| Followers | 9 |

| Posts | 1597 |

| Boards Moderated | 1 |

| Alias Born | 01/27/2014 |

Friday, March 10, 2017 11:56:00 AM

Siemens produces 3D printed component for nuclear power station

The original article was at theengineer.com. A follow up article with additional information about GE, the DOE, additive manufacturing, and nuclear power was posted on the 3dprint.com site. The follow up is shown after the original post.

As the original design is “virtually impossible” to get, additively manufacturing it allows older plants, like NEK, to continue operating. A team of Siemens experts in Slovenia reverse-engineered the part, and created a “digital twin.”

The Siemens state-of-the-art additive manufacturing facility in Finspång, Sweden, which opened a little over a year ago and marked the company’s first foray into metal additive manufacturing, 3D printed the impeller.

From theengineer.co.uk - Siemens produces 3D printed component for nuclear power station - 9th March 2017

In a claimed first, engineers from Siemens have produced and installed a 3D-printed part in a nuclear power plant.

Siemens used Additive Manufacturing to produce a pump impeller for Slovenia’s Krško nuclear power plant.

The replacement part produced for the Krško nuclear power plant in Slovenia is a metallic, 108mm diameter impeller for a fire protection pump that is in constant rotating operation.

The original impeller was in operation since the plant was commissioned in 1981; but with its manufacturer is no longer in business and the designs no longer in existence, the Siemens team reverse-engineered the component and created a “digital twin” which was produced at the company’s additive manufacturing (AM) facility in Finspång, Sweden.

The original, obsolete water impeller alongside a 3D printed prototype and the resulting 3D-printed replacement.

Meeting the Krško NPP’s stringent quality and safety assurance requirements required extensive testing that was performed jointly with the Krško operations team over several months, ensuring that the new 3D-printed part would perform safely and reliably. Further material testing at an independent institute as well as a CT scan, showed that the material properties of the 3D-printed part were superior to those of the original part.

“The better than expected performance of this 3D-printed part gave us confidence that we can reach the full life expectancy from our asset,” said Vinko Planinc, head of maintenance at the Krško plant. ”

The Krško plant is among the highest-ranked of European nuclear power plants by the European Nuclear Safety Regulators Group in terms of safety according to assessments following Fukushima. It provides more than one-quarter of Slovenia’s and 15 per cent of Croatia’s power, making it vitally important to the region.

There's a related story from 3dprint.com that provides information on GE additive manufacturing for nuclear power. Siemens in Sweden seems to be first to score in this market. Siemens Completes First Successful Installation of 3D Printed Part in Nuclear Power Plant - March 9, 2017

It seems 3D printing is touching every single industry under the sun these days, including nuclear power plants. Regardless of how you feel about them, they do exist, and they are here to stay. It’s important to continue researching ways that additive manufacturing technology can benefit power plants, as the advancement of metal additive manufacturing can help produce components for these facilities in a more secure way. This summer, the US Department of Energy tapped GE to lead a $2 million additive manufacturing research project that’s relevant to advanced nuclear technology, and Russia’s nuclear energy corporation, Rosatom, is working to develop the first industrial metal 3D printer for the country’s nuclear industry. Today, global technology powerhouse Siemens announced that it has completed the first successful commercial installation, and continuing safe operation, of a 3D printed part inside a nuclear power plant.

This milestone is a nuclear industry breakthrough: the nuclear sector obviously has incredibly exacting reliability and safety requirements, so the fact that a 3D printed part made it through these standards is a big accomplishment. The 3D printed replacement part was produced for a plant that’s been in operation for over thirty years in Slovenia, the Krško Nuclear Power Plant (NEK).

In terms of safety, this power plant is ranked one of the highest of all European nuclear power plants by the European Nuclear Safety Regulators Group (ENSREG), an independent, expert advisory group. The Krško plant is of critical importance to the region, because it provides over 15% of Croatia’s power and more than 25% of Slovenia’s. This isn’t the first time Siemens has worked with the plant: the company has provided service and performed modifications on its non-nuclear side, including turbine and generator equipment, for over a decade.

The part Siemens worked with is a metallic impeller, with a diameter of 108 mm, for a fire protection pump that operates in a constant rotation and provides pressure for the plant’s fire protection system. The original impeller is pretty old: it’s been in use since the plant was commissioned back in 1981. The manufacturer of the original impeller isn’t even in business anymore, which made this obsolete, non-OEM part the perfect additive manufacturing test subject. As the original design is “virtually impossible” to get, additively manufacturing it allows older plants, like NEK, to continue operating. A team of Siemens experts in Slovenia reverse-engineered the part, and created a “digital twin.”

The Siemens state-of-the-art additive manufacturing facility in Finspång, Sweden, which opened a little over a year ago and marked the company’s first foray into metal additive manufacturing, 3D printed the impeller.

Tim Holt, CEO of Siemens Power Generation Services division, said, “We continue to push forward our investments and cutting-edge advancements in additive manufacturing and 3D printing. This achievement at the Krško nuclear power plant is another example of how the digital transformation and the data-driven capabilities we have are impacting the energy industry in ways that really matter. Additive manufacturing’s reduced lead times and faster production optimizes parts replacement and creates real value for our customers.”

In order to meet quality and safety assurance requirements, and make sure that the part would perform, the 3D printed impeller was put through extensive testing over several months, in collaboration with the operations team at the Krško plant. A CT scan and additional material testing took place at a separate, independent institution, and demonstrated that the 3D printed impeller’s material properties outmatched those of the original part.

“The better than expected performance of this 3D printed part gave us confidence that we can reach the full life expectancy from our asset. Siemens has a long history of innovation in this area and their dedication to providing their customers with the latest, proven innovations made them an excellent partner for this project,” said Vinko Planinc, Head of Maintenance at the Krško plant.

The Krško plant and Siemens are already looking for ways to advance the design of other parts that are hard to make with traditional manufacturing techniques, like lightweight structures that have improved cooling patterns. Discuss in the Siemens forum at 3DPB.com.

If you're interested to see more information about this specific power plant:

The Krško Nuclear Power Plant (NEK) website

From world-nuclear.org - Nuclear Power in Slovenia (Updated May 2016)

Nuclear power

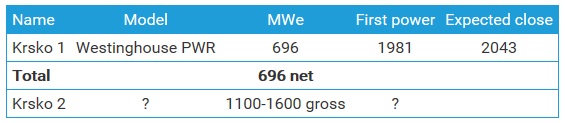

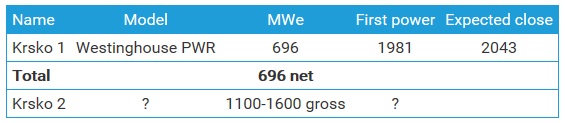

Slovenia has a 696 MWe Westinghouse nuclear reactor in operation, the NPP Krsko, which is jointly owned by Croatia. This pressurized water reactor was the first western nuclear power plant in eastern Europe. Construction started in 1975 and it was connected to the grid in 1981, entering commercial operation in 1983. In 2001 its steam generators were replaced and the plant was uprated 6% then and 3% subsequently. Its operational life was designed to be 40 years, but a 20-year extension was confirmed in mid-2015, subject to inspections in 2023 and 2033.

It is owned and operated by GEN Energija, which incorporates the Slovenian stake in Nuklearna Elektrarna Krško (NEK), a joint Slovene-Croat company operating Krsko.

Operating and proposed power reactors

A further Krsko unit is under consideration, of 1100 to 1600 MWe. An application towards a second reactor at the Krsko nuclear power plant was submitted to the country's ministry of economy by GEN Energija in January 2010. Parliament was expected to decide on this in 2011, and it remains an objective as JEK2 project. The cost is estimated at up to €5 billion, and it would be fully owned by Slovenia.

The first western nuclear power plant in eastern Europe was a Westinghouse designed plant, not GE.

At world-nuclear-news.org - 3D innovation for Sellafield - 15 May 2014

Sellafield Ltd is pressing cutting-edge 3D printing technology into service to help meet the challenges of decommissioning one of the world's oldest and most complex nuclear sites.

Sellafield's Donna Connor investigates the results of 3D printing (Image: Sellafield Ltd)

The original article was at theengineer.com. A follow up article with additional information about GE, the DOE, additive manufacturing, and nuclear power was posted on the 3dprint.com site. The follow up is shown after the original post.

As the original design is “virtually impossible” to get, additively manufacturing it allows older plants, like NEK, to continue operating. A team of Siemens experts in Slovenia reverse-engineered the part, and created a “digital twin.”

The Siemens state-of-the-art additive manufacturing facility in Finspång, Sweden, which opened a little over a year ago and marked the company’s first foray into metal additive manufacturing, 3D printed the impeller.

From theengineer.co.uk - Siemens produces 3D printed component for nuclear power station - 9th March 2017

In a claimed first, engineers from Siemens have produced and installed a 3D-printed part in a nuclear power plant.

Siemens used Additive Manufacturing to produce a pump impeller for Slovenia’s Krško nuclear power plant.

The replacement part produced for the Krško nuclear power plant in Slovenia is a metallic, 108mm diameter impeller for a fire protection pump that is in constant rotating operation.

The original impeller was in operation since the plant was commissioned in 1981; but with its manufacturer is no longer in business and the designs no longer in existence, the Siemens team reverse-engineered the component and created a “digital twin” which was produced at the company’s additive manufacturing (AM) facility in Finspång, Sweden.

The original, obsolete water impeller alongside a 3D printed prototype and the resulting 3D-printed replacement.

Meeting the Krško NPP’s stringent quality and safety assurance requirements required extensive testing that was performed jointly with the Krško operations team over several months, ensuring that the new 3D-printed part would perform safely and reliably. Further material testing at an independent institute as well as a CT scan, showed that the material properties of the 3D-printed part were superior to those of the original part.

“The better than expected performance of this 3D-printed part gave us confidence that we can reach the full life expectancy from our asset,” said Vinko Planinc, head of maintenance at the Krško plant. ”

The Krško plant is among the highest-ranked of European nuclear power plants by the European Nuclear Safety Regulators Group in terms of safety according to assessments following Fukushima. It provides more than one-quarter of Slovenia’s and 15 per cent of Croatia’s power, making it vitally important to the region.

There's a related story from 3dprint.com that provides information on GE additive manufacturing for nuclear power. Siemens in Sweden seems to be first to score in this market. Siemens Completes First Successful Installation of 3D Printed Part in Nuclear Power Plant - March 9, 2017

It seems 3D printing is touching every single industry under the sun these days, including nuclear power plants. Regardless of how you feel about them, they do exist, and they are here to stay. It’s important to continue researching ways that additive manufacturing technology can benefit power plants, as the advancement of metal additive manufacturing can help produce components for these facilities in a more secure way. This summer, the US Department of Energy tapped GE to lead a $2 million additive manufacturing research project that’s relevant to advanced nuclear technology, and Russia’s nuclear energy corporation, Rosatom, is working to develop the first industrial metal 3D printer for the country’s nuclear industry. Today, global technology powerhouse Siemens announced that it has completed the first successful commercial installation, and continuing safe operation, of a 3D printed part inside a nuclear power plant.

This milestone is a nuclear industry breakthrough: the nuclear sector obviously has incredibly exacting reliability and safety requirements, so the fact that a 3D printed part made it through these standards is a big accomplishment. The 3D printed replacement part was produced for a plant that’s been in operation for over thirty years in Slovenia, the Krško Nuclear Power Plant (NEK).

In terms of safety, this power plant is ranked one of the highest of all European nuclear power plants by the European Nuclear Safety Regulators Group (ENSREG), an independent, expert advisory group. The Krško plant is of critical importance to the region, because it provides over 15% of Croatia’s power and more than 25% of Slovenia’s. This isn’t the first time Siemens has worked with the plant: the company has provided service and performed modifications on its non-nuclear side, including turbine and generator equipment, for over a decade.

The part Siemens worked with is a metallic impeller, with a diameter of 108 mm, for a fire protection pump that operates in a constant rotation and provides pressure for the plant’s fire protection system. The original impeller is pretty old: it’s been in use since the plant was commissioned back in 1981. The manufacturer of the original impeller isn’t even in business anymore, which made this obsolete, non-OEM part the perfect additive manufacturing test subject. As the original design is “virtually impossible” to get, additively manufacturing it allows older plants, like NEK, to continue operating. A team of Siemens experts in Slovenia reverse-engineered the part, and created a “digital twin.”

The Siemens state-of-the-art additive manufacturing facility in Finspång, Sweden, which opened a little over a year ago and marked the company’s first foray into metal additive manufacturing, 3D printed the impeller.

Tim Holt, CEO of Siemens Power Generation Services division, said, “We continue to push forward our investments and cutting-edge advancements in additive manufacturing and 3D printing. This achievement at the Krško nuclear power plant is another example of how the digital transformation and the data-driven capabilities we have are impacting the energy industry in ways that really matter. Additive manufacturing’s reduced lead times and faster production optimizes parts replacement and creates real value for our customers.”

In order to meet quality and safety assurance requirements, and make sure that the part would perform, the 3D printed impeller was put through extensive testing over several months, in collaboration with the operations team at the Krško plant. A CT scan and additional material testing took place at a separate, independent institution, and demonstrated that the 3D printed impeller’s material properties outmatched those of the original part.

“The better than expected performance of this 3D printed part gave us confidence that we can reach the full life expectancy from our asset. Siemens has a long history of innovation in this area and their dedication to providing their customers with the latest, proven innovations made them an excellent partner for this project,” said Vinko Planinc, Head of Maintenance at the Krško plant.

The Krško plant and Siemens are already looking for ways to advance the design of other parts that are hard to make with traditional manufacturing techniques, like lightweight structures that have improved cooling patterns. Discuss in the Siemens forum at 3DPB.com.

If you're interested to see more information about this specific power plant:

The Krško Nuclear Power Plant (NEK) website

From world-nuclear.org - Nuclear Power in Slovenia (Updated May 2016)

Nuclear power

Slovenia has a 696 MWe Westinghouse nuclear reactor in operation, the NPP Krsko, which is jointly owned by Croatia. This pressurized water reactor was the first western nuclear power plant in eastern Europe. Construction started in 1975 and it was connected to the grid in 1981, entering commercial operation in 1983. In 2001 its steam generators were replaced and the plant was uprated 6% then and 3% subsequently. Its operational life was designed to be 40 years, but a 20-year extension was confirmed in mid-2015, subject to inspections in 2023 and 2033.

It is owned and operated by GEN Energija, which incorporates the Slovenian stake in Nuklearna Elektrarna Krško (NEK), a joint Slovene-Croat company operating Krsko.

Operating and proposed power reactors

A further Krsko unit is under consideration, of 1100 to 1600 MWe. An application towards a second reactor at the Krsko nuclear power plant was submitted to the country's ministry of economy by GEN Energija in January 2010. Parliament was expected to decide on this in 2011, and it remains an objective as JEK2 project. The cost is estimated at up to €5 billion, and it would be fully owned by Slovenia.

The first western nuclear power plant in eastern Europe was a Westinghouse designed plant, not GE.

At world-nuclear-news.org - 3D innovation for Sellafield - 15 May 2014

Sellafield Ltd is pressing cutting-edge 3D printing technology into service to help meet the challenges of decommissioning one of the world's oldest and most complex nuclear sites.

Sellafield's Donna Connor investigates the results of 3D printing (Image: Sellafield Ltd)

Join the InvestorsHub Community

Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.