simple) Trailing Stop Loss

.

.

|

Followers

|

7

|

Posters

|

|

|

Posts (Today)

|

0

|

Posts (Total)

|

459

|

|

Created

|

09/18/19

|

Type

|

Free

|

| Moderators TradingCharts | |||

| Volume | |

| Day Range: | |

| Bid Price | |

| Ask Price | |

| Last Trade Time: |