| Followers | 9 |

| Posts | 1597 |

| Boards Moderated | 1 |

| Alias Born | 01/27/2014 |

Monday, July 03, 2017 11:33:24 AM

The Qualification Quandary

At tctmagazine.com - The Qualification Quandary - 3 July 2017

Selected sections:

The Claim

“Norsk Titanium to Deliver the World’s First FAA-Approved, 3D-Printed, Structural Titanium Components to Boeing,” said the headline on top of April 10, 2017, press release from Norsk. I knew it was coming, I had spoken to CEO, Warren Boley two months previously with the aim of covering the story in our sister publication across the pond. Unfortunately, I couldn’t confirm nor deny it to be true before my deadline, and we didn't run with it.

Eventually, Boeing confirmed, and an FAA spokesperson got back to me with the following statement, confirming Norsk’s statement to be true, albeit in a semantically odd way: “It is accurate that Norsk Titanium is the Boeing-approved supplier for 787 galley fittings, but they are not “FAA-approved” as such. We do not approve any supplier or certify their designs. They are indirectly approved as a vendor through Boeing, and Boeing is responsible for showing that the parts comply with applicable regulations as part of the 787 type design.”

_______________________________________________________________

The Steps

What I hadn’t grasped was that FAA does not approve the process of making a part, it approves the aircraft, and it is up to the OEM to endorse the supplier of parts. Scott Sevcik, Head of Aerospace, Defense & Automotive at Stratasys explained in more detail:

“You either present an aircraft to the FAA, or a modification to an aircraft. There are standards, the regulations to which you must certify but every one of those projects is unique, you work with the airworthiness authority to show how you are going to comply with the regulations. What they ultimately certify is that vehicle or modification, they are not certifying a vendor or process, they will leverage qualifications that have been performed as part of a certification plan for a vehicle.”

It’s this very certification process that makes it tough for additive manufacturing (AM) to get to the point of confidence for it to be considered a norm in aerospace manufacturing. In August 2015 Terry Khaled, PhD, Chief S/T Advisor, Metallurgy at the FAA produced a presentation on AM for the FAA, which said:

“My understanding is that FAA seldom approves materials and processes as standalone entities, materials and processes approvals are implied when a particular design has been certificated regardless of whether this design is a component, an engine or an aircraft. Therefore, why is FAA attempting to regulate AM as a standalone entity?”

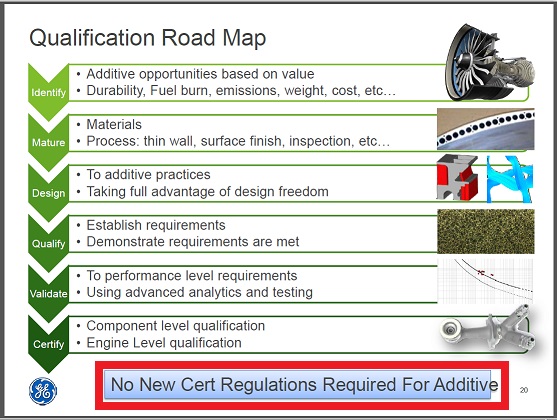

This is consistent with other documentation presented by Greg Morris (GE)

At fda.gov - GE Aviation – Additive Road to Production

At fda.gov - Capital Reporting Company Additive Manufacturing of Medical Devices Public Workshop - 10/8/2014

Morris begins on page 86 and continues for quite a while:

So if you've noticed, all of these concerns are features of a device, not a specific technology necessarily. And, again, if you are printing something fully dense, a lot of these concerns are minimized. So again this is going to be a function of your technology and your device in terms of what we're worried about.

So I have a series of subject matter experts who are going to talk more about this.

The first one is going to be Greg Morris of GE Aviation, and he is going to be discussing their process of taking the additive manufacturing process to full production.

Greg?

(Applause.)

MR. MORRIS: All right. Thank you, Matthew, and good morning, everyone. It's good to be here. Let's see.

All right. So, no, I didn't take a wrong turn and miss the FAA and come to the FDA; and, yes, I am with GE Aviation.

So prior to GE Aviation I was with a company called Morris Technologies. We also got involved in the medical business. GE Aviation acquired our company, and we really became aviation-centric.

So, look, the reason I'm here I think in part is to give a perspective of a different industry, and perhaps some of the similarities and maybe more so the similarities and some of the differences between what you do in the medical world and what our experience has been in the aviation world, and specifically around additive metals is where I am going to concentrate a lot of my effort.

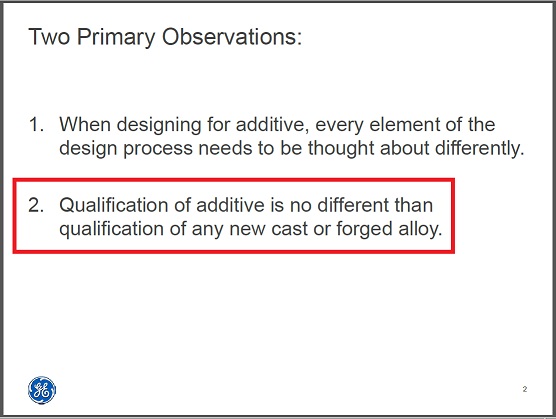

So the first two things, I think it's fair to say in two primary observations that we would make at GE is that, number one, when you're designing for additive, every element of the design process needs to be thought about differently. So we've kind of touched on that. We've heard that from a few presentations already, but this is really an important point. You can't generally take, at least in our world, we have found you cannot generally take a design that was meant for castings or fabrications or machining and think you are going to just be successfully producing the same part with an additive technology.

So we've learned that lesson very well on one of the parts I'll show you here today.

The other one is that from our perspective at least -- and this would of course be through the FAA -- that the qualification of additive is really no different than qualification of any new cast or forged alloy. That's a pretty significant statement from our perspective because what we're trying to say is we don't believe that the process itself should be certified, we believe still that the components we produce, the engines, should be certified, and that's a very important point for a lot of reasons. There are cost reasons and there are regulatory reasons, but at least in our world, that's how we view it, and we think and we hope that the FAA views it in a very similar way.

So let me just go through a little bit of our pedigree of where we've been with additive and some of the things that we use...

Ernesto Rios Director of Manufacturing Operations at Renovis Surgical Technologies discusses electron beam melting beginning on page 45.

At tctmagazine.com - The Qualification Quandary - 3 July 2017

Selected sections:

The Claim

“Norsk Titanium to Deliver the World’s First FAA-Approved, 3D-Printed, Structural Titanium Components to Boeing,” said the headline on top of April 10, 2017, press release from Norsk. I knew it was coming, I had spoken to CEO, Warren Boley two months previously with the aim of covering the story in our sister publication across the pond. Unfortunately, I couldn’t confirm nor deny it to be true before my deadline, and we didn't run with it.

Eventually, Boeing confirmed, and an FAA spokesperson got back to me with the following statement, confirming Norsk’s statement to be true, albeit in a semantically odd way: “It is accurate that Norsk Titanium is the Boeing-approved supplier for 787 galley fittings, but they are not “FAA-approved” as such. We do not approve any supplier or certify their designs. They are indirectly approved as a vendor through Boeing, and Boeing is responsible for showing that the parts comply with applicable regulations as part of the 787 type design.”

_______________________________________________________________

The Steps

What I hadn’t grasped was that FAA does not approve the process of making a part, it approves the aircraft, and it is up to the OEM to endorse the supplier of parts. Scott Sevcik, Head of Aerospace, Defense & Automotive at Stratasys explained in more detail:

“You either present an aircraft to the FAA, or a modification to an aircraft. There are standards, the regulations to which you must certify but every one of those projects is unique, you work with the airworthiness authority to show how you are going to comply with the regulations. What they ultimately certify is that vehicle or modification, they are not certifying a vendor or process, they will leverage qualifications that have been performed as part of a certification plan for a vehicle.”

It’s this very certification process that makes it tough for additive manufacturing (AM) to get to the point of confidence for it to be considered a norm in aerospace manufacturing. In August 2015 Terry Khaled, PhD, Chief S/T Advisor, Metallurgy at the FAA produced a presentation on AM for the FAA, which said:

“My understanding is that FAA seldom approves materials and processes as standalone entities, materials and processes approvals are implied when a particular design has been certificated regardless of whether this design is a component, an engine or an aircraft. Therefore, why is FAA attempting to regulate AM as a standalone entity?”

This is consistent with other documentation presented by Greg Morris (GE)

At fda.gov - GE Aviation – Additive Road to Production

At fda.gov - Capital Reporting Company Additive Manufacturing of Medical Devices Public Workshop - 10/8/2014

Morris begins on page 86 and continues for quite a while:

So if you've noticed, all of these concerns are features of a device, not a specific technology necessarily. And, again, if you are printing something fully dense, a lot of these concerns are minimized. So again this is going to be a function of your technology and your device in terms of what we're worried about.

So I have a series of subject matter experts who are going to talk more about this.

The first one is going to be Greg Morris of GE Aviation, and he is going to be discussing their process of taking the additive manufacturing process to full production.

Greg?

(Applause.)

MR. MORRIS: All right. Thank you, Matthew, and good morning, everyone. It's good to be here. Let's see.

All right. So, no, I didn't take a wrong turn and miss the FAA and come to the FDA; and, yes, I am with GE Aviation.

So prior to GE Aviation I was with a company called Morris Technologies. We also got involved in the medical business. GE Aviation acquired our company, and we really became aviation-centric.

So, look, the reason I'm here I think in part is to give a perspective of a different industry, and perhaps some of the similarities and maybe more so the similarities and some of the differences between what you do in the medical world and what our experience has been in the aviation world, and specifically around additive metals is where I am going to concentrate a lot of my effort.

So the first two things, I think it's fair to say in two primary observations that we would make at GE is that, number one, when you're designing for additive, every element of the design process needs to be thought about differently. So we've kind of touched on that. We've heard that from a few presentations already, but this is really an important point. You can't generally take, at least in our world, we have found you cannot generally take a design that was meant for castings or fabrications or machining and think you are going to just be successfully producing the same part with an additive technology.

So we've learned that lesson very well on one of the parts I'll show you here today.

The other one is that from our perspective at least -- and this would of course be through the FAA -- that the qualification of additive is really no different than qualification of any new cast or forged alloy. That's a pretty significant statement from our perspective because what we're trying to say is we don't believe that the process itself should be certified, we believe still that the components we produce, the engines, should be certified, and that's a very important point for a lot of reasons. There are cost reasons and there are regulatory reasons, but at least in our world, that's how we view it, and we think and we hope that the FAA views it in a very similar way.

So let me just go through a little bit of our pedigree of where we've been with additive and some of the things that we use...

Ernesto Rios Director of Manufacturing Operations at Renovis Surgical Technologies discusses electron beam melting beginning on page 45.

Join the InvestorsHub Community

Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.