Monday, February 27, 2012 2:50:18 PM

Recent Progress:

1-20-12: Plastic2Oil Viability Re CONFIRMED

1-9-12: $2.8M Financing Secured

12-23-11: Transport Fuel (Regular, Premium, Diesel) supply agreement with XTR Energy

12-21-11: Long Term Fuel Supply Agreement with Indigo Energy

1. Shareholder Equity: $5M

2. P20 Revenues

Q2: $81K

Q3: $141K Revenue Gain: +73%

3. Net Loss:

Q2: $4.5M

Q3: $3.3M: Losses Down 27%

4. Cash On Hand: $2.4M

5. For the three and nine month period ending September 30, 2011, P2O gross margin performance was approximately 83.6% and 77.2% respectively (2010: N/A).

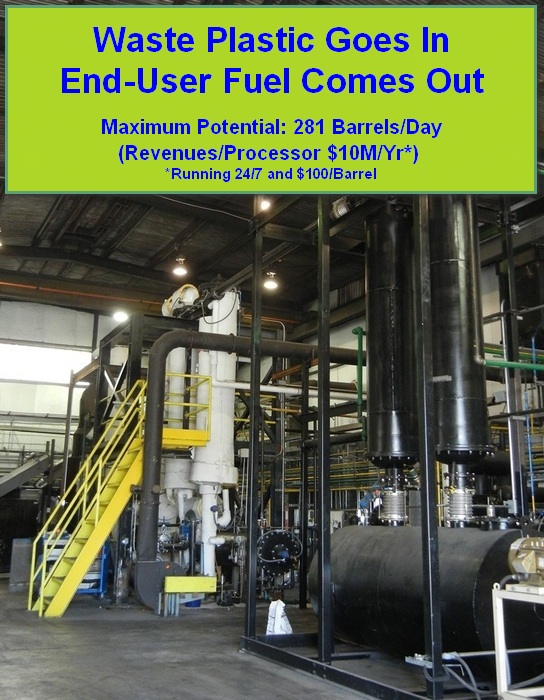

6. JBII is an alternative oil and gas company that converts waste plastic into fuel; primarily diesel, #2 fuel oil, and #6 fuel oil.

7. In March 2011 the Company completed the acquisition of the facility in Niagara Falls, New York where its 20 metric tonne (“MT”) P2O processor is located. On October 4, 2011, the Company paid out the outstanding mortgage for the facility.

8. In addition, on October 27, 2011 the Company was permitted by the city of Niagara Falls to erect a 7200 square foot building on the Niagara Falls, NY property. The foundation has been poured and a prefabricated building has been purchased. The Company anticipates construction to be complete at the end of Q4 2011. This building will house the Company’s fabrication operations.

9. The Company plans to move its fabrication unit from the existing facility to the new building shortly after construction is complete. The construction of a secondary location for fabrication was imperative as it will allow the Company to continue manufacturing processors without interrupting operations and fuel production going forward.

10. The Company focused resources in Q3 on finalizing and completing the construction of the premelt system, ordering components for and fabricating processors #2 and #3, and initializing site preparation for the rollout of processors at the first RockTenn site.

11. The Company expects to finalize fuel supply agreements as soon as anticipated fuel demand from prospective customers can reasonably be met.

12. Management’s highest priority continues to be bringing processor #2 and #3 online so the Company can become cash flow positive.

13. Patent: The Company has filed confidential patent applications with the USPTO to protect its intellectual property.

14. The Company continues to strategically build the foundation for its Plastic2Oil business that it expects will create long-term value and a profitable business.

15. The completion of the premelt was critical to the efficiency of commercial operations and expansion to third party locations.

16. The Company continues to be successful in securing free sources of feedstock supply for the processing plant, both independently and through its recycling facility that accepts, separates and processes paper, plastics and other materials.

17. The Company has also constructed tank containment in New York, which added 49,000 gallons of on-site fuel storage in addition to the 250,000 gallon fuel blending site in Canada. This extra storage will support growing operations and fuel transport flexibility in Niagara Falls, NY.

18. On July 29, 2011, the Company entered into a Revenue Sharing Agreement with RockTenn to convert mill and MRF waste plastic into fuel using JBI’s Plastic2Oil technology. Prior to executing the Revenue Sharing Agreement and Addendum for the first site, JBI visited numerous RockTenn sites to plan installation priorities. The Company has been meeting regularly with RockTenn representatives in order to prepare for the first installation of processors on their site. The Company met with environmental authorities in the state where the first processors are being placed. Due to the ultra-low emissions from the Company’s P2O processor, the Company sought a permit exemption. During September 2011, the Company proposed and submitted an application for exemption and met with several of the State’s environmental engineers. The Company also presented before the environmental committee composed of citizens, environmental engineers, and permit engineers. The Company has retained contractors to install services on site at the first RockTenn location. The site has an existing pad and small building already in place, which will be used for P2O operations. In preparation for the construction of the first processors, the Company has hired and trained new operators and fabricators in Niagara for future relocation to this initial RockTenn site.

19. The Company expects to have the kilns from fabrication shops for processor #2 and #3 in Niagara Falls, NY by the time the final stack test is conducted in December 2011. Catalyst towers, heavy fuel, naptha and natural gas towers for both of these new machines have already been constructed.

20. P2O Processor Enhancements:

Q1: The Company’s CEO designed further enhancements to the P2O processor in early 2011, including two columns supporting 4 catalyst trays. In addition, he added significant technology to guarantee fuel quality, along with installing an inline fuel additive injection system on both heavy and light fuel condensing systems. He has also engineered a hot-tap residue removal process. Quality control includes two columns for control and specificity of fuel fractions, a cyclone (particulate removal in vapor), fuel filters (particulate removal in liquid), and a centrifuge (additional redundant particulate trap), as well as column enhancements to guarantee particulate free fuel. Fuel additives are injected inline while fuel is being produced to increase their effectiveness. The new residue removal system works while the processor is running, so the reactor does not have to be cooled down or stopped to remove residue.

Q2: During the second quarter of 2011, the Company built a fully equipped fuel testing laboratory at the Niagara Falls, NY site to facilitate instant certification of fuel products. The P2O processor is capable of producing #6 fuel, #2 fuel, diesel, and light naphtha. The Plastic2Oil processor has been tuned to reduce naphtha production to less than 2% because the market price for naphtha is significantly less compared to #2 or #6 fuel and therefore the Company does not intend to make Naptha contracts a priority. The Company’s management has invested much time, testing, and production efforts towards large companies to execute significant contracts such as RockTenn. During the first quarter of 2011 the processor was primarily used to test feedstock from large sources of free waste plastic in order to pass "Cradle to Grave" audits from feedstock to end user fuel. During the second quarter of 2011 the Company designed and engineered a premelt loader for the Plastic2Oil processor to eliminate handling, shredding, and bagging of waste plastic. During the modularization of the processor, the CEO was able to eliminate the off gas compression system in favor of a simplified low-cost off gas handling rack (4’ x 4’ x 4’) for better control and at 1/5 of the cost. The cost savings through modularization has been used to offset the cost of the premelt loader.

Q3: The Company successfully designed, engineered and fabricated a plastic premelt system. The premelt system is now capable of accepting mixed, un-shredded plastics in addition to plastics that are comingled with various metals. The premelt system operates from the waste heat of the original P2O reactor system and has the ability to separate the comingled metals from the plastic. This capability became especially critical for processing RockTenn material such as raggertail, as well as other large bales of compacted plastic. The raggertail was demonstrated to be successfully processed during a visit by RockTenn representatives and will significantly increase process efficiency at RockTenn sites, as well as alleviating a great deal of sorting efforts from many of the Company’s current and future plastic feedstock suppliers. In addition to the completion of the premelt system, the Company further enhanced the New York processor by installing Low Nox (Nitrogen Oxide) burners. This addition will further reduce emissions and was important when seeking permit exemptions in other States. This improvement enabled the Company to seek an air permit exemption in another State, eliminating many months of extra work and cost.

The Company became able to dye its own fuel thereby eliminating the need to blend or have 3rd parties perform this service. These changes, in combination with a declining number of test runs required for base-lining emission and other fuel standards tests are expected to result in continuous performance and enhanced throughput.

21. B2B Agreements:

On June 10, 2011, JBI, Inc. entered into a Supply and Service Agreement with Coco Asphalt Engineering, a division of Coco Paving whereby the Company has agreed to supply Coco on a weekly per demand basis with petroleum distillate at a cost of $109.80 per barrel. The Company continues to ship tankers of petroleum distillate to Coco Paving in third quarter at $109.80 per barrel. Coco Paving has stated it is pleased with our Plastic2Oil fuel.

On July 29, 2011, the Company entered into a Revenue Sharing Agreement with Rock-Tenn Company (RockTenn) to convert mill by-product waste into fuel using JBI's Plastic2Oil technology. Under the agreement, JBI, Inc. has an exclusive ten-year license with a renewal option to build and operate P2O processors at RockTenn facilities to process RockTenn's waste plastic at paper mills and Material Recovery Facilities and to mine and process plastic from RockTenn's plastic-filled monofill sites.

22. Processor Production:

The Company has contracted two fabrication shops to manufacture the reactors and towers in racks. The Company has also ordered a prefab building for its P2O factory property for fabricating proprietary and trade secret components for the racks. The racks have been standardized to limit the number of parts and vendors in the supply chain that the Company must depend upon. Transient delays in Q3 were related to supplier companies being bought out, moving, or ceasing operations. The Plastic2Oil processor system is now 10’ wide by 120’ long. On November 15, 2011, the Company was granted Honeywell Maxon OEM (Original Equipment Manufacturer) status. This certification will allow the Company to order and receive key processor parts on a priority basis. It is anticipated that this will save the Company significant time and money moving forward.

23. Free Plastic

The Company receives free waste plastic for our Plastic2Oil processor(s) from Chrysler, General Motors, major food packagers, dairy companies, agricultural plastics, and many other sources. The company is recycling thousands of gas tanks, bales of plastic film and many other free plastics that are usually sent to landfill. The Company does not pay for any plastic. None of the plastic that the Company has received to date at the P2O factory has required sorting. The Company continues to receive large supplies of plastic feedstock at both its Niagara Falls, NY and Thorold, Ontario facilities, and retains a significant backlog of feedstock. The Company anticipates continuous processing of this supply upon completion of the second stack test and assembly of processors #2 and #3.

24. China Regulatory Implications:

In August 2011, China implemented regulations that greatly limit waste plastic importing. The regulation strictly limits waste import licenses and the waste plastic product must be used as a raw material in a new product. This regulation was implemented to curb pollution caused by burning waste plastics. As of November 2011, the regulation was tested and enforced in Guangzhou province and it successfully resulted in reducing waste plastic imports by 80%. China warns that strict enforcement of the new regulations will soon be extended to the entire country. The Company expects this regulation to be very beneficial in securing long term feedstock supply.

25. Tape Recovery Business:

In 2009, the Company purchased the Data business from John Bordynuik, Inc., thereby providing the Company with the ability to operate what was once John Bordynuik, Inc.’s data restoration and recovery business, a business originally developed by John Bordynuik in 2006.

The Data Business is not as financially intensive as the other businesses of JBI, but is time consuming with regards to the allocation of the time of John Bordynuik, the President and CEO. However, the Company continues to maintain operations of this business segment and has received several thousand tapes for reading and data preservation. The Company expects to be generating revenue from the Data Business segment in future periods.

26. PakIt:

Despite these measures actual and anticipated revenue and profitability performance at Pak-it failed to meet expectations and the Company determined that a selective divesture of Pak-it’s assets was warranted in order to focus on its P2O segment. During the second quarter, sale criteria in respect of certain assets of Pak-it was developed and active marketing commenced to sell these assets.

z

VHAI - Vocodia Partners with Leading Political Super PACs to Revolutionize Fundraising Efforts • VHAI • Sep 19, 2024 11:48 AM

Dear Cashmere Group Holding Co. AKA Swifty Global Signs Binding Letter of Intent to be Acquired by Signing Day Sports • DRCR • Sep 19, 2024 10:26 AM

HealthLynked Launches Virtual Urgent Care Through Partnership with Lyric Health. • HLYK • Sep 19, 2024 8:00 AM

Element79 Gold Corp. Appoints Kevin Arias as Advisor to the Board of Directors, Strengthening Strategic Leadership • ELMGF • Sep 18, 2024 10:29 AM

Mawson Finland Limited Further Expands the Known Mineralized Zones at Rajapalot: Palokas step-out drills 7 metres @ 9.1 g/t gold & 706 ppm cobalt • MFL • Sep 17, 2024 9:02 AM

PickleJar Announces Integration With OptCulture to Deliver Holistic Fan Experiences at Venue Point of Sale • PKLE • Sep 17, 2024 8:00 AM