Monday, May 16, 2011 5:32:54 PM

Latest Developments:

JBII to be a Tour Destination hosted by Canadian Plastics Industry Association (CPIA) on Thursday, May 26, 2011.

Tour of Recycling & Waste Recovery Facilities, Niagara Falls Region:

Visit # 3: A pilot plant showcasing an emerging technology that converts residual plastic waste into fuels.

JBI, Inc. (Plastics to Oil plant), 20 Iroquois Street, Niagara Falls, NY, USA

JBI converts plastics-to-fuel and natural gas, ensuring that the embedded energy in residual plastics is managed and conserved

as an important and useful resource, rather than treated as a disposable waste. JBI’s fully automated process vaporizes plastics and

cracks their hydrocarbon chains using a proprietary catalyst. The New York Department of Environmental Conservation (NYDEC)

has recently granted the plant a consent order to operate commercially.

http://www.plastics.ca/home/events/recyandwasettour.php

5-9-2011: JBII First Fuel Sales to Occidental Petroleum (NYSE:OXY)!:

JBI, Inc. (the "Company" or "JBII") (OTCQX:JBII) announced today that Oxy Vinyl Canada, a wholly owned subsidiary of Occidental Petroleum (NYSE:OXY),

has agreed to purchase JBI's low sulphur heating oil for $109.80 per barrel. Low sulphur heating oil is a product of our Plastic2Oil™ process.

Under the terms of the agreement, the first order of approximately 214 barrels of low sulphur heating oil is expected to be delivered this week.

http://www.oxy.com/Pages/Home.aspx

http://finance.yahoo.com/news/JBI-Inc-to-Supply-Oxy-Vinyl-pz-404707702.html?x=0&.v=1

5-2-2011: JBII Enters into Referral Agreement With Smurfit-Stone (NYSE: SSCC):

Smurfit-Stone is a multi billion dollar company: http://www.smurfit.com/

Smurfit-Stone clients to be referred to JBII and JBII will install processors at their facilities.

http://www.otcmarkets.com/edgar/GetFilingHtml?FilingID=7897367

4-27-11: JBII CEO on BNN 'The Pitch'. High Points:

. $587K/processor

. $2-3M RD costs

. Being innundated with requests to bolt down machines at high waste plastic feed sources

. Process is Green. Emissions less than a gas furnace.

. Filing prospectus with TSX next week

. Filing 5 patents on the process.

. Upgraded to an accounting firm that can file both Canadian and US.

. Agreements gone through legal with a large cardboard recycler that generates a huge amount of plastic. 30 Tons/day.

. Make spec fuel. Comes out of the machine that way. Directly to commodity price.

. Sales this week.

. Filling tankers now.

. Revenues Q2.

4-20-11: 10K Released. Interesting excerpt found by Steady_T:

"It is possible that industrial partners may wish to provide financing for the construction and other costs associated with building and operating a P2O processor."

Translation.....If you want one any time soon, finance it for us. That way you can start saving money a lot sooner.

Very nice way to obtain capital.

4-20-11: 8K/PR Released. Excerpts:

The Company notes that on March 16, 2011 it signed a non-binding letter of intent with a potential customer for the purchase of the naphtha produced from the Company's Plastic2Oil process. At this time, a definitive fuel supply agreement is being negotiated

Additionally, on April 14, 2011, after much discussion and exchanges of drafts, the Company received what management believes is a final referral agreement with a large company that has a significant number of material recycling facilities and high volume waste plastic streams.

Additionally, JBI has been negotiating Joint Venture agreements with both the aforementioned company and one of its customers. These companies have sent in excess of 141,640 lbs of waste plastic to date. This plastic was processed and evaluated for qualitative and quantitative analytical data. Over the last few months, JBI has met with executives and representatives from these Companies at their respective locations and our Plastic2Oil factory.

The contemplated structure of a Joint Venture with JBI is:

· JBI will build and operate a Plastic2Oil processor at the source of the plastic waste.

· JBI will receive plastic waste at no cost.

· JBI will share in the revenue from the sale of fuel generated by the machine, 80% / 20% (JBI receives 80%).

· As JBI staff will operate the process, JBI will assume all risks.

http://www.otcmarkets.com/edgar/GetFilingHtml?FilingID=7870575

4-13-11:

JBII attended and John Bordynuik gave a presentation at the Air and Waste Management Association Seminar on April 13. Among the attendees

were Waste Management Inc, Conestoga-Rovers &Associates, and URS.

Report from the Conference. Thank you Justice!:

The presentation was well received and you were right, no material information was disclosed.

I have a few notes I want to share as there was some new information. Another company has tested the fuel, the Alberta Research Council. They are the Gold Standard in Canada when it comes to testing fuel. Guess what, just like we have been told all along, JBI produces light naphtha (pure unblended gasoline) and diesel #2. There is one difference, the fuel is even cleaner now. Previously the sulfur content was 8 parts per million, it now has 0.5 parts per million (500 parts per billion) and no sediment or water content. The ratio of diesel and gasoline is 70% and 30% (and yes the fuel is separated during the P2O process). John is still reporting that the fuel is produced for less than $10 a barrel.

One of the questions after the presentation was if a car used the JBI fuel would it void the warranty. The answer was JBI fuel would absolutely not void a warranty, the fuel is no different than what you would get from a refinery. It started out as fuel and is converted back into fuel.

John was asked about how much a recycling facility would save if they had a P2O processor and the answer was that some large facilities send 170 tons of plastic to landfill per day. Smaller facilities send 120 tons per day.

Now I figure that for a large recycling facility, if JBI only processes half that amount, just to be extremely and overly conservative, using the average tipping fees in the states as a base, $43 per ton, a large facility saves $3655 a day in tipping fees and that does not include transportation costs. Taken to a five day work week, it's just under a million dollars a year, again this does not include transportation costs (truck, fuel, driver).

The JBI staff at the presentation were extremely upbeat and enthusiastic about what has been happening recently and look forward to when they can let us know what all the new developments are.

Letter of Intent for 144,000 Gallons/Week

The company has signed a letter of intent with a confidential party for the purchase of 144,000 gallons of naphtha per week.

Naptha is produced from the Company's Plastic2Oil process and is the technical term for gasoline without the additives that pump gas has.

The sales agreement is expected to be signed in April, 2011.

Extensive improvements have been made to the P2O processor:

Since receiving the Consent Order, JBI has simplified the configuration of the Plastic2Oil process using modular racking.

The modular racks are prewired and plumbed, and constructed as complete units to simplify installations and reduce costs at remote sites.

Also since receiving the Consent Order, our Plastic2Oil process has been extensively and successfully stress tested to ensure its operational integrity

in preparation for operations at remote sites.

2 IHub Shareholders (Brigg and Rawnoc) recently visited the facility and reported their observations and thoughts.

Their reports verify that there is an unending supply of waste plastic available, that the machine is running non stop,

that employee morale is extremely high, and the quality of the output is everything the company has said it is.

In short, both of them are impressed to the nth degree.

Brigg has also tested the gasoline which came straight from the P2O processor. Results: Ran in a lawnmower like a champ!

Extensive DD and Information: http://www.jbiglobal.blogspot.com/

JBII just fired Ernst and Young for apparently not giving the company the attention that was expected:

we performed only limited audit planning procedures during this period and we did not report on any financial statements of the Company.

Yours truly,

/s/ Ernst & Young LLP

The company has hired MSCM LLP, auditors that will give JBII a higher priority in addressing their needs:

MSCM, LLP has differentiated themselves for JBI by offering a responsive, partner-led audit team that has proven to us practical and timely client services.

MSCM, LLP also has the international proficiency to meet the needs of JBI's future growth. MSCM Web Site: http://www.mscm.ca/

1. Commercial Production has been approved by the NY DEC. (Only time in history a company has been given commercial production

approval while other permits are pending).

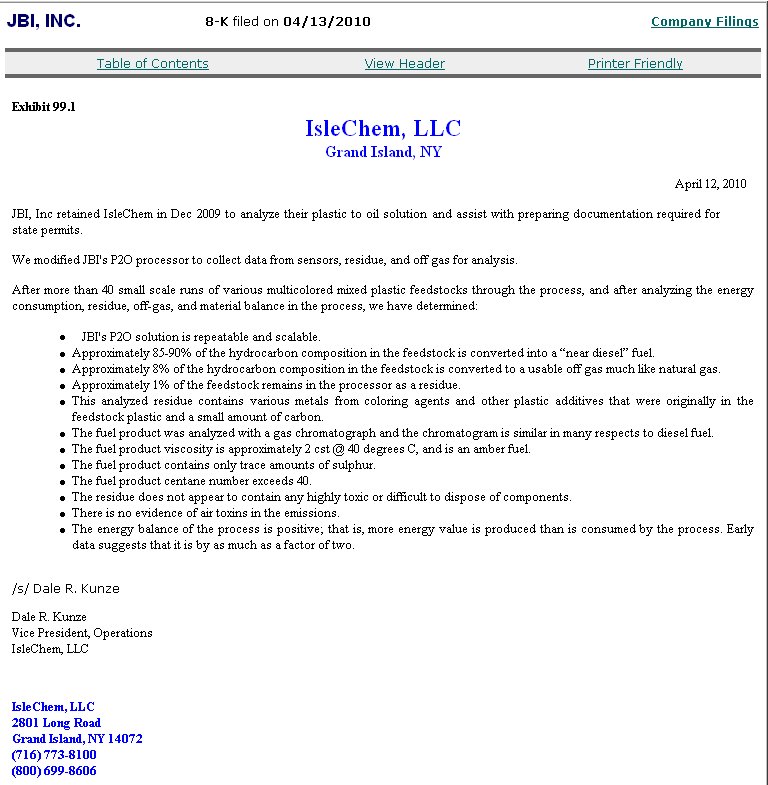

2. The process has been proven to work by at least 3 independent firms.

3. Two NY Senators have endorsed P2O.

4. Each processor will generate 100+ Barrels of fuel daily.

5. 2 more processors are being built.

6. JBII owns an operational Fuel Blending Facility with a storage capacity of 250,000 gallons.

7. Company just signed a 20 year lease on A waste management recycling facility with 1,000 Ton/Day capacity.

8. Colin Robbins recently appointed as Sr. Vice President:

Mr. Robbins brings more than 30 years of knowledge and expertise in operations, marketing, and manufacturing of renewable fuels to this key post.

He specializes in the blending of ethanol, bio-diesel, butane, and petroleum. He has been engaged in the petroleum and bio-fuels industry

in a leadership capacity since 1989 with experience extending across North America--but he is most passionate about

producing a profitable, environmentally responsible energy product.

9. Waste Management Inc. is currently doing an audit on the process.

Feast your eyes on this 3 minute clip:

JBII: It's Raining Diesel:

Just listen to the excitement in their voices!

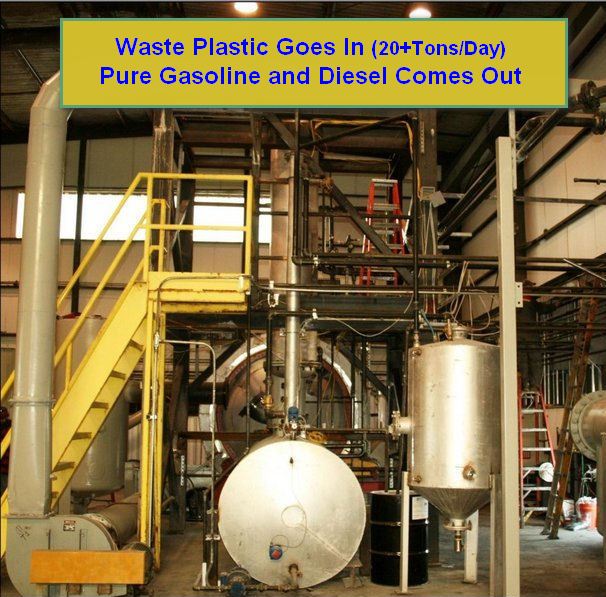

JBII Fuel Output from 20 Ton Production Processor:

Free Plastic Stockpiled and ready for Processing:

Firing up the lawnmower with JBII gasoline! From Techisbest:

My unrehearsed video:

This lawnmower has not been run this season. The smoke you see when I first fire it up is from it sitting idle. Note that the longer it runs the cleaner it runs.

The jar used is the one on the left in this pic:

Fuel Ouput:

Validation:

Plastic2Oil Why Us

We are a domestic alternative fuel company that developed, scaled, enhanced, and commercialized a process that converts difficult-to-recycle waste plastics into separated, refined fuels. We have successfully overcome significant barriers in this field, namely:

* Our process accepts mixed waste plastics.

* Our process is continuous, 20T/day and small (less than 1000 sqft)

* Residue is removed automatically without shutdown.

* The product is refined and separated fuels without the high cost of a distillation tower.

* Our equipment is not susceptible to costly pinhole leaks.

* Our process operates at atmospheric pressure.

* Our process is permitted to use its off-gas as fuel (8% of feedstock) therefore conversion costs are very low: 67kWh electricity for motors, and pumps, and approx. $7/hr for natural gas top up (if required).

* Significant labs have validated our technology: IsleChem (process), CRA (Stack Test), Intertek and Petrolabs (fuel testing), and a rigorous permit process with the NYSDEC (NY State).

* Our emissions are less than a natural gas furnace. We are not required to monitor our emissions or install scrubbers.

* Fuel additives are injected inline while the fuel is produced.

* We have significant downstream technology to ensure fuel quality control.

EMail to Techisbest:

Nice to hear your lawnmower ran well with the fuel tapped directly off our gasoline condenser.

Our gasoline is no different than highly refined gasoline from a refinery. Our gasoline is different than gas found at the pump because we do not inject the additives and low cost cutting agents (butane injection), aromatics, and other additives to artificially inflate the octane thereby reducing the amount of high-cost gasoline. Many additives are injected in pure gasoline to increase the margin on gasoline at the pump. Our fuel was tested in a new engine long ago and the spark plug, head, valve seats and valves were inspected. There was no carbon build up, pitting, burns, or oxidation on those parts. We were quite impressed by how cleanly it burned.

Regards,

John Bordynuik

z

Axis Technologies Group and Carbonis Forge Ahead with New Digital Carbon Credit Technology • AXTG • Apr 24, 2024 3:00 AM

North Bay Resources Announces Successful Equipment Test at Bishop Gold Mill, Inyo County, California • NBRI • Apr 23, 2024 9:41 AM

Epazz, Inc.: CryObo, Inc. solar Bitcoin operations will issue tokens • EPAZ • Apr 23, 2024 9:20 AM

Avant Technologies Launches Advanced AI Supercomputing Network and Expansive Data Solutions • AVAI • Apr 23, 2024 8:00 AM

BestGrowthStocks.com Issues Comprehensive Analysis of Triller Merger with AGBA Group Holding Limited • AGBA • Apr 22, 2024 1:00 PM

Cannabix Technologies to Present Marijuana Breathalyzer Technology at International Association for Chemical Testing (IACT) Conference in California • BLO • Apr 22, 2024 8:49 AM