Register for free to join our community of investors and share your ideas. You will also get access to streaming quotes, interactive charts, trades, portfolio, live options flow and more tools.

Graphene Council identifies Versarien as quality graphene maker.

https://www.compositesworld.com/blog/post/nanomaterials-products-supply-chain-mature-for-next-gen-composites

6/26/2019

Nanomaterials: Products, supply chain mature for next-gen composites

Verifying producers and supporting developers

One of the challenges facing a dynamic, fast-maturing technology is to build trust in the supply chain. To that end, the Graphene Council is working to mature the global supply chain through its Verified Graphene Producer program. Versarien plc (Cheltenham, U.K.) is the first graphene supplier to successfully complete this independent, third-party verification system that involves a physical inspection of the production facilities and review of the entire production process and safety procedures. “We also take random samples of their products and submit them for blind testing to be rigorously characterized at the National Physical Laboratory (NPL, Teddington, U.K.), a world-class institution that follows ISO/TR 19733:2019 for Nanotechnologies,” says the Graphene Council’s Barkan. NADCAP is an analogous audit program long used by the aerospace industry for the same purpose. “Without this type of program, customers have no clue what they are getting when they buy and receive graphene products,” says Barkan. “Our Verified Graphene Producer program is an important step to provide a level of confidence in the both products and producers worldwide.”

The Graphene Council also works to improve development of graphene applications. “We connect companies with resources to help them quickly navigate products, producers, materials science and testing for faster, more successful development,” says Barkan. “We also provide independent, third-party advisory services to help companies that want to use graphene, but don’t know where to start. We not only have reach into our formal members, but also track more than 200 companies involved with graphene worldwide. We monitor what is being developed and the latest scientific and research results, helping to understand what type of graphene to use, how to functionalize and disperse it and how to test for performance.” He notes a close relationship with the Graphene Engineering & Innovation Center (GEIC) at the University of Manchester (Manchester, UK), where graphene was first discovered. “This is a rapid prototyping center,” says Barkan, “and helps us to leverage what graphene can do.”

Summary for those interested in Versarien:

Versarien PLC is the first graphene company in the world to successfully complete the US based Graphene Council's "Verified Graphene Producer” programme.

Versarien produces, develops and commercialises advanced materials technology with graphene (brand name: Nanene), graphene electrically conductive ink (brand name: Graphinks) and boron nitride (brand name: Hexotene) currently core products. There are however, many further materials being researched by the company which could have equally have amazing qualities.

It is a British Company and listed on the London AIM market under the ticker VRS.

Link to the website: http://www.versarien.com/

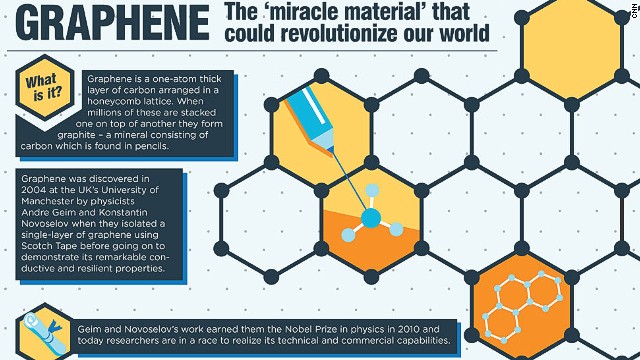

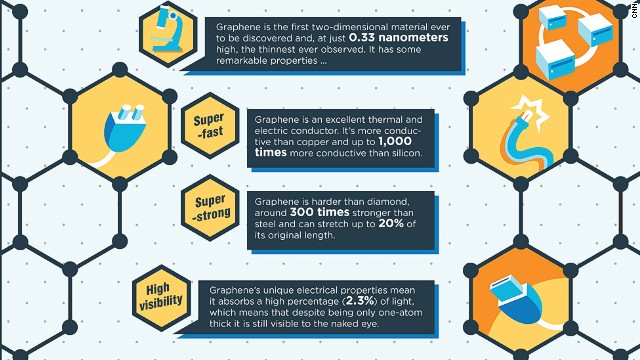

Discovered in 2004 at the University of Manchester, graphene is a single layer of graphite arranged in a hexagonal lattice. At 200x stronger than steel it is the strongest known material, yet it's also stretchy. It is better at carrying electricity and heat than any other material, better by far than silver and copper. It is optically transparent, yet so dense that it is impermeable to gases so even helium, the smallest gas atom, cannot pass through it.

Graphene can create multiple benefits in multiple industries. Here are a few examples based on proven applications:

Construction:

Adding a small amount of graphene to cement makes concrete that is 30% stronger allowing buildings and other structures to be made using less material, increasing efficiently with lower costs and much improved environmental impact. Adding graphene to asphalt improves the wear resistance by over 200% and extends the service life of roads.

Aerospace:

Graphene enhanced composites are significantly stronger for the same mass of material. This allows ‘Lightweighting’ meaning less material is needed allowing greater fuel economy and greater range.

Automotive:

Graphene can drastically reduce the weight of vehicles allowing better fuel efficiency while graphene paint provides an ultra-strong coating which is impermeable to gas, water and chemicals, meaning rust could be a thing of the past. Graphene can be used in battery technology to enhance efficiency allowing electric vehicles greater range and faster charging.

Packaging:

It has several properties that lend themselves well to food packaging by acting as a barrier to oxygen and moisture therefore increasing the life of the product, and features both conductivity for antistatic packaging and stiffness for added strength achieving the same mechanical performance using less plastic, and is recyclable.

This is just a very small fraction of the uses for graphene advanced materials that you can use right now.

The pace of change in this emerging industry is astonishing. Whole industries of the future are being based around the use of graphene and these will play a key role in generating economic benefits to those that embrace this exciting advanced materials approach.

Competition:

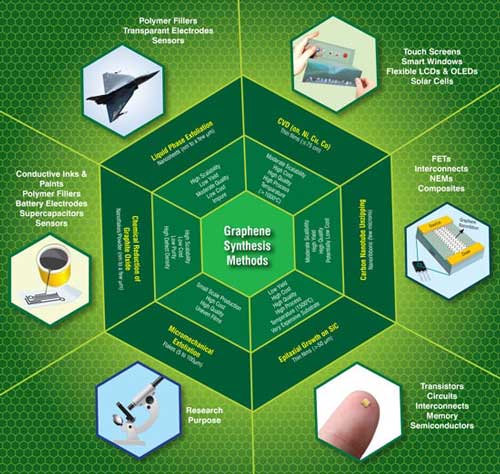

2D graphene material must be less than 11 layers thick, and anything above is bulk material (graphite). It is very difficult to produce high quality graphene cost effectively at commercial scale, which is why there are many companies which claim to produce graphene, but 95% of them produce multi-layer graphene nano platelets, which is relatively easy to do.

The range of gains from graphene declines rapidly when you move above 10 layers, which is why we are delighted that the ISO standards have just been published. Many of the so called graphene producers will no longer be able to call their product graphene.

Versarien is the first graphene company in the world to successfully complete the US based Graphene Council's "Verified Graphene Producer" programme which provides end-users with a degree of confidence that has not existed before, that they are sourcing material from a reputable supplier capable of producing genuine graphene cost effectively at a commercial scale.

?Many of the companies currently claiming to be producers have serious financial problems. Versarien is 'lucky' to have many arms to the company, including 'traditional' profit making companies which have supported 2DTech through its infancy.

Versarien’s financials:

Review based on Announced Interim Results•

Cash of £6.07 million at 30 September 2018 (30 September 2017: £0.35 million) following? successful fund raising of £5.15 million gross in September 2018•

In October 2018, Versarien completed its acquisition of 62% of the Spanish company Gnanomat?S.L. for £2,647,000 of which £673,000 in cash and £1,974,000 in shares. In addition VRS willprovide a convertible loan to GNA of €750,000 in September 2019 and £500,000 in March 2020.•

Cash used from operations before working capital changes was £375,000 being a monthly cash?consumption of £63,000.•

Free cash is considered to be the excess of a minimum of £1m headroom and the GNA?commitment of £1.1m so free cash at 30 September was £4m which at the H1 burn rate of?£63,000 per month provides circa 5 years operational cash before any increased opex, capex etc

Company Objectives:

VRS's chosen areas initially for developing their graphene technology are carbon fibre composites, polymers and batteries.

The CEO Neill Ricketts has stated in many interviews that he wants VRS to become a huge company. They intend to do this by:

Concentrating (though not exclusively) on 5 main existing collaborations to bring them to the stage where they are producing graphene in commercial quantities for specific applications.??

Establishing new licence arrangements with research institutions and acquiring majority stakes in companies whose intellectual property fits with their definition of advanced materials technology and are capable of commercialising graphene applications and

Continuing to identify opportunities for international expansion.

Connections:

Versarien have links with all the great UK universities including Manchester and Cambridge and now Madrid university too thanks to the Gnanomat acquisition, Versarien have a licensed process from the University of Ulster with 60% ownership of IP.

They are a Tier 1 partner of the Graphene Engineering Innovation Centre

They are a project partner with the National Graphene Institute

They have 2 UK Government secondees and around 38 collaborations

They have good working relationships with The Warwick Manufacturing Group, The Energy Innovation Centre, Scafell Organics Ltd, Fern Plastics Ltd, Luxus Ltd and many more.

Then there is their range of products... Nanene, Hexotene, Graphinks and Polgrene just to get us going...many more 2D materials are being worked on as we speak. Then of course moving up the value chain we have Gnanomat and AAC Cryoma....

They currently produce Nanene enhanced earphones which are being sold by MediaDevil and are at an advanced stage of launching a range of mobile phone and tablet device accessories utilising Nanene.

https://mediadevil.com/products/artisanphonics-cb-01-nanene-graphene-wood-earphones

Validation of Versarien's products and people:

-First graphene company in the world to successfully complete the Graphene Council's "Verified Graphene Producer" programme.

-It has been independently tested by the University of Manchester and we believe it to be the highest quality graphene product on the market today.

-The patented process that is used to manufacture Nanene produces high quality graphene nano-platelets with a majority of sub 10 layers and a significant number of sub 5 layers material. This gives Nanene its incredible performance benefits. The quality of this process has been independently verified by several leading United Kingdom universities.

-They have been successful in all the tenders entered into to supply the UK Government’s Centre for Process Innovation with nanomaterials after a competitive process.

-Versarien has been appointed as the inaugural Industry Council member and Corporate Partner of The National Graphene Association ("NGA"), the main organisation and body in the US advocating and promoting the commercialisation of graphene. It was also selected to be The Graphene Council's launch client for their 'Verified Graphene Producer’ programme to independently verify that the Company's Nanene graphene nano platelets meet their demanding standards.

-The quality of their Nanene graphene nano platelets has been satisfactorily tested by the Chinese National Graphene Product Quality Supervision and Inspection Centre (NGSIC) in Wuxi and more importantly the Chinese appear to prefer their graphene over that of the many producers in China.

-Perhaps one of the greatest validations however, is that Dr Denis Koltsov and Dr Martin Kemp who worked on the ISO graphene standards then chose to go and work for the company.

So far they have had no collaborations fail due to product performance.

Summary for those interested in Versarien:

Versarien PLC is the first graphene company in the world to successfully complete the US based Graphene Council's "Verified Graphene Producer” programme.

Versarien produces, develops and commercialises advanced materials technology with graphene (brand name: Nanene), graphene electrically conductive ink (brand name: Graphinks) and boron nitride (brand name: Hexotene) currently core products. There are however, many further materials being researched by the company which could have equally have amazing qualities.

It is a British Company and listed on the London AIM market under the ticker VRS.

Link to the website: http://www.versarien.com/

Discovered in 2004 at the University of Manchester, graphene is a single layer of graphite arranged in a hexagonal lattice. At 200x stronger than steel it is the strongest known material, yet it's also stretchy. It is better at carrying electricity and heat than any other material, better by far than silver and copper. It is optically transparent, yet so dense that it is impermeable to gases so even helium, the smallest gas atom, cannot pass through it.

Graphene can create multiple benefits in multiple industries. Here are a few examples based on proven applications:

Construction:

Adding a small amount of graphene to cement makes concrete that is 30% stronger allowing buildings and other structures to be made using less material, increasing efficiently with lower costs and much improved environmental impact. Adding graphene to asphalt improves the wear resistance by over 200% and extends the service life of roads.

Aerospace:

Graphene enhanced composites are significantly stronger for the same mass of material. This allows ‘Lightweighting’ meaning less material is needed allowing greater fuel economy and greater range.

Automotive:

Graphene can drastically reduce the weight of vehicles allowing better fuel efficiency while graphene paint provides an ultra-strong coating which is impermeable to gas, water and chemicals, meaning rust could be a thing of the past. Graphene can be used in battery technology to enhance efficiency allowing electric vehicles greater range and faster charging.

Packaging:

It has several properties that lend themselves well to food packaging by acting as a barrier to oxygen and moisture therefore increasing the life of the product, and features both conductivity for antistatic packaging and stiffness for added strength achieving the same mechanical performance using less plastic, and is recyclable.

This is just a very small fraction of the uses for graphene advanced materials that you can use right now.

The pace of change in this emerging industry is astonishing. Whole industries of the future are being based around the use of graphene and these will play a key role in generating economic benefits to those that embrace this exciting advanced materials approach.

Competition:

2D graphene material must be less than 11 layers thick, and anything above is bulk material (graphite). It is very difficult to produce high quality graphene cost effectively at commercial scale, which is why there are many companies which claim to produce graphene, but 95% of them produce multi-layer graphene nano platelets, which is relatively easy to do.

The range of gains from graphene declines rapidly when you move above 10 layers, which is why we are delighted that the ISO standards have just been published. Many of the so called graphene producers will no longer be able to call their product graphene.

Versarien is the first graphene company in the world to successfully complete the US based Graphene Council's "Verified Graphene Producer" programme which provides end-users with a degree of confidence that has not existed before, that they are sourcing material from a reputable supplier capable of producing genuine graphene cost effectively at a commercial scale.

?Many of the companies currently claiming to be producers have serious financial problems. Versarien is 'lucky' to have many arms to the company, including 'traditional' profit making companies which have supported 2DTech through its infancy.

Versarien’s financials: ?

Review based on Announced Interim Results?•

Cash of £6.07 million at 30 September 2018 (30 September 2017: £0.35 million) following? successful fund raising of £5.15 million gross in September 2018?•

In October 2018, Versarien completed its acquisition of 62% of the Spanish company Gnanomat?S.L. for £2,647,000 of which £673,000 in cash and £1,974,000 in shares. In addition VRS will?provide a convertible loan to GNA of €750,000 in September 2019 and £500,000 in March 2020.?•

Cash used from operations before working capital changes was £375,000 being a monthly cash?consumption of £63,000.?•

Free cash is considered to be the excess of a minimum of £1m headroom and the GNA?commitment of £1.1m so free cash at 30 September was £4m which at the H1 burn rate of?£63,000 per month provides circa 5 years operational cash before any increased opex, capex etc

Company Objectives:?

VRS's chosen areas initially for developing their graphene technology are carbon fibre composites, polymers and batteries.??

The CEO Neill Ricketts has stated in many interviews that he wants VRS to become a huge company. They intend to do this by:??

Concentrating (though not exclusively) on 5 main existing collaborations to bring them to the stage where they are producing graphene in commercial quantities for specific applications.??

Establishing new licence arrangements with research institutions and acquiring majority stakes in companies whose intellectual property fits with their definition of advanced materials technology and are capable of commercialising graphene applications and

Continuing to identify opportunities for international expansion.??

Connections: ?

Versarien have links with all the great UK universities including Manchester and Cambridge and now Madrid university too thanks to the Gnanomat acquisition, Versarien have a licensed process from the University of Ulster with 60% ownership of IP.??

They are a Tier 1 partner of the Graphene Engineering Innovation Centre

They are a project partner with the National Graphene Institute

They have 2 UK Government secondees and around 38 collaborations

They have good working relationships with The Warwick Manufacturing Group, The Energy Innovation Centre, Scafell Organics Ltd, Fern Plastics Ltd, Luxus Ltd and many more.??

Then there is their range of products... Nanene, Hexotene, Graphinks and Polgrene just to get us going...many more 2D materials are being worked on as we speak. Then of course moving up the value chain we have Gnanomat and AAC Cryoma....

They currently produce Nanene enhanced earphones which are being sold by MediaDevil and are at an advanced stage of launching a range of mobile phone and tablet device accessories utilising Nanene.

https://mediadevil.com/products/artisanphonics-cb-01-nanene-graphene-wood-earphones

?

Validation of Versarien's products and people:

-First graphene company in the world to successfully complete the Graphene Council's "Verified Graphene Producer" programme.

?

-It has been independently tested by the University of Manchester and we believe it to be the highest quality graphene product on the market today.

?

-The patented process that is used to manufacture Nanene produces high quality graphene nano-platelets with a majority of sub 10 layers and a significant number of sub 5 layers material. This gives Nanene its incredible performance benefits. The quality of this process has been independently verified by several leading United Kingdom universities.

?

-They have been successful in all the tenders entered into to supply the UK Government’s Centre for Process Innovation with nanomaterials after a competitive process.

?

-Versarien has been appointed as the inaugural Industry Council member and Corporate Partner of The National Graphene Association ("NGA"), the main organisation and body in the US advocating and promoting the commercialisation of graphene. It was also selected to be The Graphene Council's launch client for their 'Verified Graphene Producer’ programme to independently verify that the Company's Nanene graphene nano platelets meet their demanding standards.

?

-The quality of their Nanene graphene nano platelets has been satisfactorily tested by the Chinese National Graphene Product Quality Supervision and Inspection Centre (NGSIC) in Wuxi and more importantly the Chinese appear to prefer their graphene over that of the many producers in China.

?

-Perhaps one of the greatest validations however, is that Dr Denis Koltsov and Dr Martin Kemp who worked on the ISO graphene standards then chose to go and work for the company.

So far they have had no collaborations fail due to product performance.??

List of Collaborations:??

1. 20/4/16 -Nanene enhanced battery collaboration with Warwick Manufacturing Group

2. 11/5/16 -Carbon fibre collaboration with Bromley Technology

3. 14/6/16 -Carbon fibre collab’ with Absolute Engineering?

4. 23/6/16 -N enhanced composites for aerospace components with CT Engineering (supply Airbus)

?5. 14/12/16 -N enhanced PAEK materials with Scafell Organics Ltd (polymers for auto & aero industries)?

6. 19/12/16 -N enhanced PAEK materials with Fern Plastic Products (injection moulded products)

7. 3/10/17 -Collab with Israel Aerospace?

8&9. 17/11/17 -Collabs with 2 of the world’s largest consumer groups to make N enhanced polymers for packaging

10. 4/12/17 -Agreement with US Fortune 100 chemical supplier - N and other 2D products in packaging?

11. 8/1/18 -Agreement with Global Apparel manufacturer (HQ Asia) - fabrics & high perf sportswear -INKS

12. 15/1/18 -LOI with Jinan/Shandong - planned Chinese manufacturing facility?

13. 27/2/18 -Collab with VivoBarefoot - N enhanced resins & fibres for footwear?

14. 14/3/18 -Collab with Team Sky - cycling products using N & INKS?

15. 27/3/18 -Collab with a world leading aerospace group - engines & mechanical systems & sensory devices - propeller initial £200k

?

16. 16/4/18 -European tyre manufacturer - initial order 500gr

17. 30/4/18 -Agreement with LUXUS (UK plastics manufacturer) N enhanced polymers for packaging, automotive, civil engineering sectors (AAC Cryoma, WMG)?

18. 29/5/18 -FTSE listed European manufacturer of consumer products for personal & household goods?

19. 8/6/18 -Collab with ArrowGreenTech - graphinks for PVA film, N banknotes & passports - (both exclusives) -tyre & rubber sectors (exclusive India only), 1st refusal on manufacturing plant in India

20. 18/6/18 -Collab with MediaDevil earplugs

?

21. 2/7/18 -Zap&Go supercapacitators

22. 2/7/18 -Flexibat - thin batteries for wearable devices (£145k funding granted)?

23. 2/8/18 -Collab with a top sportswear manufacturer - footwear & textiles?

24. 20/8/18 -Collab with AXIA - composite mats & smart graphene devices (N & INKS), S Korea, smart buildings & EVs?

25. 24/8/18 -AECOM US Fortune 500, large civil engineering structures - first SOW confirmed which includes the supply of 50 kg of graphene enhanced polymer material to be delivered in early December 2018 and a further 200kg early Jan '19 for final testing.

26. 1/10/18 -Completion of acquisition and collab with Gnanomat utilising Nanene for energy storage devices for use in EVs and portable electronic devices?

27. 18/10/18 -Collab with Advanced Insulation Ltd - sub-sea insulation materials, with a view to improving their tear resistance and reducing water absorption.?

28. 4/11/18 -Agreement with Qingdao Municipal Bureau of Commerce - Q to become one of the principal places to develop VRS' market in China - Q will assist VRS to form relationships with local businesses & identify investors - Q will help form a "Sino-foreign joint venture" which may include capital contributions.?

29. 7/11/18 -MOU with Tunghsu Optoelectronic Technology Ltd - upgraded to an LOI on 14/03/19 - the companies are to work together to manufacture in China new generation graphene heaters based on the micro-flow graphene ink technology and to develop other products utilising a variety of 2d materials, including graphene-enhanced sports equipment and smart wearable devices.

?

30. 15/11/18 -Major Global Airline - order for the supply of Versarien's graphene nanoplatelets to a design and manufacturing company for use in fire retardant aircraft interior parts which have gained the necessary certification from a Federal Aviation Administration (FAA) certified, fire testing laboratory.?

31. 19/11/18 - MOU with Jinan High-tech Financial Investment Co., Ltd - to establish a joint venture for the manufacture and sale of the Company's Nanene, Graphinks and other related graphene products in Jinan.?

32. - 04/12/18 -Polygrene launch - to enable us to offer customers an already compounded material incorporating graphene that they can use in existing production processes.

?

33. - 05/12/18 -MOU with China Tiesiju Civil Engineering Group Co Ltd. ("CTCE"), a subsidiary of China Railway Group Limited ("CRG"). - for use in anticorrosive and fireproof coatings, heat conductive and heating materials for the temperature control of structures, sensors for the mechanical monitoring of engineering structures, special engineering plastics, rubber and asphalt.?

34. 17/12/18 -GNA patent awarded which will enable the development of the technology needed to produce commercially viable graphene enhanced batteries and other energy storage devices.?

35. 09/12/18- Collab with large state-owned Chinese Aerospace Co. Nanene and other 2d materials including Hexotene.

36. 04/02/19 -MOU signed with another of China's Fortune 500 building materials companies to use our powders and inks for in flame-retardant applications, conductive shielding applications, the development and manufacture of new generation graphene heaters using graphene inks, winter sports equipment, specifically targeted at the 2022 Winter Olympic Games, smart wearable devices, including sensors and smart earphones, the incorporation of graphene into concrete, anti-corrosion coatings, 3D printing of concrete and certain rail projects, solar energy, photovoltaic cells and smart buildings and Gnanomat's proprietary nanomaterials into supercapacitors and lithium-ion batteries. Nanene graphene nano platelets has been satisfactorily tested by NGSIC.?

37. 07/03/19 - MOU with a second large state-owned Chinese aerospace company focussed on developing additional innovative products incorporating Nanene in to film materials and sensors.

38. Term Sheet with Beijing Institute of Graphene Technology which envisages that BIGT will provide funding to Versarien to establish a subsidiary company in China in the form of an equity investment in the Company, providing BIGT with a holding of up to 15% of the issued share capital of the Company.

The Team:

CEO - Neill Ricketts

CFO - Chris Leigh

Head of Commerce - David Kerr

NED - Iain Gray

Consultant- Nigel Laughton

Head of International Strategy and Government Relations - Matt Walker (secondee: Dept’ International Trade)

Deputy Head of International Strategy and Government Relations - Yi Luo (secondee: Dept’ International Trade)

Head of Research - Dr Stephen Hodge

Heads of Technology - Dr Denis Koltsov and Dr Martin Kemp

Cambridge Graphene Consultant - Mark Shepherd

Cambridge graphene technology Advisor - Professor Andrea Ferrari

Nomad & Broker - Cannacord Genuity Ltd

China contact - Bruno

Korean contact - Rachel Yeong-Mee Kim

Vice President of North American Operations - Patrick Abbott

Hi Grabster good to see you posting on here. VRS has a huge following in the UK, & has been a superb investment for those of us who bought in 2017.

The only real Verified Graphene producer in the world, with scaleable production.

Notification of the first large order should see this much higher.

Summary for those new to Versarien

Versarien PLC is the first graphene company in the world to successfully complete the US based Graphene Council's "Verified Graphene Producer” programme.

Versarien produces, develops and commercialises advanced materials technology with graphene (brand name: Nanene), graphene electrically conductive ink (brand name: Graphinks) and boron nitride (brand name: Hexotene) currently core products. There are however, many further materials being researched by the company which could have equally have amazing qualities.

It is a British Company and listed on the London AIM market under the ticker VRS.

Link to the website: http://www.versarien.com/

Discovered in 2004 at the University of Manchester, graphene is a single layer of graphite arranged in a hexagonal lattice. At 200x stronger than steel it is the strongest known material, yet it's also stretchy. It is better at carrying electricity and heat than any other material, better by far than silver and copper. It is optically transparent, yet so dense that it is impermeable to gases so even helium, the smallest gas atom, cannot pass through it.

Graphene can create multiple benefits in multiple industries. Here are a few examples based on proven applications:

Construction:

Adding a small amount of graphene to cement makes concrete that is 30% stronger allowing buildings and other structures to be made using less material, increasing efficiently with lower costs and much improved environmental impact. Adding graphene to asphalt improves the wear resistance by over 200% and extends the service life of roads.

Aerospace:

Graphene enhanced composites are significantly stronger for the same mass of material. This allows ‘Lightweighting’ meaning less material is needed allowing greater fuel economy and greater range.

Automotive:

Graphene can drastically reduce the weight of vehicles allowing better fuel efficiency while graphene paint provides an ultra-strong coating which is impermeable to gas, water and chemicals, meaning rust could be a thing of the past. Graphene can be used in battery technology to enhance efficiency allowing electric vehicles greater range and faster charging.

Packaging:

It has several properties that lend themselves well to food packaging by acting as a barrier to oxygen and moisture therefore increasing the life of the product, and features both conductivity for antistatic packaging and stiffness for added strength achieving the same mechanical performance using less plastic, and is recyclable.

This is just a very small fraction of the uses for graphene advanced materials that you can use right now.

The pace of change in this emerging industry is astonishing. Whole industries of the future are being based around the use of graphene and these will play a key role in generating economic benefits to those that embrace this exciting advanced materials approach.

Competition:

2D graphene material must be less than 11 layers thick, and anything above is bulk material (graphite). It is very difficult to produce high quality graphene cost effectively at commercial scale, which is why there are many companies which claim to produce graphene, but 95% of them produce multi-layer graphene nano platelets, which is relatively easy to do.

The range of gains from graphene declines rapidly when you move above 10 layers, which is why we are delighted that the ISO standards have just been published. Many of the so called graphene producers will no longer be able to call their product graphene.

Versarien is the first graphene company in the world to successfully complete the US based Graphene Council's "Verified Graphene Producer" programme which provides end-users with a degree of confidence that has not existed before, that they are sourcing material from a reputable supplier capable of producing genuine graphene cost effectively at a commercial scale.

?Many of the companies currently claiming to be producers have serious financial problems. Versarien is 'lucky' to have many arms to the company, including 'traditional' profit making companies which have supported 2DTech through its infancy.

Versarien’s financials: ?

Review based on Announced Interim Results?•

Cash of £6.07 million at 30 September 2018 (30 September 2017: £0.35 million) following? successful fund raising of £5.15 million gross in September 2018?•

In October 2018, Versarien completed its acquisition of 62% of the Spanish company Gnanomat?S.L. for £2,647,000 of which £673,000 in cash and £1,974,000 in shares. In addition VRS will?provide a convertible loan to GNA of €750,000 in September 2019 and £500,000 in March 2020.?•

Cash used from operations before working capital changes was £375,000 being a monthly cash?consumption of £63,000.?•

Free cash is considered to be the excess of a minimum of £1m headroom and the GNA?commitment of £1.1m so free cash at 30 September was £4m which at the H1 burn rate of?£63,000 per month provides circa 5 years operational cash before any increased opex, capex etc

Company Objectives:?

VRS's chosen areas initially for developing their graphene technology are carbon fibre composites, polymers and batteries.??

The CEO Neill Ricketts has stated in many interviews that he wants VRS to become a huge company. They intend to do this by:??

Concentrating (though not exclusively) on 5 main existing collaborations to bring them to the stage where they are producing graphene in commercial quantities for specific applications.??

Establishing new licence arrangements with research institutions and acquiring majority stakes in companies whose intellectual property fits with their definition of advanced materials technology and are capable of commercialising graphene applications and

Continuing to identify opportunities for international expansion.??

Connections: ?

Versarien have links with all the great UK universities including Manchester and Cambridge and now Madrid university too thanks to the Gnanomat acquisition, Versarien have a licensed process from the University of Ulster with 60% ownership of IP.??

They are a Tier 1 partner of the Graphene Engineering Innovation Centre

They are a project partner with the National Graphene Institute

They have 2 UK Government secondees and around 38 collaborations

They have good working relationships with The Warwick Manufacturing Group, The Energy Innovation Centre, Scafell Organics Ltd, Fern Plastics Ltd, Luxus Ltd and many more.??

Then there is their range of products... Nanene, Hexotene, Graphinks and Polgrene just to get us going...many more 2D materials are being worked on as we speak. Then of course moving up the value chain we have Gnanomat and AAC Cryoma....

They currently produce Nanene enhanced earphones which are being sold by MediaDevil and are at an advanced stage of launching a range of mobile phone and tablet device accessories utilising Nanene.

https://mediadevil.com/products/artisanphonics-cb-01-nanene-graphene-wood-earphones

?

Validation of Versarien's products and people:

-First graphene company in the world to successfully complete the Graphene Council's "Verified Graphene Producer" programme.

?

-It has been independently tested by the University of Manchester and we believe it to be the highest quality graphene product on the market today.

?

-The patented process that is used to manufacture Nanene produces high quality graphene nano-platelets with a majority of sub 10 layers and a significant number of sub 5 layers material. This gives Nanene its incredible performance benefits. The quality of this process has been independently verified by several leading United Kingdom universities.

?

-They have been successful in all the tenders entered into to supply the UK Government’s Centre for Process Innovation with nanomaterials after a competitive process.

?

-Versarien has been appointed as the inaugural Industry Council member and Corporate Partner of The National Graphene Association ("NGA"), the main organisation and body in the US advocating and promoting the commercialisation of graphene. It was also selected to be The Graphene Council's launch client for their 'Verified Graphene Producer’ programme to independently verify that the Company's Nanene graphene nano platelets meet their demanding standards.

?

-The quality of their Nanene graphene nano platelets has been satisfactorily tested by the Chinese National Graphene Product Quality Supervision and Inspection Centre (NGSIC) in Wuxi and more importantly the Chinese appear to prefer their graphene over that of the many producers in China.

?

-Perhaps one of the greatest validations however, is that Dr Denis Koltsov and Dr Martin Kemp who worked on the ISO graphene standards then chose to go and work for the company.

So far they have had no collaborations fail due to product performance.??

List of Collaborations:??

1. 20/4/16 -Nanene enhanced battery collaboration with Warwick Manufacturing Group

2. 11/5/16 -Carbon fibre collaboration with Bromley Technology

3. 14/6/16 -Carbon fibre collab’ with Absolute Engineering?

4. 23/6/16 -N enhanced composites for aerospace components with CT Engineering (supply Airbus)

?5. 14/12/16 -N enhanced PAEK materials with Scafell Organics Ltd (polymers for auto & aero industries)?

6. 19/12/16 -N enhanced PAEK materials with Fern Plastic Products (injection moulded products)

7. 3/10/17 -Collab with Israel Aerospace?

8&9. 17/11/17 -Collabs with 2 of the world’s largest consumer groups to make N enhanced polymers for packaging

10. 4/12/17 -Agreement with US Fortune 100 chemical supplier - N and other 2D products in packaging?

11. 8/1/18 -Agreement with Global Apparel manufacturer (HQ Asia) - fabrics & high perf sportswear -INKS

12. 15/1/18 -LOI with Jinan/Shandong - planned Chinese manufacturing facility?

13. 27/2/18 -Collab with VivoBarefoot - N enhanced resins & fibres for footwear?

14. 14/3/18 -Collab with Team Sky - cycling products using N & INKS?

15. 27/3/18 -Collab with a world leading aerospace group - engines & mechanical systems & sensory devices - propeller initial £200k

?

16. 16/4/18 -European tyre manufacturer - initial order 500gr

17. 30/4/18 -Agreement with LUXUS (UK plastics manufacturer) N enhanced polymers for packaging, automotive, civil engineering sectors (AAC Cryoma, WMG)?

18. 29/5/18 -FTSE listed European manufacturer of consumer products for personal & household goods?

19. 8/6/18 -Collab with ArrowGreenTech - graphinks for PVA film, N banknotes & passports - (both exclusives) -tyre & rubber sectors (exclusive India only), 1st refusal on manufacturing plant in India

20. 18/6/18 -Collab with MediaDevil earplugs

?

21. 2/7/18 -Zap&Go supercapacitators

22. 2/7/18 -Flexibat - thin batteries for wearable devices (£145k funding granted)?

23. 2/8/18 -Collab with a top sportswear manufacturer - footwear & textiles?

24. 20/8/18 -Collab with AXIA - composite mats & smart graphene devices (N & INKS), S Korea, smart buildings & EVs?

25. 24/8/18 -AECOM US Fortune 500, large civil engineering structures - first SOW confirmed which includes the supply of 50 kg of graphene enhanced polymer material to be delivered in early December 2018 and a further 200kg early Jan '19 for final testing.

26. 1/10/18 -Completion of acquisition and collab with Gnanomat utilising Nanene for energy storage devices for use in EVs and portable electronic devices?

27. 18/10/18 -Collab with Advanced Insulation Ltd - sub-sea insulation materials, with a view to improving their tear resistance and reducing water absorption.?

28. 4/11/18 -Agreement with Qingdao Municipal Bureau of Commerce - Q to become one of the principal places to develop VRS' market in China - Q will assist VRS to form relationships with local businesses & identify investors - Q will help form a "Sino-foreign joint venture" which may include capital contributions.?

29. 7/11/18 -MOU with Tunghsu Optoelectronic Technology Ltd - upgraded to an LOI on 14/03/19 - the companies are to work together to manufacture in China new generation graphene heaters based on the micro-flow graphene ink technology and to develop other products utilising a variety of 2d materials, including graphene-enhanced sports equipment and smart wearable devices.

?

30. 15/11/18 -Major Global Airline - order for the supply of Versarien's graphene nanoplatelets to a design and manufacturing company for use in fire retardant aircraft interior parts which have gained the necessary certification from a Federal Aviation Administration (FAA) certified, fire testing laboratory.?

31. 19/11/18 - MOU with Jinan High-tech Financial Investment Co., Ltd - to establish a joint venture for the manufacture and sale of the Company's Nanene, Graphinks and other related graphene products in Jinan.?

32. - 04/12/18 -Polygrene launch - to enable us to offer customers an already compounded material incorporating graphene that they can use in existing production processes.

?

33. - 05/12/18 -MOU with China Tiesiju Civil Engineering Group Co Ltd. ("CTCE"), a subsidiary of China Railway Group Limited ("CRG"). - for use in anticorrosive and fireproof coatings, heat conductive and heating materials for the temperature control of structures, sensors for the mechanical monitoring of engineering structures, special engineering plastics, rubber and asphalt.?

34. 17/12/18 -GNA patent awarded which will enable the development of the technology needed to produce commercially viable graphene enhanced batteries and other energy storage devices.?

35. 09/12/18- Collab with large state-owned Chinese Aerospace Co. Nanene and other 2d materials including Hexotene.

36. 04/02/19 -MOU signed with another of China's Fortune 500 building materials companies to use our powders and inks for in flame-retardant applications, conductive shielding applications, the development and manufacture of new generation graphene heaters using graphene inks, winter sports equipment, specifically targeted at the 2022 Winter Olympic Games, smart wearable devices, including sensors and smart earphones, the incorporation of graphene into concrete, anti-corrosion coatings, 3D printing of concrete and certain rail projects, solar energy, photovoltaic cells and smart buildings and Gnanomat's proprietary nanomaterials into supercapacitors and lithium-ion batteries. Nanene graphene nano platelets has been satisfactorily tested by NGSIC.?

37. 07/03/19 - MOU with a second large state-owned Chinese aerospace company focussed on developing additional innovative products incorporating Nanene in to film materials and sensors.

38. Term Sheet with Beijing Institute of Graphene Technology which envisages that BIGT will provide funding to Versarien to establish a subsidiary company in China in the form of an equity investment in the Company, providing BIGT with a holding of up to 15% of the issued share capital of the Company.

The Team:

CEO - Neill Ricketts

CFO - Chris Leigh

Head of Commerce - David Kerr

NED - Iain Gray

Consultant- Nigel Laughton

Head of International Strategy and Government Relations - Matt Walker (secondee: Dept’ International Trade)

Deputy Head of International Strategy and Government Relations - Yi Luo (secondee: Dept’ International Trade)

Head of Research - Dr Stephen Hodge

Heads of Technology - Dr Denis Koltsov and Dr Martin Kemp

Cambridge Graphene Consultant - Mark Shepherd

Cambridge graphene technology Advisor - Professor Andrea Ferrari

Nomad & Broker - Cannacord Genuity Ltd

China contact - Bruno

Korean contact - Rachel Yeong-Mee Kim

Vice President of North American Operations - Patrick Abbott

AMERICA IDENTIFIES VERSARIEN GRAPHENE first to qualify.

1 April 2019

Versarien plc

("Versarien" or the "Company")

Completion of Verified Graphene Producer Programme

Versarien plc (AIM: VRS), the advanced materials engineering group, is pleased to announce that the Company is the first graphene company in the world to successfully complete the Graphene Council's "Verified Graphene Producer" programme (the "Programme").

The US-based Graphene Council's Programme is an independent, third party verification system that involves a physical inspection of the production facilities, a review of the entire production process, a random sampling of product material and rigorous characterisation and testing by a leading, international materials laboratory. The Programme is based on the most recent developments in globally recognised graphene standards, surveys of graphene producers, researchers and users, as well as analysis of commercially available graphene products.

The Graphene Council have designed the Programme to be an important step in providing customers and end-users with a degree of confidence, that has not existed before, that they are sourcing material from a reputable supplier, bringing transparency and clarity to a rapidly changing and opaque market for graphene materials.

Terrance Barkan, Executive Director of The Graphene Council, commented: "Successful commercialisation of graphene materials requires not only the ability to produce graphene to a declared specification, but to be able to do so at a commercial scale. It is nearly impossible for a graphene customer to verify the type of material they are receiving without going through an expensive and time-consuming process of having sample materials fully characterised by a laboratory that has the equipment and expertise to test graphene.

"The Verified Graphene Producer programme developed by The Graphene Council provides a level of independent inspection and verification that is not available anywhere else.

"We are pleased to have worked with the National Physical Laboratory (NPL) in the UK, regarded as one of the absolute top facilities for metrology and graphene characterisation in the world. They have provided outstanding analytical expertise for the materials testing portion of the Programme."

Neill Ricketts, CEO of Versarien, commented: "We are delighted that Versarien is the first graphene producer in the world to successfully complete the Graphene Council's Verified Graphene Producer programme.

"This is a huge validation of our technology and will enable our partners and potential customers to have confidence that the graphene we produce meets globally accepted standards.

"There are many companies that claim to be graphene producers, but to enjoy the benefits that this material can deliver requires high quality, consistent product to be supplied. The Verified Producer programme is designed to verify that our production facilities, processes and tested material meet the stringent requirements laid down by the Graphene Council.

"I am proud that Versarien has been independently acclaimed as a Verified Graphene Producer and look forward to making further progress with our collaboration partners and numerous other parties that we are in discussions with."

Enquiries:

Versarien

Neill Ricketts, CEO

Chris Leigh, CFO +44 (0)1242 269 122

Canaccord Genuity (Nominated

Adviser and Broker)

Bobbie Hilliam

Emma Gabriel +44 (0)20 7523 8000

IFC Advisory (Financial PR

and IR)

Tim Metcalfe

Graham Herring

Heather Armstrong +44(0)20 3934 6630

About Versarien

Versarien plc (AIM:VRS), is an advanced engineering materials group. Leveraging proprietary technology, the Group creates innovative engineering solutions for its clients in a diverse range of industries. Versarien has six subsidiaries operating under two divisions:

Graphene and Plastics

2-DTech Ltd, which specialises in the supply, characterisation and early stage development of graphene products. www.2-dtech.com

AAC Cyroma Limited, which specialises in the supply of vacuum-formed and injection-moulded products to the automotive, construction, utilities and retail industry sectors. Using Versarien's existing graphene manufacturing capabilities, AAC will have the ability to produce graphene-enhanced plastic products. www.aaccyroma.co.uk

Cambridge Graphene Limited, supplies novel inks based on graphene and related materials, using patented processes to develop graphene materials technology.

www.cambridgegraphene.com

Gnanomat S.L. ("GNA"), based in the Parque Cientifico Madrid, Spain, is a company capable of utilising Versarien's graphene products in an environmentally friendly, scalable production process for energy storage devices that offer high power density, almost instant recharging and very long lifetimes for use in electrical vehicles and portable electronics products.www.gnanomat.com

Hard Wear and Metallic Products

Versarien Technologies Limited has developed an additive process for creating advanced micro-porous metals targeting the thermal management industry and supplies extruded aluminium. www.versarien-technologies.co.uk

Total Carbide Limited, a leading manufacturer in sintered tungsten carbide for applications in arduous environments such as the oil and gas industry. www.totalcarbide.com

This information is provided by RNS, the news service of the London Stock Exchange. RNS is approved by the Financial Conduct Authority to act as a Primary Information Provider in the United Kingdom. Terms and conditions relating to the use and distribution of this information may apply. For further information, please contact rns@lseg.com or visit www.rns.com.

END

MSCSDFESFFUSEED

(END) Dow Jones Newswires

XG global sale chief quits. Joining Versarien instead. Patrick Abbott, global sales chief at XG Sciences will head up Versarien's new base at Houston.

Versarien comes to Houston. New US base.

hTTps://uk.advfn.com/stock-market/london/versarien-VRS/share-news/Versarien-PLC-USA-Update/79518660

RNS Number : 5552T

Versarien PLC

21 March 2019

21 March 2019

Versarien plc

("Versarien" or the "Company")

USA Update

Versarien plc (AIM: VRS), the advanced materials engineering group, is pleased to provide an update on the Company's activities in the United States of America.

Versarien has recently established a new US corporate entity, Versarien Graphene Inc, to facilitate the Company's graphene and other 2D materials activities in the USA. The Company is additionally in the process of establishing a new office, laboratory facility and applications centre in Houston, Texas that will act as a hub for the Company's activities in North America.

Patrick Abbott has been appointed as Versarien's Vice President North American Operations to oversee these activities and he will be based at the Company's Houston facility once established. Patrick is an experienced speciality materials professional with over 20 years' experience in the sector. He is a former US Marine Corps Officer who spent over 16 years in a variety of global business development and marketing roles at BASF. In 2015 and 2016, Patrick was part of the team transitioning specific product lines to Huntsman Corporation. Subsequently he established Global Marketing Empire Solutions, a disruptive technology consulting company and joined XG Sciences, a company focussed on graphene nano technology, as their global sales manager. At XG Sciences he was tasked with assisting the executive team in transitioning the company from an academic company to full commercialisation.

The establishment of this US presence follows on from work that Versarien has been undertaking with the US National Graphene Association and various collaboration partners in the region. Further North American potential collaboration partners and customers have been identified, both through inbound enquires and proactive approaches, and it is intended that the Houston facility and additional resource will enable these to be more efficiently progressed.

The Company is pleased to be participating in the UK Government organised "UK Technology and Capability Showcase" being held at Collins Aerospace in Charlotte, North Carolina, on 25 March 2019 where the Company will be presenting its 2D materials technology to Collins Aerospace representatives.

The Company additionally looks forward to being a leading participant in the American Graphene Summit, being hosted by the National Graphene Association (NGA) in Washington DC on 21 and 22 May 2019. The summit, keynoted by Senator Roger Wicker, intends to bring together leaders of US industry and government agencies and key international figures in the graphene sector to engage in a dialogue on shaping the global architecture surrounding graphene technologies and its impact on the US and global economy.

Zina Jarrahi Cinker, Executive Director of the National Graphene Association, commented: "The establishment of Versarien's first U.S-Based application development facility in Houston, Texas is a significant step for the development of graphene and graphene technologies in the United States. Versarien is a key member the elite Graphene Industry Council and I strongly believe Versarien Graphene Inc will be well positioned to serve the North American end user markets and facilitate the integration of graphene in strategic product segments."

Neill Ricketts, CEO of Versarien, commented: "We are very pleased to be moving to the next stage of our development in the US with the establishment of Versarien Graphene Inc and a dedicated facility in Houston.

"We are already pursuing a number of substantial opportunities in the US, particularly through the support of the National Graphene Association, and I expect our level of activity to significantly increase in the coming months, particularly given the high number of enquires we have had for the supply of our graphene and other 2D materials from leading US companies.

"I would like to express my sincere thanks to the support and assistance we have received from the National Graphene Association and Senator Wicker to develop our business and network in the US.

"I am also particularly pleased we have secured the services of Patrick Abbott and I would like to formally welcome him to the Versarien team. His skills and experience will be invaluable as we look to build more relationships and commercialise graphene enhanced products with US companies.

"Coupled with the recent progress we have made in China and elsewhere we remain confident that we can make further rapid progress this year. I look forward to providing further updates on our US and other activities in due course."

Enquiries:

Versarien

Neill Ricketts, CEO

Chris Leigh, CFO +44 (0)1242 269 122

Canaccord Genuity (Nominated

Adviser and Broker)

Bobbie Hilliam

Emma Gabriel +44 (0)20 7523 8000

IFC Advisory (Financial PR

and IR)

Tim Metcalfe

Graham Herring

Heather Armstrong +44(0)20 3934 6630

About Versarien

Versarien plc (AIM:VRS), is an advanced engineering materials group. Leveraging proprietary technology, the Group creates innovative engineering solutions for its clients in a diverse range of industries. Versarien has six subsidiaries operating under two divisions:

Graphene and Plastics

2-DTech Ltd, which specialises in the supply, characterisation and early stage development of graphene products. www.2-dtech.com

AAC Cyroma Limited, which specialises in the supply of vacuum-formed and injection-moulded products to the automotive, construction, utilities and retail industry sectors. Using Versarien's existing graphene manufacturing capabilities, AAC will have the ability to produce graphene-enhanced plastic products. www.aaccyroma.co.uk

Cambridge Graphene Limited, supplies novel inks based on graphene and related materials, using patented processes to develop graphene materials technology.

www.cambridgegraphene.com

Gnanomat S.L. ("GNA"), based in the Parque Cientifico Madrid, Spain, is a company capable of utilising Versarien's graphene products in an environmentally friendly, scalable production process for energy storage devices that offer high power density, almost instant recharging and very long lifetimes for use in electrical vehicles and portable electronics products.www.gnanomat.com

Hard Wear and Metallic Products

Versarien Technologies Limited has developed an additive process for creating advanced micro-porous metals targeting the thermal management industry and supplies extruded aluminium. www.versarien-technologies.co.uk

Total Carbide Limited, a leading manufacturer in sintered tungsten carbide for applications in arduous environments such as the oil and gas industry. www.totalcarbide.com

This information is provided by RNS, the news service of the London Stock Exchange. RNS is approved by the Financial Conduct Authority to act as a Primary Information Provider in the United Kingdom. Terms and conditions relating to the use and distribution of this information may apply. For further information, please contact rns@lseg.com or visit www.rns.com.

END

MSCSEMSMFFUSEDD

(END) Dow Jones Newswires

March 21, 2019 03:02 ET (07:02 GMT)

DNI Metals - Signs LOI to further develop its Vanadium / Polymetallic Alberta Black Shales deposit

ACCESSWIRE ACCESSWIRE•December 18, 2018

TORONTO, ONTARIO / ACCESSWIRE / December 18, 2018 / DNI Metals Inc. (DNI: CSE; DNMKF: OTC) ("DNI" or the "Company")

DNI's focus is Graphite in Madagascar, but due to the increase in certain battery metals pricing including the value of Vanadium, V2O5, from $5.89*per pound, in 2014, to over U$27.50 the increase of Cobalt, Co, from U$14.38* per pound, in 2013, to over U$25.06, the increase in Lithium, Li2CO3, from U$ 2.82* per pound to over U$30.00, DNI Metals Inc, is pleased to announce that a number of parties have shown renewed interest in its Black Shales Polymetallic deposit in Alberta.

Note: All the mineral prices have changed, the $Can/US exchange rate has changed, and input costs may have changed .*Prices as well used in DNI's resource report dated August 27, 2013.

Dan Weir, CEO, commented, "I want to emphasize that DNI is focused on developing its Graphite deposits in Madagascar. The previous management team and board of DNI did an amazing job, developing the Alberta Black Shales deposits. Over $6.7 million was spent on developing the deposits. The new team and I were treating the Black shales as a non-core asset. It is great to see the renewed interest in the project, and the worldwide demand for Vanadium."

Highlights of DNI's Vanadium and Polymetallic Resource in Alberta.

Several studies on the resources and economic significance of the deposits have been completed and a summary of selected results is presented below. Further details can be found on SEDAR”

Vanadium - Buckton South- Inferred Resource - Lower Portion - Second White Speckled Shale Formation

Vanadium - Buckton – Inferred Resource - Lower Portion - in Second White Speckled Shale Formation

Six Mineralized zones

DNI's Polymetallic Deposits – Battery and Electric car Metals

Letter of Intent

DNI has signed a Letter of Intent ("LOI") granting a private company ("Privateco") an option to earn up to a 51% interest in DNI's Alberta Black Shales Deposit. The LOI is generally non- binding, except for matters related to, among others, exclusive dealing and confidentiality.

DNI will grant to Privateco the option to earn an initial 51% interest in the Black Shales Property as follows:

upon execution of the LOI, Privateco is paying ONE HUNDRED THOUSAND dollars (Cdn$100,000) to DNI;

on or before the date which is the earlier of 6 months from the date of the Definitive Agreement or 15 days after the date that Privateco completes an RTO/IPO transaction, Privateco would pay an additional ONE HUNDRED FIFTY THOUSAND dollars (Cdn$150,000) to DNI; and

by incurring exploration and development expenditures on the Property of at least ONE MILLION dollars (Cdn$1,000,000) on or before March 31, 2021.

Privateco is controlled by Jim Atkinson in trust and without personal liability for a corporation to be incorporated. This is an arm's length transaction.

Dan Weir, CEO, commented, "Completing a deal with Privateco, will allow further development of its Vanadium / polymetallic assets, without sacrificing its Graphite Assets. We look forward to working with Privateco' s professional team."

DNI has also received interest from a First Nation group to purchase one claim of its eight claims of the Alberta properties and make the area into a provincial park. This could possibly include the area where DNI has its indicated resources, the Buckton zone.

Note: DNI is aware of six mineralization zones, 3 that have been drilled, and that the 3 stretch over 30 kms apart. The 6 form an even bigger area.

Black Shales – Vanadium

DNI Metals owns a Polymetallic black shales deposit in Alberta.

Mineral resources are hosted in two near-surface stacked black shale horizons which are mineralized with recoverable Mo-Ni-U-V-Zn-Co-Cu-Li-REEs-Y-Th-Sc and are partly exposed on surface. Six mineralized systems, or zones, have been identified on DNI's Property in northeast Alberta.

Two zones, the Buckton and the Buckton South zones have inferred resources and the Buckton has in addition indicated resources.

Asphalt Mineralized Zone. Three holes were drilled over the Asphalt Mineralized Zone, in 2011. It is located approximately 30 kilometres to the south of the Buckton Mineralized Zone.

Buckton South - March 1, 2013 Technical Report

The Maiden Resource Estimate for the Buckton South Zone, SBH Property Northeast Alberta prepared by APEX Geoscience Ltd. classified an inferred resource consisting of 548 million short tons (497 million metric tonnes) of mineralized black shale extending over 3.3 square kilometres beneath less than 75m of overburden cover. This resource is hosted in the Labiche Formation and underlying Second White Speckled Shale Formation, which are two flat-lying Formations that are stacked to comprise a continuous thick zone of mineralized shale. The inferred resource is mineralized with recoverable Molybdenum (Mo), Nickel (Ni), Uranium (U), Vanadium (V), Zinc (Zn), Copper (Cu), Cobalt (Co), Lithium (Li), Scandium (Sc), Thorium (Th) and Rare Earth Elements Lanthanum (La), Cerium (Ce), Praseodymium (Pr), Neodymium (Nd), Samarium (Sm), Europium (Eu), Gadolinium (Gd), Terbium (Tb), Dysprosium (Dy) and Yttrium (Y). The Resource Study estimates that the maiden inferred resource is overlain by 122 million short tons (110 million metric tonnes) of glacial till overburden cover.

Buckton - September 9, 2013 Technical Report

The Updated and Expanded Resource Estimate for the Buckton Zone SBH Property Northeast Alberta, prepared by APEX Geoscience Ltd. expanded the inferred resource at the Buckton Zone from 3.5 billion short tons to 4.9 billion short tons, in addition to upgrading a portion of it to the indicated resource class by delineating a 300 million short ton indicated mineral resource. The inferred and indicated resources together extend over 21.9 square kilometres (approximately a 3kmx8km area), 20.4 square kilometres of which represents the aerial extent of the inferred resource.

Asphalt Mineralized Zone – Exploration Target

Three holes were drilled over the Asphalt Mineralized Zone*, located approximately 30 kilometres to the south of the Buckton Mineralized Zone*. A number of additional planned drill holes were deferred, including holes intended to upgrade a portion of the Asphalt Mineralized Zone* (previously named the Asphalt Potential Mineral Deposit*) into an inferred resource, and holes intended to verify projected extensions of the Zone* which is open in three directions.

As outlined in the SBH Technical Report, the Asphalt Potential Mineral Deposit* holds potential for hosting 109-132 million short tons of polymetallic mineralization extending over 4.5 square kilometers and is open in three directions. The Asphalt Potential Mineral Deposit* was recently renamed as the Asphalt Mineralized Zone* to harmonize nomenclature with Jun30/2011 amendments to NI-43-101. Although based on drilling and nearby outcrop exposures, the Asphalt Mineralized Zone*, as better outlined in the SBH Technical Report, is a target for further ongoing exploration, it is conceptual in nature as there has been insufficient drilling conducted over the Zone* to define a mineral resource, and it is uncertain whether further drilling will define a mineral resource over the Zone*.

DNI’s current drilling reinforces geological extrapolations which suggest good continuity of mineralization within the Asphalt Mineralized Zone*.

Details of the drilling completed over the Asphalt Mineralized Zone* (holes 11AS01-11AS03) are tabulated below, showing analytical results, as well as comparative grades from adjacent historic holes 7AS01 and 7AS02.

Hole

Depth

Zone Width** (m)

Weighted Average Grade (ppm) ***

Specific

#

(m)

From-To

Width

Mo

Ni

U

V

Zn

Cu

Co

Ag

Li

Gravity

11AS01

51.0

26.8-37.9

11.1

116

203

47

786

352

88

30

1.0

75

2.38

11AS02

106.5

95.5-106.5

11.0

65

137

30

682

281

89

23

0.9

85

2.48

11AS03

32.5

Hole Lost in overburden in bad ground @ 32.5m depth

7AS01

76.3

7.1-18.5

11.4

73

144

47

690

376

89

20

0.3

na

na

historic

7AS02

89.8

21.6-33.2

11.4

63

122

31

664

282

89

20

0.3

na

na

historic

Hole

Depth

Zone Width** (m)

Weighted Average Grade (lb/st) ***

#

(m)

From-To

Width

Mo

Ni

U

V

Zn

Cu

Co

Li

[MoO3]

[U3O8]

[V2O5]

11AS01

51.0

26.8-37.9

11.1

0.23

0.41

0.09

1.57

0.70

0.18

0.06

0.15

[0.35]

[0.11]

[2.80]

11AS02

106.5

95.5-106.5

11.0

0.13

0.27

0.06

1.36

0.56

0.18

0.05

0.17

[0.20]

[0.07]

[2.43]

11AS03

32.5

Hole Lost in overburden in bad ground @ 32.5m depth

7AS01

76.3

7.1-18.5

11.4

0.15

0.29

0.09

1.38

0.75

0.18

0.04

na

historic

[0.22]

[0.11]

[2.46]

7AS02

89.8

21.6-33.2

11.4

0.13

0.24

0.06

1.33

0.56

0.18

0.04

na

historic

[0.19]

[0.07]

[2.37]

Note: See notes attached to information tabulated above for the Buckton Mineralized Zone*.

The drilling over the Asphalt Mineralized Zone* serves to confirm historic drilling results. The results reiterate uniformity of grades between the Asphalt and Buckton Mineralized Zones* which are located some 30km apart, and continuity of bulk average grades over distances ranging 300m-760m between holes.

In addition, the recent drill results indicate that tonnages previously estimated for the Asphalt Mineralized Zone* in the SBH Technical Report, relying on historic information, are understated. While an estimated specific gravity of 2.1, per historic work records, was relied upon by the SBH Technical Report to estimate potential tonnages which might be hosted in the Asphalt Mineralized Zone*, specific gravity of the Speckled Shale as measured from the above drill core samples averages approximately 2.4 and, accordingly, revises potential tonnages estimated for the Asphalt Mineralized Zone* from 109-132 million short tons of polymetallic mineralization to 125-151 million short tons. The above specific gravity figures are consistent with results from surface sampling completed by DNI during the past two years.

NI 43-101 Disclosure

The information in this press release was taken from previous press releases and technical reports filed on Sedar between the years 2010-2014.

In 2013, the technical information had been prepared in accordance with Canadian regulatory requirements by, or under the supervision of, the following independent Qualified Persons: Mr. Eugene Puritch P.Eng. (per P&E Mining Consultants Inc.), Mr. Michael Dufresne P.Geol. (per APEX Geoscience Ltd.) and Mr. Bruce Cron P.Eng. (per Cron Metallurgical Ltd.) DNI's previous Qualified Person in respect of its Alberta polymetallic black shale project is Mr. Shahé F.Sabag P.Geo., former President and CEO of DNI.

James Atkinson P.Geo, and Qualified person, has reviewed and approved the information contained in this press release. The reports prepared by the previous consultants were completed by competent, Qualified Persons and the present QP believes the information to be accurate.

Mineral resources are not mineral reserves and do not have demonstrated economic viability. There is no guarantee that all or any part of the mineral resource reported herein will be converted into a mineral reserve. An 'Inferred Mineral Resource' is that part of a Mineral Resource for which quantity and grade or quality can be estimated on the basis of geological evidence and limited sampling and reasonably assumed, but not verified, geological and grade continuity. The estimate is based on limited information and sampling gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes. The metal recoveries reported represent preliminary mineral recovery testing results collated from the collective bench scale laboratory testwork completed by DNI to date and may not reflect actual process recoverability that might be achieved in a mineral production operation, all of which is the subject of ongoing studies.

DNI – CSE

DMNKF - OTC

Issued: 122,098,403

For further information, contact:

DNI Metals Inc. – Dan Weir, CEO 416-595-1195

DanWeir@dnimetals.com

Also visit www.dnimetals.com

Forward-looking Statements

https://finance.yahoo.com/news/dni-metals-signs-loi-further-113800297.html

FTMIG Interviews Warwick Smith, CEO & Director of American Pacific Mining Corp! (CNX: USGD)

https://www.ftmig.com/portfolio-view/ftmig-interviews-warwick-smith-ceo-of-american-pacific-mining-corp/

Karl Boyd is joined by guest-host Eden Broda, today to have an in-depth interview with Warwick Smith, CEO and Director of American Pacific Mining Corp! We get to find out why their new project is so exciting and what makes USGD stand out from the rest! #USGD #USGDF

LIVE STREAM of our show will be available on our FTMIG LIVE page at the following link: https://www.facebook.com/Followthemoneyinvestorgroup

TUNE IN every Wednesday from 1-3pm EST on Midas Letter (midasletter.com) where we bring you the most current interviews, special guests, T.A., and discussions on the most interesting companies in the hottest sectors.

Join our FREE membership for access to EXCLUSIVE early-round investment opportunities!

** https://www.ftmig.com/membership

Built by investors, for investors. Be in the know and FOLLOW THE MONEY!

FULL VIDEOS will also be available on our website at www.ftmig.com and don’t forget to Like, follow, and share our FTMIG LIVE page, YouTube, and Twitter for all our exclusive videos and updates!!

https://www.twitter.com/FTMInvestment

https://www.YouTube.com/Followthemoneyinvestorgroup

https://www.Facebook.com/followthemoneyinvestorgroup

https://www.ftmig.com/portfolio-view/ftmig-interviews-warwick-smith-ceo-of-american-pacific-mining-corp/

Versarien today announce global collaboration with Advanced Insulation. Today the company issued a formal stockmarket announcement of a tie-up with a company specialising in extreme protection of at-sea and below-sea oil and gas facilities worldwide.

Versarien IS the real deal for Graphene. Well done Grabster. A number of USA companies are already in collaboration & testing it. Just one large order & this share will start to motor. Bazzerp (Still in Namibia).

Nanene - is the trade name for Versarien's graphene & it's fantastic

Stuff!

Do you invest in companies were you find out twice a year what goes

On, get bored & sell?

Versarien has a dedicated, honest CEO, Neill Ricketts, who you can follow daily on Twitter.

Versarien is on the London AIM market & well worth the effort to research it.

In the UK, Investors Hub has a sister site called Advfn where there is an extremely helpful discussion thread about Versarien, titled 'VRS the world lead in real graphene (Nanene)'. The header for that thread contains a huge amount of relevant information for newcomers wishing to research this stock.

GRAPHENE PROGRESS. Versarien is the real deal. In the 14 years since graphene was first developed at Manchester University in the UK, there's been a wild-west style goldrush among companies worldwide to get it into production. Many claim to have done so. But many of those claims are false. Customers have, in many cases, been sold material purporting to be graphene, but which has not performed well. In some cases the ingredient has produced improvements, but not the exciting ones expected. Fast-forward to September 2017 when the International Standards Organization (ISO) published a long overdue definition of what can and cannot be called graphene. More than 90% of the material previously marketed as graphene fails to comply - which helps explain the disappointments experienced. In many cases the material sold has been graphene oxide or other derivatives of graphite. These do have their uses, but they are not graphene. One of the companies whose product does comply at the highest grade is small UK company called Versarien. This is no surprise to its followers, as in Sept 2017 it was the runaway winner of a UK tender in which samples were submitted to the government's Centre For Process Innovation. The company began by buying 85% of a graphene company set up by Manchester University - the birthplace of graphene. The university maintained a 15% stake in Versarien.

3 Oct 2016 - acquired plastics company Aac Cyroma

19 Jan 2017 - acquired 85% of Cambridge Graphene Ltd, the remaining 15% being retained by Cambridge University with whom Versarien have an ongoing research relationship.

8 Feb 2017 - The brand name Nanene is registered for Versarien's graphene.

19 Sept 2017 - Versarien wins UK government tender to supply graphene after submitted samples proved superior.

15 Jan 2018 - China's Jinan Province sign a Letter Of Intent for a joint venture with Versarien, to meet growing need for genuine graphene which China's own makers have failed to produce.

5 Feb 2018 - America's National Graphene Association (NGA) appoint Versarien's boss Neill Ricketts to its Advisory Board.

22 May 2018 - in an unprecedented move, the UK government announce that Matt Walker, Head of Outward Direct Investment at the UK Government's Department for International Trade ("DIT") has joined Versarien on a secondment for a minimum of 12 months. During this period he will work exclusively for Versarien and will be Head of International Strategy and Government Relations.

7 Jun 2018 - the NGA announce that Versarien has been appointed as the inaugural Industry Council member and Corporate Partner of The National Graphene Association ("NGA"), the main organisation and body in the US advocating and promoting the commercialisation of graphene.

15 Aug 2018 - UK government announce that Peter Jay, Head of Policy and Governance for Outward Direct Investment at the UK Government's Department for International Trade ("DIT") has joined Versarien on a secondment for a minimum of 12 months. During this period he will work exclusively for Versarien and will be primarily responsible for overseeing the Company's planned People's Republic of China expansion implementation.

25 Sep 2018 - Versarien buys a 62% stake in Spanish advanced battery and supercapacitor developer Gnanomat.

Check out the 'About us' page on the company website, and the 'rns' list in the 'Investors' section for details of more than two dozen active collaborations under way with partners ranging from innovative small companies to global corporations. With assistance from the UK government, the company is also finalising huge deals with China.

The company is listed on the London Stockmarket (ticker LSE:VRS) where it's stock price has climbed 12-fold in 12 months.

OTTAWA & SINGAPORE – 18 September 2018 — Grafoid Inc. (“GRAFOID”) is pleased to announce the strategic partnership with Liquinex, a company specializing in waste water engineering needs, to provide commercial scale water treatment solutions using Grafoid’s innovative MESOGRAF™ graphene- based filtration technology.

The increasing demand for clean drinking water, rising scarcity of water resources, rapid industrialization, and increasing construction activities represent real-world factors that necessitate the need for scalable water treatment solutions around the globe.

Compounded by other factors, such as the increased support from government regarding treatment and proper disposal of water, the global market for water treatment solutions is expected to grow at an annual compounded growth rate of 7.4% from 2017 to 20271.

GPURE’s Graphenegraphene- based filtration products are readily scalable to meet these commercial demands making them ideal for industrial level, niche applications such as the concentration of beverages, treatment of crude oil/water mixtures, biofuel and industrial wastewater treatments where reverse osmosis (RO) is not suitable due to the fouling tendencies when concentrated liquids are purged through RO cartridges.

Conventional filtering materials (e.g. activated carbon, zeolites, flocculants etc.,) have certain limitations of pH-sensitivity, poor efficiency and recoverability to treat a mixture of wide variety of contaminants present in the wastewater. In contrast, MESOGRAF™ graphene, being a 2D-material with high surface-area and functional-group tunability, exhibits outstanding adsorption and recyclability capabilities for a wide variety of contaminants.